The die cutting machine market is growing fast. This is because more people want packaging and printing. Recent numbers show this growth:

| Year | Market Size (USD) | CAGR |

| 2024 | 1.8 Billion | N/A |

| 2025 | 1.9 Billion | 5% |

| 2034 | 3 Billion | N/A |

These numbers are important for makers, sellers, and investors. Oyang is a top company for smart packaging solutions. Some big trends in the market are:

Key Takeaways

The die cutting machine market will grow a lot. It may reach USD 1.9 billion by 2025.

Automation and smart technology help companies work faster. These tools also help reduce waste.

Sustainability is very important now. More businesses want eco-friendly machines. They need to follow environmental rules.

Asia-Pacific is growing the fastest in this market. There are more factories and more need for custom packaging.

Oyang is the top company in the market. They offer new, efficient, and green die cutting solutions. These solutions fit many industry needs.

Die Cutting Machine Market Growth Rates

![Die Cutting Machine Market Growth Rates]()

Image Source: unsplash

Current Market Size and CAGR

The die cutting machine market is getting bigger every year. Many companies use die-cutters for packaging and printing. This makes more people want these machines. The market size and growth rate show why die-cutters matter.

Industry experts use CAGR to see how fast the market grows. CAGR helps people plan for future investments. The table below shows CAGR from different reports:

| Source | CAGR | Period |

| Die Cutting Equipment Market | 5.3% | 2024-2033 |

| Die Cutting Machines Market | 2.1% | 2023-2032 |

This shows the die cutting machine market is growing well. The growth rate depends on things like new technology and more packaging needs. Companies use this information to know when to buy new die-cutters.

Future Projections and Trends

Experts think the die cutting machine market will keep growing. The projected CAGR is 4.7% from 2025 to 2031. This means more businesses will need die-cutters. The market will give new chances to makers and buyers.

Some trends will change the die cutting machine market:

Smart automation and Industry 4.0 are changing die cutting. IoT lets people watch machines in real time. This helps stop problems and makes work faster. Machine learning helps make products better and cuts down waste.

Better automation and digital tools help die-cutters work faster and better. Many companies want machines that save energy and make less waste. This helps the demand for eco-friendly die-cutters grow. More businesses want custom machines for their needs.

IoT and AI are making die cutting more efficient. Real-time monitoring and data help fix machines before they break. This makes work smoother and helps the market grow.

Key Drivers in the Die-Cutter Market

![Key Drivers in the Die-Cutter Market]()

Image Source: pexels

Technology and Automation

Technology and automation are big reasons the die cutting machine market is growing. Many companies buy new machines to make things better. These machines help workers finish jobs quickly and with fewer mistakes. Automation lets businesses make more products in less time. It also helps them save money and fill big orders.

Automation in die-cutter work has many good points:

The table below shows how different technologies help the market:

