Small businesses are looking for affordable paper bag making machines that do not cost much. Some good choices for affordable paper bag making include PowerPacker, SpeedMaster, and compact semi-automatic models. PowerPacker works with many kinds of paper and uses less energy, making it a great option for affordable paper bag making. SpeedMaster makes bags quickly and can create different styles, which is beneficial for businesses needing variety. Compact semi-automatic models are ideal for small shops with little space and are simple to use. Choosing the best machine for your budget and future plans in affordable paper bag making helps your business grow.

PowerPacker: Strong and works well every day

SpeedMaster: Makes bags fast and in many styles

Compact Semi-Automatic Models: Simple to use and good for the environment

Key Takeaways

Pick a paper bag machine that fits your budget and space. Mini and entry-level machines work well for small businesses with less money.

Think about semi-automatic machines for more choices. These machines let you make custom orders. They can handle busy times and help save money at first.

Automatic machines make bags much faster. They can make hundreds or thousands of bags every hour. This helps your business grow and fill big orders.

Eco-friendly machines bring in customers who care about the environment. These machines use recycled materials. They often have certifications that make your brand look better.

Keeping your machine in good shape is important. Plan regular checks and cleanings to stop breakdowns. This helps your machine work well for a long time.

Affordable paper bag making machines

Mini & Entry-Level Paper Bag Machine

Mini and entry-level paper bag machine models are good for new businesses. These machines are small and fit in tight spaces. They work well for companies that do not have much money. The cost for these machines is between $15,000 and $30,000. They have easy controls and only basic features. This makes them simple to use. Many small businesses pick these machines because they help save money and keep production steady.

Tip: Mini machines are best for businesses that want to spend less and have little space.

Semi-Automatic Paper Bag Machine

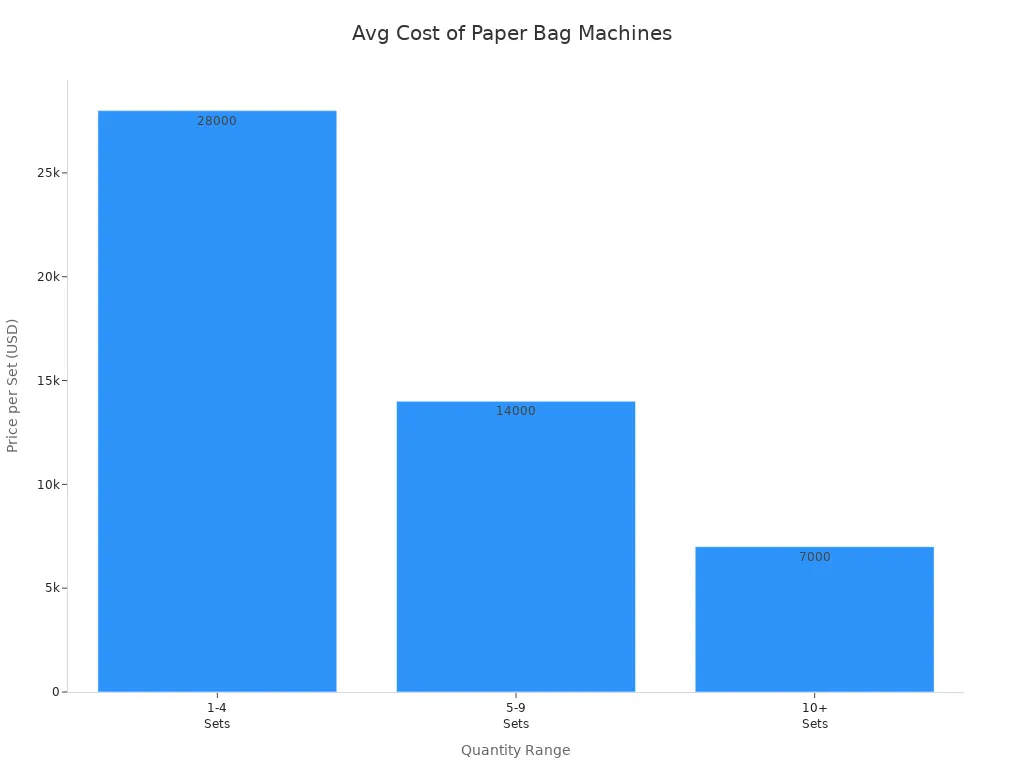

Semi-automatic paper bag machine models are popular with small businesses. These machines need some manual work. They can make different sizes and styles of bags. The price changes if you buy more sets.

