A new time for packaging has started. People are moving away from plastic. They now choose eco-friendly options. The recycled paper bags market is growing fast. It will go from $3.11 billion in 2024 to $5.40 billion by 2034. This shows people want more sustainable choices. Many places are helping this change:

Europe wants more kraft papers.

North America is growing because people know about plastic pollution.

India saw a 39% rise in paper-based packaging imports.

Entrepreneurs, business leaders, and people who care about the planet feel inspired by these stories. Paper bag manufacturers show that being green and being successful can happen together.

Key Takeaways

The paper bag market is growing fast. It may reach $5.40 billion by 2034. This change shows people want eco-friendly packaging.

Sustainability is very important for success. Manufacturers use recycled materials and biodegradable choices. This helps meet what customers want and follows environmental rules.

Entrepreneurs like Andrew Mupuya show that hard work matters. Innovation also helps people succeed in eco-friendly packaging. Their stories inspire others to follow their dreams.

Companies that face challenges, like Urja Packaging during the pandemic, can find new chances. They can grow a lot. This shows that being strong and flexible is good.

Listening to customers and making quality products is important. It helps build brand loyalty. Happy customers come back. This helps businesses do well in a tough market.

Paper Bag Manufacturers and Market Growth

Industry Trends and Sustainability

The paper packaging industry is changing a lot. In the last ten years, the global paper bags market grew fast. It was worth USD 7.05 billion in 2024. By 2032, it may reach USD 11.07 billion. This happened for a few reasons:

More people want packaging that is good for the earth.

Governments have made rules against plastic.

People care more about protecting nature.

Now, manufacturers use recycled kraft paper, agro-waste fibers, and biodegradable coatings. This helps make a circular economy. In this system, materials get used again or break down on their own.

Some trends are shaping the industry:

| Trend | Description |

| Biodegradable and Compostable | Companies make paper bags that break down fast. This means less trash in landfills. |

| Recycled and FSC-Certified | Many use recycled paper and certified materials. This helps save forests. |

| Reduction of Plastic Coatings | Producers use less plastic coatings. This makes bags easier to recycle. |

Manufacturers also make bags that are stronger and can resist water. They offer special designs for brands. These new ideas help businesses be different and give customers what they want.