| Technological Advancement | Impact on Market Growth |

| Automation | Makes production faster and more exact |

| Digital Technology | Gives more ways to change and adjust products |

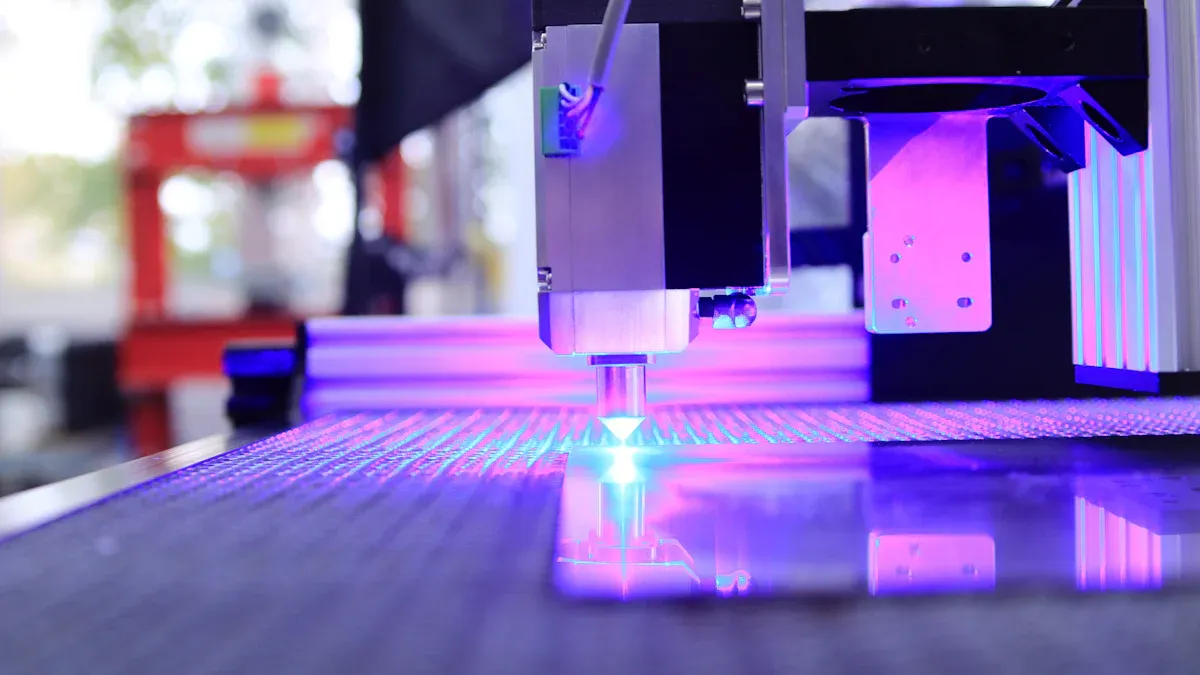

| Laser Die Cutting | Cuts fast without touching, so work goes quicker |

| Rotary Die Cutting | Works with many materials and lasts a long time |

Manufacturers pick die-cutters with these features to stay ahead. They want machines that can do many jobs and keep up with changes. Technology helps the die-cutter market by making work faster and better.

Sustainability and Eco-Friendly Packaging

Sustainability is another big reason the die-cutter market is growing. Many places, like Europe and North America, have rules to use less energy and make less waste. Companies now want machines that use eco-friendly materials and save power. More people want packaging that is better for the planet.

Die-cutters help companies use less material for packaging. They also let companies use recycled materials, which are hard to cut by hand. Die-cutters can make boxes that fit products better, so there is less waste.

The die cutting machine market grows as more companies want to meet green rules. Manufacturers use die-cutters to follow new laws and keep customers happy. These reasons help the market get bigger in the future.

Market Challenges and Restraints

Investment and Cost Barriers

Many companies have trouble joining the die-cutter market. Buying advanced machines costs a lot at first. Small and medium businesses find it hard to pay for these machines. The cost is not just for the die-cutter itself. Companies also need money for tooling and keeping machines working. Skilled workers are needed to run these machines. It is hard to find people who know how to use new technology. This makes things even harder for businesses. These problems slow down market growth. Smaller companies get less market share because of these barriers.

Companies want machines that work well and last long. They also want machines that do not need much fixing. This helps them save money and meet demand.

The main cost problems are:

Advanced die-cutters cost a lot to buy

Tooling and maintenance need extra money

Skilled workers cost more to hire and train

Small businesses have trouble competing with big ones

Competition and Alternatives

The die-cutter market has lots of competition. Other technologies like laser cutting and digital die-cutting are popular. Rotary die-cutting is also used by many companies. These options help companies work faster and make better products. They also help with custom orders.

| Technology | Advantages | Use Cases |

| Laser Cutting | Very exact, works with many materials | Detailed designs, custom items |

| Digital Die-Cutting | Costs less for tools, good for small businesses | Small batches |

| Rotary Die-Cutting | Very fast, good for making lots of things | Big manufacturing jobs |

Competition makes companies try new ideas. They make die-cutters better to meet what buyers want. Automation and AI help save time and money. This means products get better and prices go down. The market keeps growing because of this.

Digital die-cutting machines help make things faster. Buyers pick these machines to work quickly and fill orders.

Manufacturers must use new technology to stay ahead. They work on making die-cutters that are strong and work well. This helps them get more market share. It also helps them meet the need for better packaging solutions.

Global Die-Cutter Market Segmentation

By Machine Type

The global die-cutter market has a few main machine types. Rotary die-cutters are good for fast and steady work. Flatbed die-cutters make exact cuts and are great for changing designs often. Digital die-cutters use computers to cut things in many ways. Each type helps with different jobs in the market.

Rotary die-cutters: They work quickly for big orders.

Flatbed die-cutters: They are best for small jobs and detailed cuts.

Digital die-cutters: They are easy to set up and good for custom work.

Oyang makes all these kinds of die-cutters. Their machines use smart technology for accurate cuts and quick changes. Oyang’s equipment helps companies work faster and handle new needs.

By Application

Die-cutters are used in many areas. In packaging, they make boxes, labels, and inserts to protect products and look nice. Printing and stationery companies use die-cutters for cards and book covers. Car and electronics companies need die-cutters for parts like gaskets and insulation. People also use die-cutters for crafts and decorations.

| Industry | Application Description |

| Packaging | Boxes, labels, inserts for products |

| Printing and Stationery | Greeting cards, business cards, book covers |

| Automotive/Electronics | Gaskets, insulation, components |

| Crafts and DIY | Custom decorations, scrapbook elements, fabric appliqués |

Oyang’s machines help with these jobs by being accurate and working with many formats. Their machines also help save energy and reduce waste. Companies use Oyang’s solutions to make new packaging and printed items.

By End-Use Industry

Many industries use die-cutters. Food and beverage companies use them for safe packaging. Consumer goods brands need special boxes and labels. Medicine companies need careful packaging for safety. Clothing and industrial companies use die-cutters for tags and protective packaging.

Food and Beverage

Consumer Goods

Pharmaceuticals

Apparel

Industrial

Oyang is a leader in making smart and green die-cutters for these industries. Their machines help companies save money and work better. This helps the die cutting machine market grow around the world.