| Quantity | Price per Set |

| 1-4 Sets | US$28,000.00 |

| 5-9 Sets | US$14,000.00 |

| 10+ Sets | US$7,000.00 |

Semi-automatic paper bag making machines help save money at first. They let you make custom orders and work for busy seasons. But they need more workers and the speed depends on who runs the machine.

| Advantages | Limitations |

| Lower starting costs | More workers needed |

| Can make small or medium batches | Speed depends on worker |

| Can handle special orders | N/A |

| Good for new businesses with little money | N/A |

| Works for busy or slow times | N/A |

![Bar chart comparing price per set of semi-automatic paper bag making machines by quantity range]()

Note: Semi-automatic machines are good for businesses that want cheap paper bag making and flexible work.

Automatic Paper Bag Machine

Automatic paper bag machine models are great for small businesses that want to make bags faster. There are semi-automatic and fully automatic types. Semi-automatic machines cost $5,000 to $20,000. Fully automatic machines cost $20,000 to $150,000.

| Type | Description | Price Range |

| Semi-Automatic | Needs some manual work | $5,000 - $20,000 |

| Fully Automatic | Needs little human help | $20,000 - $150,000 |

Automatic paper bag making machines work fast and save time. Semi-automatic machines make 400 to 800 bags each hour. Fully automatic machines make more than 1200 bags per hour. Small machines can make 800 to 1200 bags per hour. That means 6400 to 9600 bags in one work day. Semi-automatic systems can cut work time by about one-third and pay for themselves in 14 months.

Tip: Automatic machines help businesses grow and fill big orders with less work.

Handle Bag Machine

Handle bag machine models are good for businesses that want bags with handles. The price depends on the type and what the machine can do. Manual baggers cost $10,000 to $40,000. Mid-line roll-bagging machines cost $15,000 to $45,000. Fully automatic baggers with counters start at $20,000.

Manual baggers: $10,000 - $40,000

Mid-line roll-bagging: $15,000 - $45,000

Fully automatic baggers: $20,000 and up

Entry-level handle bag machines are often manual or semi-automatic. They are cheap and good for small jobs. Non woven bag making machines also help save money and let you make special bags. V-bottom machines are light and cost less, so they are good for businesses with small budgets.

Note: Handle bag machines need enough room to set up. Pick a machine that matches your business needs.

Eco-Friendly Paper Bag Machine

Eco-friendly paper bag machine models are becoming more popular with small businesses that want to make green products. These machines use recycled or biodegradable materials to make bags. The price starts at $10,000 and can go up to $138,800, depending on the type and features.

| Machine Type | Price Range (FOB) | Minimum Order |

| Paper Bag Machine | $10,000 - $138,800 | 1 Set |

| Roll Fed Square Bottom Fully Automatic Paper Bag Making Machine with Handle Bag | $10,000 - $138,800 | 1 Set |

| Eco-Friendly Chestnut Packaging French Bread Kraft Flat Square Bottom Paper Bag Sealing Making Producing Machine | $10,000 - $138,800 | 1 Set |

| Kraft Paper Bag Making Machine for Produce Handle Paper Bag | $10,000 - $78,800 | 1 Set |

Eco-friendly paper bag making machines often have certifications like CE, ISO 9001, and ISO 14001. These show the machines are safe, good quality, and follow environmental rules.

| Certification/Standard | Description |

| CE | Follows EU safety, health, and environment rules. |

| ISO 9001 | Uses standard steps for design and making. |

| ISO 14001 | Helps lower harm to the environment and saves energy. |

| Eco Compliance | Follows rules for safe chemical use. |

Tip: Eco-friendly machines help businesses get customers who care about the planet and want cheap paper bag making.

Which machines are best for startups, tight budgets, and small spaces?

New businesses and small companies often pick mini and entry-level paper bag machine models. These cost less and fit in small places. Semi-automatic machines are also good for small budgets and flexible work. Handle bag machines, especially entry-level and non woven types, help save money and let you make special bags. Eco-friendly machines help businesses grow in a green way.

Pick paper bag making machines based on your money, space, and work needs. Start with cheap paper bag making choices and get bigger as your business grows.

