Choosing the right machine for your paper bag making needs while staying within budget can be challenging. You want a machine that delivers good performance and reliable support, but you also need to keep your spending low. When it comes to choosing the right machine, you may encounter some common issues. It’s essential to ensure that the machine operates efficiently and smoothly. You should assess its performance capabilities and understand the actual costs associated with its operation. Additionally, it’s crucial to determine whether the manufacturer will provide assistance after your purchase. By following smart steps and utilizing Oyang’s tips, you can uncover hidden costs and secure the best value for your investment.

Ensuring the machine operates effectively and is stable

Evaluating its performance

Understanding the costs of operation

Confirming the manufacturer’s support availability

Key Takeaways

Decide what you want to make before you pick a machine. You should know how many bags you need each day. This helps you choose the right size and speed.

Make a budget that is fair and possible for you. Remember to include the price to buy the machine. Also add costs for installation, training, and fixing the machine later.

Think about the kind of bags you want to make. Each machine makes different styles. Pick one that matches what you need.

Find a brand you can trust, like Oyang. They should give good help after you buy and a strong warranty. This keeps your money safe.

Read what other customers say in reviews. Their stories can help you not make mistakes. You can use their advice to choose well.

Choosing the right machine for your needs

Assessing paper bag production requirements

When you start choosing the right machine, you need to look at your business goals and daily operations. Ask yourself, “How many paper bags do I want to make each day?” Your answer will help you figure out the size and speed of the machine you need. If you run a small shop, you might not need a huge machine. If you plan to supply bags to many stores, you’ll want something faster and more powerful.

Let’s break down what matters most:

Production Volume: Think about how many bags you want to produce every hour or day. If you expect your business to grow, pick a machine that can handle more bags in the future.

Bag Types: Different machines make different bags. Some machines create flat bottom bags that stand up well for retail displays. Others make gusseted bags with expandable sides, perfect for bulky items like food or gardening supplies. If you want bags with handles, you’ll need a machine that attaches handles for easy carrying.

Business Scale: Are you just starting out, or do you already have a steady stream of customers? Your business size will guide your choice. A small business may do fine with a basic model, while a larger company needs a machine with higher output.

Here’s a quick list of things that affect your production needs:

Simpler bag designs mean faster production.

High-quality raw materials help your machine run smoothly and avoid breakdowns.

Fully automated machines make more bags per hour than manual or semi-automatic ones.

Tip: Always think about your future needs. If you expect your business to grow, choosing the right machine now can save you money and trouble later.

Setting your budget range

Now, let’s talk about money. Setting a budget is a big part of choosing the right machine. You want to spend enough to get a reliable machine, but you don’t want to overspend and hurt your cash flow.

First, look at the price ranges for different machines. Here’s a table to help you compare:

| Type of Machine | Cost Range |

| Manual | $5,000 - $10,000 |

| Semi-Automatic | $5,000 - $20,000 |

| Mid-Range | $20,000 - $95,000 |

| Premium | $50,000 - $500,000 |

If you’re just starting, a manual or semi-automatic machine might fit your budget. If you want more speed and features, mid-range or premium machines offer better performance.

When you set your budget, think about more than just the sticker price. You need to consider:

The machine’s capabilities and how they match your business goals.

The total cost of ownership, including maintenance and repairs.

How much you’ll spend on training, spare parts, and energy.

Your financing plan. A smart plan helps you avoid financial stress and keeps your business running smoothly.

Note: Choosing the right bag making machine means looking at both your current needs and your future plans. If you plan for growth, you’ll avoid buying a machine that’s too small or too slow.

Choosing the right machine is not just about price. It’s about finding a machine that fits your production needs, your business size, and your budget. When you take time to assess your requirements and set a realistic budget, you’ll make a smart investment that helps your business grow.

Types of bag making machines and costs

Automatic vs. semi-automatic options

When you shop for a bag making machine, you will find two main types. These are automatic and semi-automatic machines. Each type works best for different businesses and budgets.

