Paper bag making machine prices can be very different. Some machines cost $20,000. Others can cost up to $500,000. Machines like the Infinity MasterBag 3000 or Ruian XH-330 Fully Automatic cost more than $100,000. If a machine makes bags fast, has custom sizes, or folds the bottom by itself, it costs more. People want a machine that does what they need and fits their budget.

| Type of Machine | Price Range |

| Semi-Automatic | $20,000 - $60,000 |

| Fully Automatic | $50,000 - $500,000 |

Features like eco-friendly bag choices and strong paper handling can change the price and how well the machine works.

Key Takeaways

Paper bag making machines have different prices. Some cost $5,000 for basic models. Others cost up to $500,000 for top models. Pick a machine that matches your budget. Make sure it fits your production needs.

Think about how automatic the machine is. Fully automatic machines save time and work. They cost more money. Semi-automatic machines cost less. They are good for small businesses.

Check for features that make the machine better. Eco-friendly options help the environment. Customization lets you change how bags look. These features can change the price. They also affect how well the machine works.

Take care of your machine often. This helps it last longer. Clean and service it as the maker says. This stops expensive repairs.

Look up brands you can trust. See what warranties they offer. Good warranties help you save money later. Reliable customer support is important too.

Paper Bag Making Machine Models

Manual and Semi-Automatic Models

Many people pick manual or semi-automatic machines when starting out. These machines are good for small shops or special orders. Manual machines are best for stores that only need a few bags. Semi-automatic machines are faster but still need some help from workers. These machines work well for small and medium businesses.

Here are some well-known models and what they do:

| Machine Type | Distinguishing Features |

| V Bottom | Makes bags with a V-shaped bottom, great for bakeries and delis. |

| Square Bottom | Bags stand up straight, use two layers of paper, and are used in stores. |

| Handle Bag Machines | Puts handles on bags, so they are easy to carry, with one or two handle choices. |

| Mini and Entry-Level | Small and not expensive, good for new businesses, costs $15,000 to $30,000. |

Semi-automatic machines are quicker than manual ones. They are good for businesses that want to get bigger but do not need to make lots of bags yet.

Fully Automatic and Sheet Fed Models

Fully automatic machines are great for making lots of bags fast. These machines do most of the work by themselves. Big factories and packaging companies use them for large orders. Sheet fed machines are also in this group. They use big sheets of paper and can make different bag sizes.

Let’s look at how they compare:

| Feature | Fully Automatic Machines | Semi-Automatic Machines |

| Automation Level | Needs little help, works very fast | Needs people to help |

| Production Capacity | Makes lots of bags, good for big companies | Makes fewer bags, good for smaller businesses |

| Cost and Investment | Costs more money, needs a bigger budget | Costs less, easier for small businesses |

| Operator Skill and Training | Simple to use, not much training needed | Needs skilled workers |

| Flexibility and Customization | Can make many bag types and sizes | Not many choices for bag styles |

Some models, like the MTED RZFD-330/450, are known for being fast and having cool features.

Square Bottom and Specialty Machines

Square bottom machines make bags that stand up on their own. Stores and bakeries like these because the bags hold more and look nice. Specialty machines can do extra things, like add handles or make bags for food.

Here is how square bottom machines are different:

| Feature | Square Bottom Machine | Standard Machine |

| Bag Shape | Has a square or rectangle bottom | Has flat, gusset, or satchel shapes |

| Bottom Formation | Uses special folding and glue steps | Uses other ways for each bag style |

| Bag Design | Strong and roomy, good for stores and groceries | Many designs for gifts or takeout |

| Bag Size Range | Only makes commercial sizes | Can make many sizes and styles |

These machines help all kinds of businesses pick the best paper bag making machine, from small shops to big factories.