Demand for Eco-Friendly Packaging

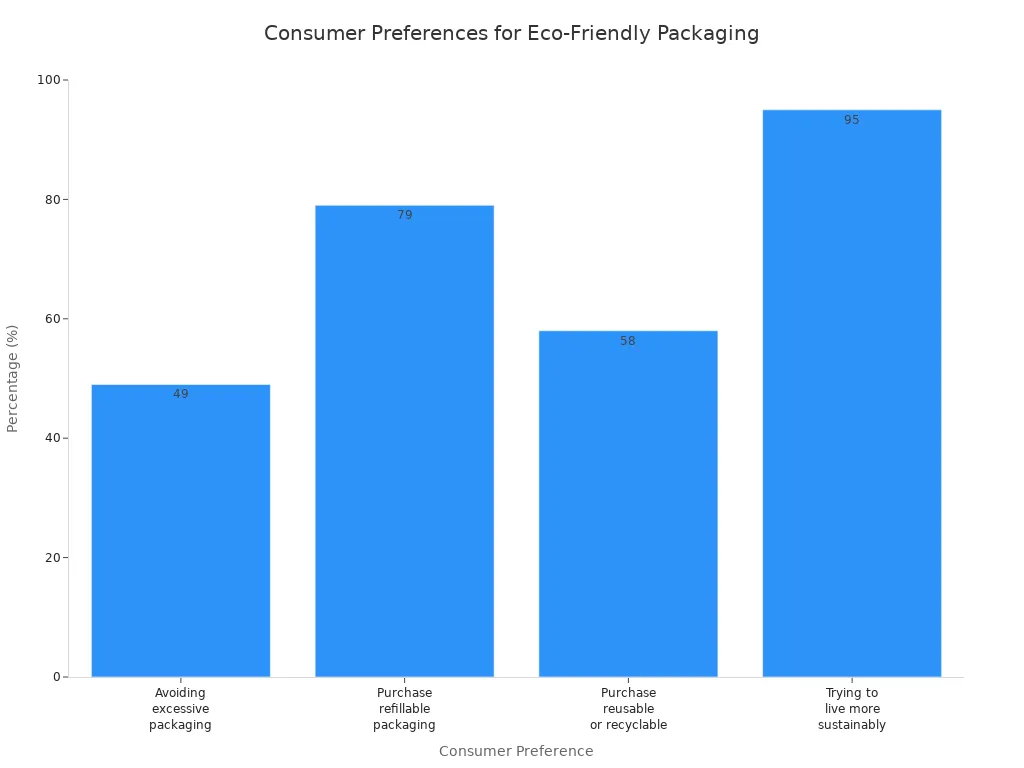

People all over want to help the planet. A new survey found:

| Statistic | Percentage |

| Consumers avoiding excessive packaging | 49% |

| Likelihood to purchase based on refillable packaging | 79% |

| Likelihood to purchase products with reusable or recyclable packaging | 58% |

| Consumers trying to live more sustainably | 95% |

![Bar chart comparing consumer preferences for eco-friendly packaging options]()

Paper packaging has many good points:

It can break down and turn into compost.

It comes from things that can grow again.

It is easy to recycle and uses less energy than plastic.

Paper bag manufacturers make products that fit what people want. More countries are banning plastic bags. So, more people want paper packaging. This change pushes companies to try new things and lead the way to a greener world.

Success Story: Andrew Mupuya’s Paper Bag Business

Entrepreneurial Beginnings

Andrew Mupuya had a big dream. He wanted to help the planet. He saw people in Uganda needed eco-friendly packaging. He did not have money to start his business. So, he picked up used plastic bottles. He sold them to a recycling plant. This gave him some money to begin. Andrew needed to learn how to make paper bags. He spent time learning new skills. Many people did not believe in him. Some teachers and friends said he should focus on school. They thought he would fail. Andrew did not give up. He kept believing in his idea.

Overcoming Challenges

Andrew faced many problems. He did not get much help. He learned new things and made his products better. He listened to advice and changed his work. He kept trying even when it was hard. Andrew’s story shows hard work pays off. Many paper bag manufacturers have tough times too. Andrew’s journey proves anyone can succeed.

Impact and Recognition

Andrew’s company is called Youth Entrepreneurial Link Investments (YELI). It gives jobs to more than 50 people. The business makes paper bags that help cut down plastic waste. YELI pays fair wages and helps local families. Andrew has won many awards:

| Year | Award Name | Prize Amount | Description |

| 2011 | Business Plan Writing Competition | $1,000 | He won out of 300 people and bought furniture for his company. |

| 2012 | African Leadership Young Entrepreneurs Award | $30,000 | He was the winner among 270 people and grew his business. |

| 2013 | Social Entrepreneurship Award | N/A | He was one of four winners in Europe, beating finalists from Norway, Sweden, and the USA. |

Andrew also won the Anzisha Prize in 2012. He was in Forbes Africa 30 Under 30. His story inspires other paper bag makers and young people to chase their dreams.

Success Story: Urja Packaging’s Resilience

Rebuilding the Paper Bag Business

Urja Packaging began as a small family business in India. One day, a fire burned down their workshop. The owners did not quit. They built the factory again from nothing. Every family member helped out. They cleaned up the mess. They fixed broken things. They bought new machines. Their hard work made a big difference. Urja Packaging came back stronger than before. Many people in their town cheered for them. The company became a sign of hope for other paper bag makers.

Innovation During the Pandemic

The COVID-19 pandemic made things tough. Many businesses had to close. Urja Packaging saw a chance to grow. They made new paper bags for food and medicine delivery. The team used safer materials. They made the factory cleaner. They taught workers to follow health rules. Urja Packaging started selling bags online. This helped them find new customers. The company proved that new ideas can help you grow, even when times are hard.

