You can see many different paper bag making machine prices today. Some semi-automatic machines cost about $5,000. High-speed and custom machines can cost $500,000 or even more. The paper bag making machine price changes based on the kind of machine you pick. It also depends on how automatic the machine is. The number of bags you want to make each day matters too. Flat paper bag machines are cheaper. They have a simple design. Square bottom machines are stronger and faster. You will pay more for these features. Look at the table below to see how prices change for each machine type.

| Type of Machine | Cost Range |

| Semi-Automatic | $5,000 - $20,000 |

| Fully Automatic | $20,000 - $150,000 |

| High-Speed | $50,000 - $300,000 |

| Customized | $100,000 - $500,000+ |

Picking the right machine helps you spend your money wisely. It also helps you reach your business goals.

Key Takeaways

Paper bag making machines have different prices. The price depends on the type and features. Basic machines cost between $5,000 and $20,000. Fast and special machines can cost over $500,000.

Think about how many bags you need to make. Machines that make more bags each day usually cost more. Make sure your budget matches the machine’s capacity. This helps you work better.

How much the machine does by itself changes the price. Fully automatic machines cost more. They save on workers and make bags faster. Pick a machine that fits your business size and goals.

Look at all the costs of owning a machine. This includes fixing it and paying for energy. A cheaper machine might cost more later. Think about every cost before you buy.

Check out different sellers and talk about the price. Comparing choices helps you find the best deal. This makes sure you get the right machine for your business.

Paper Bag Making Machine Price Overview

There are many prices for paper bag making machines. You can pick simple machines or fast ones. Each machine type costs a different amount. Your choice depends on your business size. It also depends on how many bags you want to make. Your budget matters too. The table below shows the cost for each machine type.

Entry-Level Paper Bag Machine Cost

Entry-level machines are good for small businesses. They are also good for people who are new. These machines are usually semi-automatic. You get basic bag shapes. There are not many extra features. Entry-level machines cost less than advanced ones. You pay between $7,000 and $20,000 for a new entry-level machine. In RMB, the price is 50,000 to 150,000. These machines make bags slower. You make fewer bags each hour. You spend less money but get fewer features.

| Feature | Description |

| Type | Semi-automatic |

| Suitable for | Small businesses or beginners in production |

| Price Range | 50,000 to 150,000 RMB |

| Production Speed | Generally lower compared to advanced models |

| Functionality | Basic bag shapes, limited features |

If you want to spend less, entry-level machines help you save money. You can buy a better machine later when your business gets bigger.

Mid-Range Paper Bag Making Machine Price

Mid-range machines have more features. They work faster than entry-level machines. You can find semi-automatic and fully automatic machines here. These machines cost more because they need less help from people. You pay between $20,000 and $100,000 for a mid-range machine. Some popular models are JB Machinery SwiftBag Series ($50,000 - $70,000) and Nessco NPBM-190 ($60,000 - $80,000).

Faster machines cost more because they make more bags.

Fully automatic machines cost more than semi-automatic ones. You save on labor and get better results.

Semi-automatic machines are cheaper. They are good for small businesses.

If you want to grow your business, mid-range machines give you a good mix of price and features.

High-Speed and Fully Automatic Machine Cost

High-speed and fully automatic machines work the best. They use new technology. You get robotics, smart sorting, and printing that works by itself. These machines cost a lot more. You pay between $100,000 and $300,000 for a high-speed machine. Some models, like Ruian XH-330 Fully Automatic, cost $115,000 to $150,000. Nova Machinery EcoBag Master costs $110,000 to $130,000.

| Advanced Features | Impact on Price |

| Robotics | Higher capital equipment costs due to advanced tech |

| Advanced control systems | Long-term savings through increased efficiency |

| Precision engineering | Reduced waste and improved production efficiency |

| Integrated bag inspection | Supports sustainability goals |

| Automated printing | Enhances production efficiency |

| Smart sorting | Reduces manual intervention |

| Capabilities for diverse materials | Justifies higher initial investment |

| Energy-efficient drives | Aligns with sustainability mandates |

| Low-emission pneumatic systems | Reduces operational costs |

| Modular components for upgrades | Minimizes need for full-scale replacements |

You spend more money at first. You get faster speed, less waste, and more bag choices. If you want a big factory, high-speed machines help you reach your goals.

Used and Specialty Paper Bag Machine Price

You can buy used machines or special models. Used machines cost less than new ones. The price depends on how old the machine is. It also depends on how well it works. Newer machines that are cared for cost more. Older machines cost less because they may break or need repairs. Special machines, like square bottom or V-bottom, cost $80,000 to $100,000. Basic models start at $80,000.

| Machine Type | Price Range (USD) |

| New Paper Bag Making Machine | 200,000 - 250,000 |

| Used Paper Bag Making Machine | Less than new machines |

| Specialty Models (Square/V-bottom) | 80,000 - 100,000 |

| Basic Models | Starting from 80,000 |

Used machines sell for more if they are newer. Machines with new technology and good care cost more. Old machines lose value because they may break or need hard-to-find parts.