Prices by Model and Features

Entry-Level Price Range

People who want a small business look for entry-level machines. These machines can be manual or semi-automatic. They do not cost much and are good for shops with less money. Most entry-level machines cost between $5,000 and $20,000. Semi-automatic machines in this group make simple bags fast. Workers still need to help with some steps.

| Type of Machine | Cost Range |

| Manual | $5,000 - $10,000 |

| Semi-Automatic | $5,000 - $20,000 |

People pick these machines to save money. They do not need to make lots of bags quickly. Entry-level machines do not have fancy features like handle attachment or PLC control. They only make basic bag shapes and sizes.

Tip: Entry-level machines let new businesses try selling bags without spending a lot.

Mid-Range Price Range

Mid-range machines have more features and work faster. These models include better semi-automatic and some automatic machines. The price for mid-range machines is usually $20,000 to $95,000. Many businesses buy these machines when they want to grow.

Technology Level and Degree of Automation: Machines with more automatic parts cost more. They help save on worker costs.

Production Speed and Capacity: Machines that make over 150 bags each minute cost extra. They use stronger parts.

Functional Configuration and Customization: Machines with choices for custom bag sizes or handle attachment cost more.

| Type of Machine | Cost Range |

| Fully Automatic | $20,000 - $150,000 |

| Sheet Fed | $10,000 - $500,000 |

Mid-range machines often have PLC control. This makes them easier to use. Some models add eco-friendly bag features or special folding. These features help businesses meet customer needs and follow new packaging rules.

Note: Prices change by region. In Asia-Pacific, fast growth and green rules make prices higher. North America and Europe have higher prices because people want eco-friendly packaging.

Premium Price Range

Premium machines have the most automation and advanced features. These models include fully automatic, square bottom, and specialty machines. Premium machines cost from $50,000 to $500,000. Some square bottom machines cost up to $250,000. Big companies with large orders or special needs buy these machines for speed and flexibility.

| Feature | Price Impact | Cost Reduction |

| IoT integration | Adds 15-20% | Cuts operational costs by 30% |

| Multi-functional systems | 25-50% premium | N/A |

| High-speed machines | 2-3x more | N/A |

Premium machines have IoT integration, multi-functional systems, and high-speed production. These features make the price go up. They help companies save money over time. Fully automatic machines in this group make many bag types and sizes. They need little help from workers.

Callout: Rules against plastic bags make premium machines more popular. Incentives for eco-friendly products help lower costs for buyers.

People who buy premium machines use financing to pay. Banks, equipment financing, and vendor payment plans help make these machines affordable. Some governments give grants or tax breaks for buying eco-friendly machines.

| Financing Option | Description |

| Bank Loans | Need collateral, lower interest rates. |

| Specialized Equipment Financing | Flexible terms, quick approval. |

| Operating Lease | Rent for a set time, no need to buy. |

| Finance Lease | Lease-to-own, buy after lease ends. |

| Direct Vendor Financing | Pay in installments, less upfront cost. |

| Deferred Payments | Pay later while earning revenue. |

| Government Grants & Subsidies | Tax breaks or cash for green machines. |

| Crowdfunding & Partnerships | Get funds from investors or social groups. |

People should look at prices and features before buying a machine. Automatic models cost more but save time and worker costs. Fully automatic machines with advanced features help big companies fill big orders. Semi-automatic machines are good for smaller businesses with less money.

Features That Affect Price

When people look at paper bag making machines, they see prices change a lot. This happens because each machine has different features. Let’s talk about the main features and how they change the price.

Automation Level

Automatic machines do most jobs by themselves. They use smart tools like AI to cut and check for mistakes. These machines work fast and make fewer errors. People pay more for fully automatic machines, but they get better results and save on worker costs.

Automatic systems help cut bags and find mistakes.

Machines with automatic checks need less help from people, so bags look the same.

AI helps keep machines working well and stops big problems.

Fully automatic machines cost more because they use smart technology and give big benefits.

People who want fewer mistakes and faster work pick automatic machines. They know paying more now saves money later.