Regional Insights for Die Cutting Machine Market

Asia-Pacific Trends

Asia-Pacific is growing fast in the die-cutter market. More factories and higher incomes help sell more digital die-cutters. Many young people like DIY projects. This makes small die-cutters popular. Online shopping is getting bigger. This means companies need better packaging. Businesses compete by adding smart features and easy software. They try to make their products different and set good prices. This helps them get more customers. The die-cutter market in Asia-Pacific keeps getting bigger every year.

North America Overview

North America’s die-cutter market grows at a steady pace. People want better packaging and cool products. Companies use new technology to meet these needs. Better ways to make and deliver products help businesses work faster. The market gets stronger as people want new things. Many companies buy advanced die-cutters to keep up.

Europe Market Dynamics

Europe’s die-cutter market is known for new ideas and rules. Many things affect the market:

More people want good packaging

New technology makes die-cutters better

Helpful rules support the market

Companies use new solutions

People want eco-friendly products

Better ways to make and deliver products

Risks from rule changes, money problems, and other options

These things help the market grow. But companies must watch for new rules and changes in the economy.

Other Regions

Latin America and the Middle East & Africa have smaller die-cutter markets. But both places are growing slowly. In Latin America, packaging and textiles need more die-cutters. The Middle East & Africa use die-cutting for car parts and medical tools. These markets are small but keep growing. More industries see how die-cutters can help.

Competitive Landscape and Leading Brands

Oyang's Market Position

Oyang is a top company in the die-cutter market. People know Oyang for smart machines and green solutions. Their machines are very accurate and work fast. Oyang’s team has worked on research for over 20 years. They make new software and hardware for die-cutters. Oyang gives quick help after you buy their machines. Their support team is always ready to help. Oyang’s die-cutters can cut many kinds of packaging materials. This makes them useful for lots of jobs.

Oyang sells machines all over the world. They have put more than 2,000 die-cutters in different factories. In 2024, Oyang bought Wenhong Machinery. This made Oyang even stronger. Wenhong knows a lot about post-press automation and carton converting. Now Oyang can offer more solutions and stay ahead. Oyang cares about new ideas and saving the planet. This helps them lead the die cutting machine market.

| Key Differentiators | Oyang Features | Competitor Features |

| Focus on Intelligent Equipment | High precision and efficiency | Varies by brand |

| R&D Capabilities | 20+ years of experience | Varies by brand |

| After-Sales Service | Instant support team | Varies by brand |

| Application Versatility | Works with many packaging materials | Varies by brand |

Major Players and Innovations

Many big brands compete in the die-cutter market. They add new features and technology to their machines. Some trends are changing the market:

Companies want machines that can be customized.

Brands use green materials to look better.

Automation and robots help save money and work faster.

New ideas in the die-cutter market include:

AI and automation make work easier.

Eco-friendly materials meet new needs.

Automated die-cutters and lasers cut very well.

Digital die cutting makes less waste and works fast.

3D cutting helps with hard designs.

Smart die-cutters with IoT make fixing easy.

These changes help the market get bigger. Companies that use new technology and care about the planet do well. Oyang’s success, worldwide sales, and smart die-cutters set a high goal for other brands.

The die cutting machine market keeps growing as more people want better packaging.

Automation, Industry 4.0, and caring for the environment help the market grow.

These machines can do many jobs for packaging, cars, and electronics.

Companies need flexible machines for custom orders and small batches.

Asia-Pacific grows fastest because it has many factories.

Oyang is a leader because they make smart, green machines that work very well. They always try new ideas and listen to what customers want. This helps other businesses do well too.

| Opportunity/Advancement | Description |

| Customized Packaging | More companies want special packaging, so new machines are made. |

| E-commerce Growth | Online shopping means more need for fast, exact cutting. |

| Sustainability Focus | Caring for the planet brings new chances for the market. |

| IoT and AI Integration | Smart tech helps machines work better. |

| Automation | Fully automatic machines help companies make more things. |

FAQ

What materials can die cutting machines process?

Die cutting machines can cut paper and cardboard. They also work with corrugated board and cartons. PET film is another material they can handle. Companies use these machines to make packaging. Packaging comes in many shapes and sizes.

Where do businesses use die cutting machines?

Businesses use die cutting machines for packaging and printing. They also use them in automotive and electronics. Crafts are another area where these machines help. Die cutting machines make boxes and labels. They also make cards, gaskets, and decorations.

How long does delivery take for Oyang die cutting machines?

Oyang delivers machines in one or two months. This happens after they get the deposit. Delivery time can change if the order is big. Location also affects how long delivery takes.

What support does Oyang offer after purchase?

Oyang gives quick help after you buy a machine. Their team helps with installation and training. They also give technical advice. Customers can reach Oyang by email or phone. WhatsApp is another way to contact them.

How many die cutting machines has Oyang installed worldwide?

Oyang has put over 2,000 machines in factories. These machines work all the time. Many industries use Oyang’s die cutting and creasing machines.