Machine overview for small businesses

Key Features & Specifications

Small businesses want machines that work well and are easy to use. Most machines have features that help make more bags faster. These features also make packaging simple. Many machines have CE certification. This means they are safe and good quality. Some machines use PLC controls. These controls help the machine work better and make it easy to run. The best machines can use kraft, recycled, or coated paper. Users can change bag sizes and styles. This helps meet what customers want.

| Feature | Description | Benefit |

| Production Capacity | Makes hundreds or thousands of bags each hour | Helps fill big orders and make more bags |

| Material Compatibility | Uses kraft, recycled, or coated paper | Lets you make different kinds of bags |

| Size Adjustability | Makes bags in many sizes and styles | Gives customers more choices |

| Automation Level | Fully automatic or semi-automatic choices | Saves money and works fast |

| Printing Capabilities | Prints logos and designs while making bags | Makes bags look special and unique |

Tip: Easy-to-use machines help workers learn fast and make fewer mistakes. Machines that save energy cost less to run and are good for the environment.

Price Range & Budget Considerations

Small businesses need to think about how much money they can spend. They also need to think about how the machine will help them later. Some machines cost less, and some cost more. Entry-level machines are cheaper. Automatic machines cost more. Most paper bag machines cost between $75,000 and $200,000. This price includes cutting and making bags. Some businesses save money by renting machines or buying used ones. Others get deals by buying lots of accessories at once or by talking about lease prices.

| Expense Component | Estimated Cost | Notes |

| Paper Bag Machinery | $75,000 - $200,000 | Includes new or used machines and repairs |

Renting or buying used machines helps save money.

Buying accessories in bulk can give discounts.

Getting better machines as your business grows keeps costs low.

Production Capacity

Machines make different numbers of bags each minute. Automatic machines make 100 to 1000 bags every minute. Semi-automatic machines make 200 to 280 bags each minute. Entry-level machines make fewer bags but still work well. Automated machines help small businesses grow fast and keep up with changes.

| Machine Type | Production Capacity (bags per minute) |

| Automatic | 100 to 1000+ |

| Semi-Automatic | 200 to 280 |

| Entry-Level | Lower output, steady production |

Automation helps save money on workers and lowers mistakes. It also helps make more bags, so businesses can grow. Small businesses that pick machines with high capacity can fill more orders and get bigger faster.

Note: Machines that make lots of bags help small businesses keep up with orders and plan for the future.

Comparing paper bag machine types

V Bottom vs. Square Bottom

V bottom and square bottom machines help small businesses make bags. They work in different ways. V bottom machines use less material. This keeps costs low. They run fast and are good for light products like snacks or bread. Square bottom machines need more material to stay strong. This makes them cost more. These machines are best for shopping bags and food packaging.

| Feature/Aspect | V Bottom Paper Bag Machine | Square Bottom Paper Bag Machine |

| Production Process | Fully automatic, includes unwinding, gluing, tube forming, cutting, and bottom forming. | Fully automatic, includes handle making, gluing, tube forming, cutting, and bottom forming. |

| Efficiency | More convenient, efficient, and stable for eco-friendly bags. | Intelligent and easy to operate, great for mass production. |

| Applications | Snack food bags, bread bags, specialty drug packaging. | Shopping and delivery bags, with or without handles. |

Handle vs. Standard Bag Machines

Handle bag machines give small businesses more choices. Users can change bag sizes for different products. These machines are cheaper and need less money to buy. Handle bag machines help make more bags and work for many needs. Standard bag machines, especially manual ones, are good for new businesses. They cost less and can handle special items. Semi-automatic machines mix speed and hand work. They help small businesses during busy times.

Mini vs. Full-Scale Machines

Mini machines fit in small places and cost less. They make simple bags and help new businesses start safely. Full-scale machines make more bags and have automatic features. These machines need more space and money. They help businesses grow bigger.

Pros & Cons

Small businesses pick affordable machines because they are easy to fix and learn. The table below shows the good and bad sides:

| Advantages | Disadvantages |

| Affordable Entry Point | Manual Labor Requirements |

| Simpler Maintenance | Limited Upgrades |

| Less Operator Training | Lower Output |

Tip: Small businesses should pick machines that match their money, space, and work needs. The right machine helps them grow and save money.

Choosing your paper bag machine

Assessing Production Needs

Small businesses need to know their goals first. They should decide how many bags to make each day. They also need to know what bag types customers want. Here are some steps that can help:

Think about how much money you will spend and earn.