Urja Packaging’s story shows that hard times can bring new ideas. They turned problems into chances to get better.

Tenfold Growth and Lessons Learned

Urja Packaging grew ten times bigger in a few years. The company hired more people. They bought better machines. They sold bags in new cities and sent them to other countries. They focused on making good products and helping customers. The owners learned that working together helps you win. They learned that listening to customers helps you grow. Urja Packaging’s story inspires others to keep trying, no matter what happens.

| Lesson Learned | Impact on Growth |

| Teamwork | Faster recovery |

| Innovation | New markets opened |

| Customer feedback | Better products |

| Resilience | Long-term growth |

Leading Paper Bag Manufacturers Worldwide

Duro Bag’s Legacy and Stability

Duro Bag is a top company in paper bags. They are known for making good products. Duro Bag uses materials that are safe for nature. Their bags can be recycled. They care about the planet more than some other companies. Duro Bag makes many kinds of bags. Some are for food, and some break down in compost. The company keeps growing because they try new things and help the environment.

| Strategy | Description |

| Diverse Product Offerings | Duro Bag makes many bags for different uses. |

| Commitment to Sustainability | They use recycled materials and try to protect nature. |

| Customization Options | Customers pick the size, color, and look of their bags. |

| Advanced Technology and Innovation | Duro Bag uses new machines and skilled workers to do well. |

| Global Reach and Distribution | The company sells bags to people all over the world. |

| Rigorous Quality Control | Duro Bag checks every bag to make sure it is good. |

| Focus on Customer Service | The company helps customers from start to finish. |

American Paper Bag’s Technological Innovation

American Paper Bag is a leader because they use new technology. Their machines print designs fast and let people order custom bags. The system prints on both sides, so customers have more choices. They use paper with 40% post-consumer content. Bags have QR codes to help with recycling. In three years, automation grew by 35%. This makes making bags faster and better.

| Advancement Type | Description |

| Modern Manufacturing Equipment | Machines make custom bags quickly. |

| Smart Manufacturing Integration | Printing on both sides gives more choices. |

| Sustainability Initiatives | Bags use recycled paper and have QR codes for recycling. |

ALB-GOLD’s Sustainable Packaging Shift

ALB-GOLD changed its packaging to help the earth. They use Billerud Axello®ZAP paper now. This paper saves 65% CO2 compared to plastic. Customers and stores like the new bags. The bags can be recycled, which people want. ALB-GOLD’s new packaging made their brand look better. It helped them stand out from others.

The new bags save 65% CO2 compared to plastic.

Customers and stores gave good feedback.

The bags can be recycled and meet what people want.

Customer-Centric Innovations in the UK

British paper bag makers listen to what people want. Ocado stopped using plastic bags and switched to paper. People were happy about this change. Social media had lots of praise for Ocado. Customers want products that help the planet. Companies make better bags because of this. Rules also make companies try new ideas and protect nature.

UK customers liked Ocado’s switch to paper bags.

Social media showed lots of support for eco-friendly choices.

Companies make new bags because customers and rules ask for it.

Key Factors Behind Every Success Story

Innovation and Adaptability

Paper bag makers come up with new ideas. They change how they work to fit what buyers want. Companies use recycled stuff and biodegradable choices. This helps them stay ahead of others. American Paper Bag shows how new ideas can change a business. They use smart machines and let people pick their own designs. These changes make customers happy and help the earth.

Manufacturers buy better machines. These machines make bags faster and use less power. Zenbo’s machines make strong bags and help nature. More people want eco-friendly packaging, so companies keep improving. Businesses that follow new rules and trends grow quicker. They change how they get supplies and use better materials. They also do the right thing to earn trust.

New ideas give companies a big boost. Being able to change helps them solve problems and win.

More people want products that are good for the planet.

Online shopping means more need for green packaging.

Companies change to meet new laws and what customers want.