Automatic machines do almost everything by themselves. They need very little help from people. These machines can pack 50–100 kg every hour. You will need fewer workers, sometimes up to 80% less. If you want to make lots of bags quickly, automatic machines are a good choice.

Semi-automatic machines need more help from people. You or your team must place bags or add glue. This makes the process slower. You will need two or three people for each shift.

Here is a simple chart showing costs and what you get:

| Type of Machine | Description | Cost Range |

| Semi-Automatic | Needs manual work | $5,000 - $20,000 |

| Fully Automatic | Runs with minimal human help | $60,000 - $420,000 |

If you have a small shop, a semi-automatic or manual machine may be enough. Bigger businesses can save time and money with automatic machines.

Here is how business size matches with machine type:

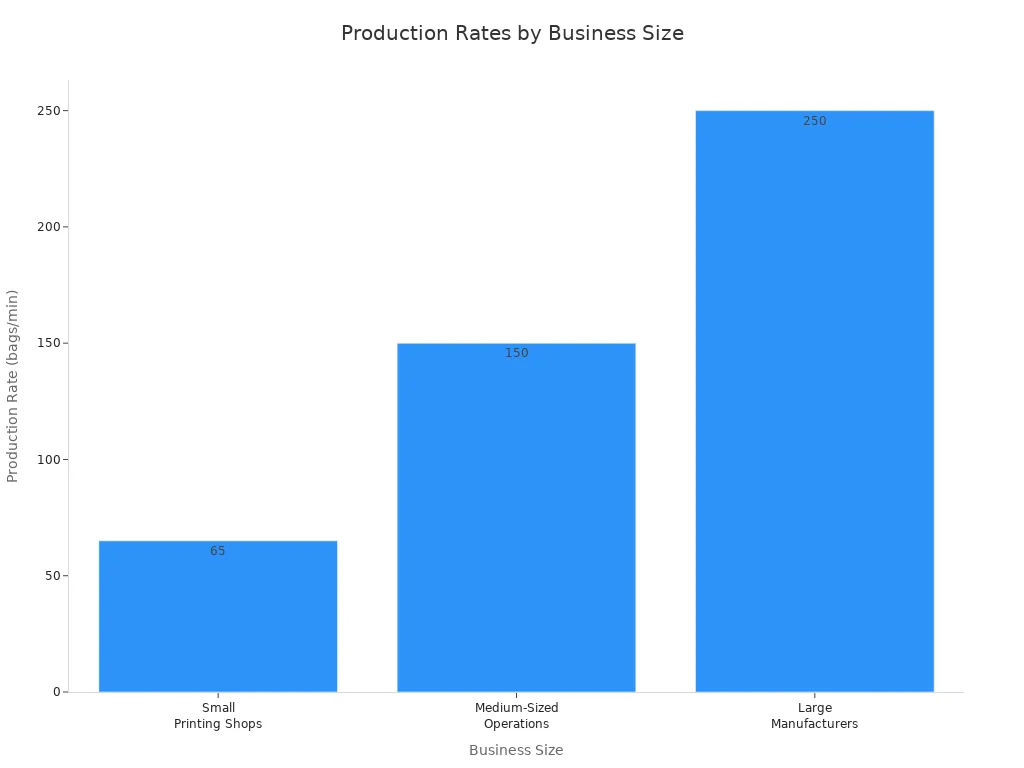

| Business Size | Machine Type | Production Rate (bags/min) | Additional Features |

| Small Printing Shops | Manual Paper Bag Machines | 50-80 | Low cost, minimal training required |

| Medium-Sized Operations | Automatic Paper Bag Machines | 120-180 | Automatic feeding, cutting, and gluing |

| Large Manufacturers | High-Speed Production Lines | 200-300 | Includes printing and handle making systems |

![Bar chart comparing paper bag production rates for small, medium, and large businesses]()

Comparing paper bag machinery features

Picking the right bag making machine is not just about price. You should look at the features that matter for your business. Here are some things to compare:

Automation level—How much does the machine do by itself?