Production Capacity

Production capacity means how many bags a machine makes each minute. This feature changes the price a lot. Machines that make more bags cost more because they use stronger parts and better motors.

| Machine Type | Production Capacity (bags/min) | Cost Range (USD) |

| Manual/Semi-Automatic | Low (1-50) | 5,000 - 15,000 |

| Fully Automatic | Mid (50-200) | 30,000 - 150,000 |

| Fully Automatic | High (300+) | 80,000 - 500,000+ |

Big factories buy automatic machines with high capacity. These machines help fill large orders fast. Energy-saving motors in new models lower costs per bag, especially when making thousands every day. Smart care also helps by making repairs less often, which saves money.

Tip: Paying more for a machine that makes more bags can help you earn more later.

Control Systems and Attachments

Control systems and attachments add more choices to each paper bag making machine. Machines with advanced controls, like PLCs, let workers change settings easily. Automatic changes mean less waiting and better bags.

Semi-automatic machines cost less because people do more work.

Fully automatic machines cost more, but they work better and faster.

Extra features, like making bags with more layers or special sizes, raise the price.

Top models have PLC systems and automatic changes, so they cost more.

More automation means higher price, but it saves on worker costs and makes work easier.

Attachments like handle makers or folding units also make the price go up. People who want more features should plan to pay extra. Buying good machines with smart technology gives better results and less waste, so you make more money over time.

Note: New machines use less power, so they save money and help the planet. Buyers should think about both the price and how much they save later.

New vs. Used Machine Prices

Price Comparison

People think about buying new or used paper bag making machines. The choice depends on how much money they have and what they need. New paper bag making machines cost more money. They have the newest automatic features and better warranties. Used paper bag making machines cost less. They may not have the newest technology.

Here is a table that shows the price difference:

| Machine Type | New Machine Price | Used Machine Price |

| Manual | $5,000 - $10,000 | $2,000 - $6,000 |

| Semi-Automatic | $10,000 - $30,000 | $5,000 - $18,000 |

| Fully Automatic | $30,000 - $500,000 | $15,000 - $250,000 |

| Square Bottom Automatic | $50,000 - $250,000 | $25,000 - $120,000 |

Tip: Used paper bag making machines help small businesses save money. Buyers should check if the machine works well before buying.

Feature Differences

New paper bag making machines have more automatic features. They use smart controls, faster motors, and save energy. Used paper bag making machines might not have these new systems. Some used machines still work well for simple jobs.

New machines can add handles automatically and use PLC controls.

Used paper bag making machines may not have new upgrades, but they still make bags fast.

People with less money often buy used paper bag making machines for easy jobs.

New paper bag making machines are good for companies that want fast work and less stopping.

Used paper bag making machines may need more repairs, which can cost more later.

Note: People should pick a machine that fits their budget and needs. New paper bag making machines with automatic features save time and money. Used paper bag making machines are good for people starting a business.

Value Comparison for Different Needs

Small Business Options

Small businesses want machines that do not cost a lot. They also want good features. These machines should be easy to use. They should make different bag sizes. Many people pick models that are ready to ship. These do not need a big investment. Here are some popular choices:

| Model | Type | Price | Features |

| W&H Triumph 1 S 1271 | SOS paper bag machine | €20,000 | Makes bags 120-350 mm long, 50-120 mm wide. Ready to use. |

| Holweg RS 12 Roto Simplex | Flat/satchel bag machine | N/A | Bag width 50-330 mm, 3 color printer included. |

| Profama SOS 030-CE | SOS bag machine | N/A | Bags up to 340 mm wide, 6 colors, 2 plies. |

| Low Cost Paper Bag Machine | Fully automatic | N/A | Touch screen, servo control, makes many bag types. |

| Automatic Paper Bag Machine | Shopping bag | N/A | 1000 pcs/hr, strong bags, easy to maintain. |

Tip: Start with a cheaper model. Upgrade later when you have more money.