Sustainability as a Core Value

Paper bag makers care about the earth. They pick fibers like hemp and bamboo. Making bags close to home cuts down on pollution. Eco-design makes bags work better. Using computers helps track every step in making bags.

They use cellulose from forests that are taken care of.

They get certifications like FSC to show they protect nature.

When they cut down a tree, they plant another one.

Manufacturers use energy that comes from the sun or wind. They save water and use fewer chemicals. These steps help the planet and keep products safe. Many companies try to make money and be green at the same time. They make their work better and use top materials. Machines that save energy help them spend less and protect the future.

| Strategy | Impact on Profitability and Sustainability |

| Making work better | Cuts costs and helps work faster, so profits go up. |

| Using top materials | Keeps products good and controls spending. |

| Making lots at once | Lowers cost for each bag, so prices can be better. |

| Customizing and branding | Gets more customers and lets them charge more. |

| Energy-saving machines | Cuts costs and helps the planet. |

| Using new technology | Makes work faster and bags better. |

Customer Satisfaction and Brand Loyalty

Top paper bag makers listen to their buyers. They check how happy people are and make products better. Companies look at how many orders are right and how many bags have problems. They ask for feedback with surveys. Money numbers help them grow and give good service.

| Metric | Description |

| Customer Satisfaction Score | Shows how happy buyers are and helps make things better. |

| Order Accuracy Rates | Checks if orders are right, which builds trust. |

| Defect Rates | Counts bad bags, which helps keep quality and trust. |

| Customer Surveys | Gets feedback often to see if products and service are good. |

| Financial Metrics | Looks at money and happiness to keep the business strong. |

| Marketing and Pricing Strategy | Changes plans based on feedback to keep up green efforts. |

People like brands with cool bags and strong designs. Tough bags make buyers come back. Good experiences and smart branding build trust. Eco-friendly materials attract people who care about nature. When people buy again, it shows they like quality and responsibility.

| Strategy | Description |

| Custom Bags | Custom bags show off brands and make people remember them. |

| Durability and Design | Strong and nice bags help keep customers coming back. |

| Memorable Experience | Fancy bags make opening them fun and help people remember. |

| Professionalism | Branded bags show the company cares and builds trust. |

| Environmental Responsibility | Green materials bring in buyers who care about the earth. |

| Repeat Business | Tough bags get used again and again, helping people remember the brand. |

| Brand Visibility | Branded bags help more people see and remember the company. |

| Differentiation | Special designs make brands stand out from others. |

Happy customers and loyal buyers help companies grow. When businesses care about people and the earth, they make strong bonds that last.

Paper bag makers show that big dreams matter. Hard work can change lives for the better. Andrew’s company makes 22,000 bags every week. He has 20 people working for him now. Andrew proves small ideas can become big. Brenda’s story shows that not giving up brings success.

Brenda says, “My experience changed my life and my family’s life.”

Entrepreneurs can:

Work with suppliers who use recycled materials.

Add QR codes to connect with customers.

Invest in new designs and water-resistant paper.

New ideas, never giving up, and caring for the planet help businesses grow. These things inspire other people too.

FAQ

What makes a paper bag business successful?

A paper bag business does well by trying new ideas. Teamwork is very important for success. Companies that care about the planet do better. They listen to what customers want. They change when new trends come up. These companies show others that being eco-friendly helps them grow.

How do paper bag manufacturers help the environment?

Paper bag makers use recycled things and things that can grow again. They make bags that break down on their own. This means there is less trash and less pollution. Their work helps keep the earth clean. They also help more people pick green packaging.

Can small businesses compete with big paper bag companies?

Yes, small businesses can do well too. They can make special designs and give personal service. They can change quickly when needed. Many start with simple tools and work hard to grow. Their stories show that caring and new ideas are more important than being big.

Why do customers prefer paper bags over plastic?

People like paper bags because they are good for the earth. Paper bags break down fast and come from things that can grow again. Many people feel happy to buy from brands that help the planet.