Bag type—What kinds of bags can you make?

Production process—How does the machine build the bags?

Material compatibility—Can it use the paper you want?

Production speed—How many bags can it make each minute?

Extra features—Does it print, count, or add handles?

Budget—Does the machine give you good value?

Machines with more features cost more money. Fast, fully automatic machines use better parts and offer more choices. You pay extra for these options. If you want a strong bag making machine that lasts, it is smart to buy good quality and get strong support after you buy.

Oyang Paper Bag Making Machine advantages

If you choose an Oyang durable bag making machine, you get more than just a tool. Oyang is special because of its smart design and helpful features. Here is what makes Oyang stand out:

| Unique Features | Description |

| Advanced strategic thinking | Oyang plans every detail for top results. |

| High efficiency | Machines work fast and keep your business moving. |

| Innovation-driven designs | You get the latest technology in every machine. |

| Eco-friendly solutions | Oyang helps you protect the environment. |

| Strict quality control | Every durable bag making machine is built to last. |

| Investment in R&D | Oyang keeps improving with new ideas. |

Oyang’s durable bag making machine can make thousands of bags every hour. You can make many types of bags with different paper. The machines use smart controls, so you get good accuracy and less waste. Oyang also gives you strong technical help and after-sales service. This keeps your bag making machine working well for a long time.

If you want a durable bag making machine that is fast, eco-friendly, and simple to use, Oyang is a smart pick for any business that wants to grow in the paper bag industry.

Key features in paper bag machinery

Production speed and efficiency

You want your paper bag machine to work quickly. Most older machines make 30 to 40 bags each minute. Some newer machines can make up to 120 bags a minute. That is a big jump! If you pick a faster machine, you can fill more orders. Your business can grow faster. Fast machines also mean you need fewer workers. This saves you money on labor. Over time, a good machine saves you money. It needs less fixing and uses less energy and materials. You get more bags with less work. This means you earn more profit.

Tip: Faster machines help you spend less on repairs and energy. You can finish orders quicker.

Customization and flexibility

Every business wants different things. You may want bags in many sizes or with special handles. New machines let you change the size and style. You can add handles or auto-packing too. This helps you keep up with new trends and what customers want. The kraft paper market is getting bigger. More people want eco-friendly packaging. You need a machine that can make all kinds of bags to stay ahead.

| Customization Option | Description |

| Adjustable Bag Sizes | Lets you pick different bag sizes. |

| Handle Types | You can choose from many handle styles. |

| Inline QC | Checks bag quality during making. |

| Auto-Packing Units | Packs bags automatically for you. |

Energy savings and eco-friendly design

Saving energy helps your business and the planet. Many new machines use servo motors. These motors use up to 40% less energy. Smart controls and better heating systems also save power. Some machines have energy meters. You can see how much power you use and find ways to save more. Eco-friendly machines make less waste. They cut and fold paper very carefully. They can use recycled or biodegradable paper. This helps you follow rules about plastic and waste.

| Aspect | Description |

| Energy Consumption | New machines use up to 30% less power. |

| Operational Costs | Using less energy saves you money. |

| Environmental Impact | Less energy and waste helps the environment. |

Ease of use and maintenance

You want a machine that is easy to use. It should not break down often. Simple controls help your team learn fast. They make fewer mistakes. This means less waste and more good bags. Easy machines also cost less to train people. For maintenance, you should:

Clean the machine to get rid of dust and scraps.

Lubricate moving parts so they work well.

Check the conveyor to make sure it lines up.

Inspect electrical connections for safety.

Look at the cutting blades and change them if dull.

Test safety features like emergency stops.

Watch the temperature and humidity in your workspace.

Note: Easy machines help your team work faster and safer. Regular care keeps your machine working well.