Large-Scale Production Choices

Factories and big companies need machines for lots of bags. These machines work fast and have strong motors. They help save money over time. They cost more at first. Here are some top picks:

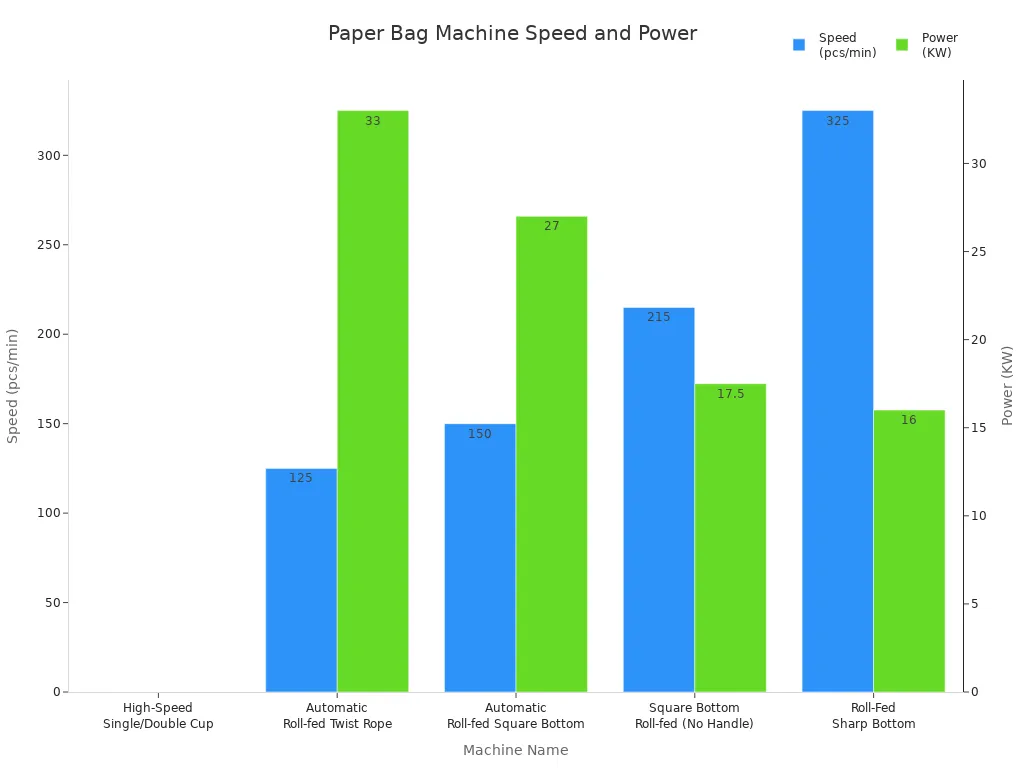

| Machine Name | Daily Capacity | Speed (pcs/min) | Power (KW) | Benefits |

| High-Speed Single/Double Cup Paper Bag Machine | Over 200,000 bags | N/A | N/A | Great for food and coffee bags, very efficient. |

| Automatic Roll-fed Twist Rope Paper Bag Machine | N/A | 100-150 | 32-34 | Flexible, fast, and easy to adjust. |

| Automatic Roll-fed Square Bottom Machine | N/A | Up to 150 | 25-29 | Saves space and cuts waste. |

| Square Bottom Roll-fed (No Handle) | N/A | 150-280 | 8-27 | High output, less labor needed. |

| Roll-Fed Sharp Bottom Machine | N/A | 150-500 | 16 | Makes eco-friendly bags, works reliably. |

![Bar chart comparing speed and power of recommended paper bag making machines for large-scale production]()

Callout: Big buyers should check machine speed and power. Pick what fits your budget and daily needs.