Check what you need to run the machine and pay workers.

Study the market and learn what people want.

Find out when you will start making a profit.

Make plans for selling bags in other countries.

A fully automatic machine makes more bags. It needs skilled workers and enough money for supplies. Owners must think about fixing and keeping the machine working. Marketing helps find out if people want eco-friendly bags or cheaper ones. Planning for growth helps the machine fit future needs.

Tip: The right machine helps a business get more customers and grow.

Budget Planning

Budget planning is needed before buying a machine. Owners should count all costs, not just the machine price. This means thinking about supplies, workers, rent, and ads. Checking the budget often helps owners change plans if needed.

| Machine Type | Price Range (USD) |

| Semi-automatic | $20,000 - $60,000 |

| Automatic | $50,000 - $500,000 |

| Mid-Range | $20,000 - $100,000 |

| High-Speed | $100,000 - $300,000 |

| Specialty Models | $80,000 - $100,000 |

| Basic Models | Starting from $80,000 |

A small semi-automatic setup may need $50,000. Big automatic setups can cost over $500,000. Most new businesses spend $122,000 to $308,000. Owners should plan for every cost to keep things running well.

Space & Setup Requirements

Setting up machines needs good planning. Owners must pick a place that is easy to reach and has the right rules. The space should have room for supplies, making bags, finished bags, offices, and loading. Power, water, and waste systems must be ready. Putting machines and tables in smart spots helps workers move safely and fast.

Good locations help with power and water.

Space should fit machines, storage, and packing.

Smart layouts save time and keep workers safe.

Note: A smart setup helps machines work better and makes daily jobs easier.

Eco-Friendly Options

Eco-friendly machines bring in customers who care about nature. These machines use recycled or biodegradable materials. They often save energy and have green features. Owners should pick machines with safety and eco certificates. Choosing eco-friendly machines helps businesses stand out and follow new rules.

Eco-friendly machines help small businesses look good and keep the planet clean.

Practical buying tips for small businesses

Maintenance & Ease of Use

Taking care of machines helps small businesses save money. Owners should check their reliable paper bag machine every few months. They need to use the right tools when changing parts. Cleaning and adding oil to moving parts keeps things working well. Safety is important, so workers must follow safety steps when cleaning or fixing. Compact semi-automatic models make these jobs easier. They have simple controls and fewer parts.

Tip: Regular care means fewer problems and lower costs later.

Supplier Support & Warranty

Picking a good supplier helps a lot. Good suppliers give strong support and clear warranties. The table below shows what many suppliers offer for affordable machines:

| Feature | Details |

| Warranty | One-year warranty on all machines |

| Free Replacement Parts | Available if the machine breaks down within the warranty period |

| Technical Support | Lifetime technical support for customers |

| Maintenance Checks | Regular inspections every 6 months to ensure optimal performance |

| Replacement of Worn Parts | All worn-out or damaged parts replaced for free within the warranty period |

A supplier who answers questions quickly and helps with repairs gives peace of mind. This support lets small businesses focus on making eco-friendly packaging and growing their business.

Scalability & Future Growth

Planning ahead helps a business get stronger. Owners should make a business plan with their mission, vision, and market goals. They can find money from savings, loans, or investors. Picking the right machines and building a steady supply chain makes growing easier. Marketing helps find new customers who want eco-friendly bags.

Small businesses that plan for growth and care about the planet can stand out in the market.

Small businesses have many affordable paper bag making machines to choose from. Owners should pick a machine that fits their needs and budget. They can compare features, ask suppliers questions, and plan for future growth. A smart next step is to contact suppliers or request a demo. This helps them find the best fit for their business.

FAQ

What is the best paper bag machine for a small shop?

A mini or entry-level paper bag machine works best for small shops. These machines fit in tight spaces and cost less. Owners like them because they are easy to use and maintain.

How much space does a paper bag machine need?

Most small machines need about 100 to 200 square feet. Owners should plan for extra room for supplies and finished bags. A smart layout helps workers move safely and quickly.

Can these machines use recycled paper?

Yes, many affordable paper bag machines work with recycled paper. Owners can choose eco-friendly models for better results. Customers like bags made from recycled materials.

How often should owners service their machines?

Owners should check and clean machines every month. Regular oiling and part checks keep machines running well. Good care helps avoid breakdowns and saves money.