Buying a bag making machine: What to check

Trusted brands and suppliers like Oyang

When you want to buy a bag making machine, pick a brand you trust. Oyang is known for smart designs and helpful support. Look for a supplier that gives machines with good adaptability and accuracy. The best brands make machines that use many kinds of paper and keep waste low. Here’s a table to help you compare important things:

| Criteria | Description |

| Machine Adaptability | Can use many paper types and eco-friendly paper. |

| Accuracy and Stability | Keeps colors, shapes, and glue neat for bags. |

| Scrap Rate | Makes less waste when making bags. |

| Key Functional Modules | Strong parts for feeding, glue, shaping, handles. |

| Maintainability | Easy to clean and fix for good use. |

| User-Friendliness | Simple controls and easy for workers to use. |

Make sure the supplier gives training and support. A good reputation and strong after-sales service help you use your bag making machine well.

Warranty and after-sales support

Warranty is important when you buy a bag making machine. You want to know your money is safe. Oyang and other top brands give a one-year warranty and lifelong service. You get help anytime, remote support, and spare parts. Here’s a quick look:

| Manufacturer | Warranty Period | After-Sales Support |

| Roll Fed V Sharp Bottom Paper Bag Making Machine | 1-Year Warranty | Lifelong Service, 24/7 support |

| Compostable 100% Recyclable Self Seal Recycled Kraft Cover Corrugated Paper Mailers Bag Making Machine | 1-Year Warranty | Lifetime maintenance, remote assistance, spare parts supply, on-site maintenance options |

Always ask about warranty before you buy a bag making machine. You want easy help if something breaks.

Customer reviews and testimonials

Before you buy a bag making machine, read what other buyers say. Reviews and testimonials show how the machine works for real people. You learn about reliability, support, and quality. Happy customers talk about easy controls, strong parts, and good service. If you see lots of good reviews, you know you are making a smart choice. You can ask suppliers for references or search for feedback online.

Tip: Real stories from buyers help you avoid mistakes and choose the best bag making machine for your needs.

Inspecting before purchase

You should check the bag making machine before you buy it. Here’s a simple checklist:

Check the age and usage. Ask how long the machine has run.

Look at the physical condition. Find loose bolts, worn blades, or dirt.

Review maintenance history. Ask for service records.

Do a test run. Watch the machine make bags and see if it works well.

If you follow these steps, you lower your risk when buying a bag making machine. You get a machine that works well and lasts longer.

Note: Careful checking helps you avoid expensive repairs and downtime after buying a bag making machine.

Additional costs in paper bag production

When you buy a paper bag making machine, you pay more than the price tag. There are extra costs you need to think about. These costs can surprise you if you do not plan ahead. If you want to save money, you should plan for these costs early.

Installation and training

Setting up your new machine takes time and money. You may need experts to install it. Your team will need to learn how to use it. Most suppliers charge for these services. Installation and training usually cost USD 50 to 100 each day. Ask your supplier about these costs before you buy. Good training helps your team work faster and safer. This protects your investment and helps the environment.

Installation fees: USD 50–100 per day

Training fees: USD 50–100 per day

Well-trained staff make fewer mistakes and keep your machine working well

Tip: Always add installation and training to your budget. This helps you avoid surprises and keeps your business running smoothly.

Spare parts and consumables

You will need spare parts and consumables while you use your machine. These include belts, blades, glue, and paper rolls. These costs keep coming as long as you use your machine. If you want to save money, you should watch these costs closely. Sometimes, cheaper machines use more spare parts. This can make your costs go up over time. Knowing the total cost helps you make smart choices and protect the environment.

Spare parts and consumables are costs that never stop

These costs change how much your machine really costs

Cheaper machines may need more parts and cost more later

Watching these costs helps you save money

Maintenance and repairs

Every machine needs care to work well. Regular maintenance keeps your machine running and stops big repair bills. You should clean your machine and check moving parts often. Replace anything that is worn out. If you skip maintenance, you may have expensive repairs and lose time. A good plan includes regular checks and quick fixes. This keeps your machine working and helps your business make less waste.