Specialty Bag Solutions

Some companies need special bags for food or green packaging. Specialty machines cost more money. They have unique features. Here are some starting prices:

| Machine Type | Starting Price |

| Eco-friendly food paper bag machine (various types) | $60,000 |

| Fully Automatic High-Speed Square Bottom Paper Bag Machine with Twisted Handle | $160,000 |

| Roll-Fed Square Bottom Paper Bag Making Machine | $90,000 |

Note: Specialty machines help companies be different. Buyers should plan their budget to get the right features.

Tips for Choosing Reliable Machines

Picking a reliable paper bag making machine can be hard. Many people want a machine that works well and lasts a long time. They also want a brand they can trust. Here are some tips to help you choose wisely.

Trusted Brands

Some brands are known for making good machines. These companies have a strong reputation. Their machines work well for many years. Here are some brands people trust:

Newlong: Makes accurate machines for many paper types. Big packaging companies use their machines.

Holweg Weber: This is one of the oldest brands. Their machines help lower carbon footprint by 15%. They care about eco-friendly solutions.

Windmoller & Holscher: Sells modern machines with advanced features. Many users save 25% on production costs.

Sunhope: Offers affordable machines for all business sizes. Many new businesses pick this brand.

Buyers should look for quality, durability, and good reviews when picking a brand.

Tip: Trusted brands break down less and give better help when problems happen.

Warranty and Support

Warranty and support are very important when buying a machine. Good support keeps the machine working and helps avoid long stops. Most top brands give a one-year warranty. They also give free replacement parts during this time. Some companies, like Xinke and Oyang, offer extra help. This includes video calls, on-site visits, and training.

| Manufacturer | Warranty Period | Free Replacement Parts | Paid Maintenance Services | After-Sales Support |

| Paper Bag Machinery Manufacturer | 1 year | Yes | Yes (if improper use) | Online help, training, on-site installation |

| Xinke | 1 year | Yes | Yes (if improper use) | Video calls, on-site, training |

| Oyang | 1 year | Yes | Yes (after warranty) | Setup help, local support, spare parts |

Cleaning the machine often and checking for worn parts helps it last longer. Lubricating moving parts is also important. Preventive care stops big repairs and saves money over time.

Note: Good after-sales support and a strong warranty can lower the total cost of owning a machine.

Picking the best paper bag making machine is not easy. You need to think about your budget and what features you want. Buyers have trouble comparing machines and prices. The table below lists things to think about:

| Factor | Description |

| Level of Automation | Fully automatic machines cost more but work faster. |

| Production Capacity | Fast machines need more money to buy. |

| Brand Reputation | Good brands give better help and last longer. |

| Additional Features | Printing and extras make machines cost more. |

| Equipment Specifications | Advanced machines work better but cost extra. |

Buyers should remember these tips:

Pick a machine that makes the right bag size.

Make sure the machine can grow with your business.

Choose how much automation you need.

Look for strong and good quality machines.

Check if you can get help and spare parts.

It is hard to compare machines because they are all different. Prices change and features are not the same. The best choice is a machine that fits your budget and has the most useful features for your business.

FAQ

What is the best paper bag making machine for beginners?

Most beginners pick semi-automatic or entry-level machines. These machines cost less money and work for small orders. They are simple to use and need little training. Many small shops start with these machines.

How often should a paper bag making machine get maintenance?

Regular care helps the machine run well. Most brands say to check and clean the machine every week. Lubricate moving parts and change old pieces when needed. Good care makes the machine last longer.

Can one machine make different bag sizes?

Yes, many modern machines can make different bag sizes. Operators change the settings or swap some parts. Some models switch sizes faster than others. Always read the machine’s manual for details.

Do paper bag machines need special power requirements?

Some machines need more power, especially fully automatic ones. Always look at the machine’s power rating before buying. Most small machines use normal outlets, but big machines may need special wiring.

Is it better to buy a new or used paper bag making machine?

New machines have the newest features and better warranties. Used machines cost less and work for simple jobs. Buyers should check the machine’s condition and support before choosing.