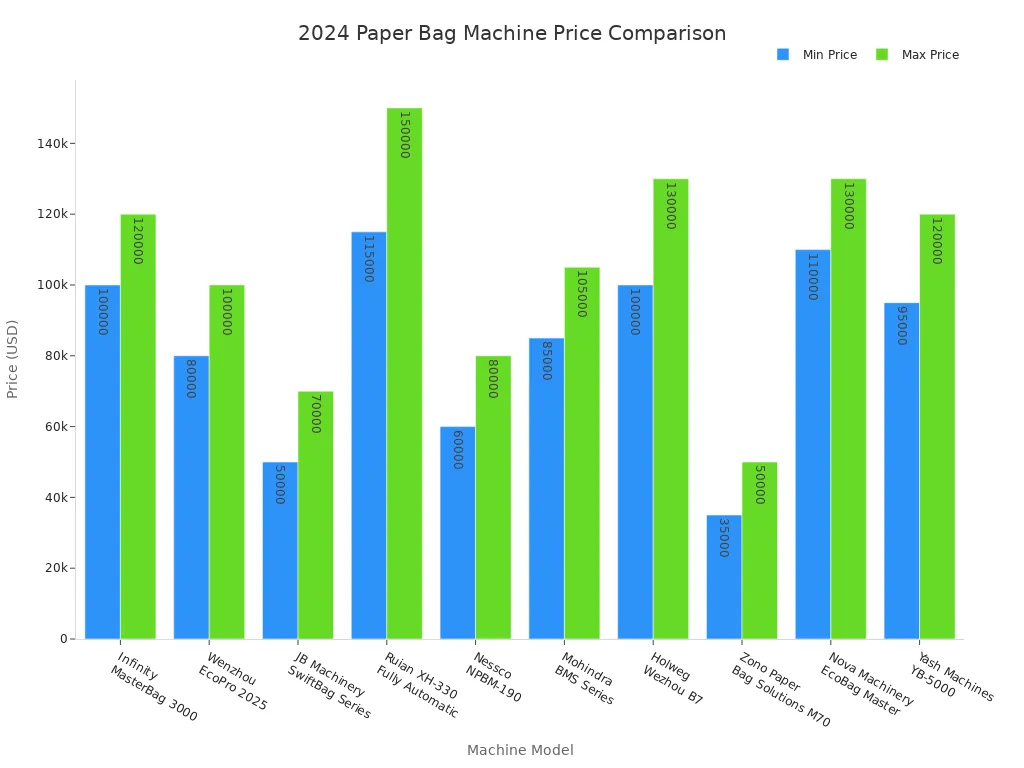

Price Comparison Table for Popular Models

You can look at the table below to compare machine prices. This helps you pick the right machine for your money and needs.

| Machine Model | Approximate Price Range |

| Infinity MasterBag 3000 | $100,000 - $120,000 |

| Wenzhou EcoPro 2025 | $80,000 - $100,000 |

| JB Machinery SwiftBag Series | $50,000 - $70,000 |

| Ruian XH-330 Fully Automatic | $115,000 - $150,000 |

| Nessco NPBM-190 | $60,000 - $80,000 |

| Mohindra BMS Series | $85,000 - $105,000 |

| Holweg Wezhou B7 | $100,000 - $130,000 |

| Zono Paper Bag Solutions M70 | $35,000 - $50,000 |

| Nova Machinery EcoBag Master | $110,000 - $130,000 |

| Yash Machines YB-5000 | $95,000 - $120,000 |

![Bar chart comparing minimum and maximum prices of paper bag making machines in 2024]()

Tip: Always check the machine types before you buy. Compare the price, features, and speed. This helps you choose the best machine for your business.

Paper bag making machine prices change a lot. Entry-level machines cost less but have fewer features. High-speed and automatic machines cost more but work faster and have more options. Used and special machines give you more choices for your budget. Always pick a machine that fits your business and budget.

Factors Affecting Paper Bag Making Machine Price

Production Capacity

Production capacity is very important for price. Machines that make more bags cost more money. If you want a machine that makes many bags, you will pay more. Machines that make over 5,000 bags each day cost more than 200,000 yuan. This is because bigger machines need stronger parts and better systems. Look at the table to see how making more bags changes the price:

| Production Capacity Range | Price Range |

| 30 to 60 bags per minute | Budget models |

| 80 to 150 bags per minute | Mid-range models ($30,000 - $100,000) |

| 200 to 400 bags per minute | Premium models ($100,000 - $500,000) |

If you want your business to grow, match your budget to the machine size. A small shop can use a machine that makes fewer bags. Big factories need machines that make lots of bags, but these cost more.