Here is a simple table to help you plan:

| Expense Type | How Often? | Why It Matters |

| Cleaning | Weekly | Stops breakdowns |

| Lubrication | Monthly | Keeps parts moving easily |

| Blade Replacement | As needed | Makes sure cuts are clean |

| Repairs | When needed | Stops long delays |

Note: Regular maintenance helps your machine save money and stops big surprises in your costs.

Maximizing value and avoiding mistakes

Negotiating price and terms

When you buy a bag making machine, you want the best deal. You can ask for discounts or extra services. Suppliers often give better terms if you show you know the market. Compare offers from different sellers. Ask about payment plans or free spare parts. You can also request training or longer warranty. If you focus on quality, you get more value for your investment. Always read the contract before you sign. Make sure the price includes everything you need.

Tip: Write down your needs and talk with the supplier. Clear communication helps you avoid surprises.

Avoiding hidden costs

Hidden costs can hurt your budget. You might see a low price, but extra fees add up. Watch out for shipping, installation, and taxes. Some bag making machine suppliers charge for after-sales support or spare parts. Ask for a full list of costs before you buy. Check if the price covers training and warranty. If you plan ahead, you save money and avoid stress.

| Cost Type | What to Check |

| Shipping | Is delivery included? |

| Installation | Are setup fees extra? |

| Spare Parts | Are they covered in the price? |

| Training | Is staff training included? |

| Warranty | How long does it last? |

Planning for future growth

You want your bag making machine to help your business grow. The market for bag making machines is getting bigger every year. More people want eco-friendly bags because of new rules on plastic. High-speed machines are popular in places like Germany, China, and India. E-commerce is making custom bags more important. If you choose a machine that can make many types of bags, you stay ahead. Automated machines help you work faster and meet more orders. Small businesses also buy semi-automatic machines to save money. Here are ways to plan for growth:

Pick a bag making machine that can make different bag styles.

Choose a machine with room to upgrade or add new features.

Watch market trends and adjust your production.

Invest in automation for higher efficiency.

Offer custom bags for online shops.

Learning from other buyers

You can learn a lot from people who already use a bag making machine. Read reviews and ask for feedback. Other buyers talk about price, quality, and service. They share tips about maintenance and spare parts. You find out which machines last longer and which suppliers give good support. If you listen to their stories, you avoid mistakes and make a smart investment.

Note: Join online forums or groups. You get advice and real stories from other business owners.

You’ve learned how to pick the right machine for your budget and needs. Here’s what you should do next:

List your production goals and budget.

Compare machine types and features.

Watch for hidden costs.

Ask for support and reviews.

Plan for successful paper bag production.

Ready to make a smart choice? Use Oyang’s expertise to research, compare, and invest in a machine that helps your business grow.

FAQ

How much does a paper bag making machine cost?

The cost of a bag making machine depends on its type and features. Manual machines start around $5,000. Automatic models can reach $500,000. Always check what’s included, like training or spare parts, before you buy.

Can I make different sizes and styles of bags with one machine?

Yes, many modern machines let you adjust settings for different bag sizes and styles. You can switch between flat, gusseted, or handled bags. This flexibility helps you meet changing customer needs.

How do I keep my machine running smoothly?

You should clean your machine often. Check moving parts and replace worn pieces. Follow the maintenance schedule from your supplier. Regular care helps your machine last longer and work better.

Why should I choose eco-friendly paper bag machines?

Eco-friendly machines help you go green. They use less energy and create less waste. You can make recyclable bags that customers love. This choice also helps your business follow new environmental rules.

What support does Oyang offer after I buy a machine?

Oyang gives you a one-year warranty and lifelong service. You get help with setup, training, and spare parts. Their team answers questions quickly, so you can keep your business running without worry.