Automation Level

How automatic the machine is also changes the price. You can pick manual, semi-automatic, or fully automatic machines. Semi-automatic machines cost between $20,000 and $60,000. Fully automatic machines cost from $50,000 to $500,000. If you want to save on workers and make bags faster, pick a machine with more automation. Fully automatic machines help you make more bags with less work, but they cost more.

| Type of Machine | Price Range |

| Semi-Automatic | $20,000 - $60,000 |

| Fully Automatic | $50,000 - $500,000 |

Features and Customization

Extra features and custom choices make the machine cost more. If you want high-speed, special bag sizes, eco-friendly bags, or automatic bottom folding, you pay extra. These features help your bags stand out. The table shows how features change the price:

| Feature | Impact on Price |

| High-Speed Production | Increases efficiency |

| Custom Bag Sizes | Allows for branding |

| Eco-Friendly Bags | Appeals to eco-conscious consumers |

| Automatic Bottom Folding | Enhances production speed |

| Durable Paper Handling | Reduces material waste |

If you want to print logos or add special handles, you pay more. Some businesses, like medicine companies, need special cutting and clean features. Stores want custom handles and printing for their brand. These choices change the price and help you meet what your customers want.

Tip: Custom features cost more at first, but they help you get more customers and earn your money back later.

Brand and Location

The brand and where you buy the machine also change the price. Famous brands like Newlong, Holweg Weber, and Windmoller & Holscher cost more. These brands use better parts and have more features. Sunhope is cheaper, but you may not get the same quality. Buying from a local seller can save you money on shipping and service. If you buy from another country, you pay more for shipping and help.

Newlong: Good technology, higher price.

Holweg Weber: Saves energy, costs more.

Windmoller & Holscher: Modern, saves money, but is expensive.

Sunhope: Cheaper, good for new businesses.

When you choose a machine, think about your money, the brand, and where you buy it. These things change the total price and what you get for your money.

How to Choose the Right Paper Bag Machine

Assessing Your Needs and Budget

You should pick a bag making machine that fits your business. First, think about what your business needs and how much money you have. Here are some easy steps to help you:

Choose if you want a fully automatic, semi-automatic, or manual machine. Your business size will help you decide.

Think about how many workers you want to use. Automatic machines need fewer workers and save money.

Write down the types of machines that work for your business. Think about the bag size and what they are made of.

Look at your business type. Food, retail, and packaging companies need different machine features.

Guess how many bags you need each day. Pick a machine that can make that many bags.

Think about the bag sizes and styles you want to sell. Choose a machine that can make those bags.

Make a budget. Do not spend money on things you do not need.

Tip: If you want your business to grow, pick a machine that can make more bags later.

Evaluating Total Cost of Ownership

You should not only look at the price to buy the machine. The total cost has many parts. The table below shows what you should think about:

| Component | Description |

| Maintenance | Money for fixing and taking care of your machine. |

| Energy Consumption | Money for electricity and other power to run the machine. |

| Consumables | Things like film and spare parts you need to keep making bags. |

You also need to think about how much it costs to use the machine. This means energy, workers, fixing, and repairs. These costs can get big over time. Fully automatic machines save money on workers but may cost more to fix.

Note: Always look at the long-term cost before you buy a machine.

Sourcing and Negotiation Tips

Finding a good seller helps you get the best machine for your money. Try these tips:

Look at different sellers. Check their websites and compare machines.

Talk to salespeople. Ask about price, features, and help after you buy.

You can use a helper if you need help buying.

Be nice and sure when you talk about price. Tell them if you worry about cost.

Ask for free shipping or training for your machine.

Check what most machines cost. This helps you know a fair price.

Ask for a discount or special deal. Many sellers give deals to new buyers.

Tip: Good talking can help you pay less and get more for your money.

Picking the right bag making machine means you match your needs, money, and business goals. You should look at all costs and compare sellers. If you plan well, you can find a machine that helps your business get bigger.

You can find many prices for a paper bag machine. Some entry-level machines cost less. High-speed machines cost much more. Think about what you need before you buy. Check how fast the machine works. Make sure it uses the right materials. Pick a machine that fits your budget and goals.

Look at the quality and how automatic the machine is.

See if you can change features to fit your needs.

Compare prices and check for good support after you buy.

To pick the best machine, do these things:

Learn about different prices and machine types.

Think about how much you will spend over time.

Choose a machine that saves energy.

Plan how you will take care of the machine.

You make a smart choice when you look at all options. Focus on price, quality, and what your business needs.

FAQ

What is the lifespan of a paper bag machine?

A paper bag machine can last 8 to 12 years. You need to take care of it often. Good care stops problems and keeps it working well.

How much space do you need for installation?

Most machines need 300 to 500 square feet. You should have space to use and fix the machine. Make sure people can move safely around it.

Can you use recycled paper with these machines?

Most machines can use recycled paper. Always check the machine details before buying. Some machines work best with certain paper types.

What support do manufacturers offer after purchase?

Manufacturers give training and spare parts. They also help with technical problems. Ask about warranty and service before you buy a machine.