You can begin a paper bag manufacturing business by setting up a production unit. You need to find good materials and buy efficient machines. The global market for eco-friendly packaging is growing fast. The paper bag packaging market may reach USD 8.50 billion by 2032. Many industries now like to use paper bags. These include food, retail, and e-commerce. This complete guide will help you make a business that earns money and helps the planet. Use this guide to learn every step of the paper bag manufacturing business. The guide gives helpful tips for people who want to start or grow a paper bag business.

Key Takeaways

Learn about market trends. Pay attention to what people like and care about. Focus on sustainability to get more customers.

Make a strong business plan. Set clear goals for your company. Do good market research to help you make choices.

Pick good materials and trusted suppliers. This helps you make strong and eco-friendly paper bags. Your bags will meet what customers want.

Buy the right machines for your business. Choose machines that match your goals and budget. This will help you work better and faster.

Follow all legal rules for your business. Register your company and obey environmental laws. This will help you avoid problems.

Market Overview

Demand & Trends

People want more paper bags in many places. The paper bags industry is changing quickly. People care about the environment and want better options. There are some important trends you should know:

Sustainability focus: Many people and businesses want packaging that breaks down and can be recycled. This makes paper a popular choice.

Regulatory changes: Some countries do not allow single-use plastics. This makes companies use paper bags instead.

Consumer preferences: People like products that help the environment. This makes more companies use paper for packaging.

Technological innovations: New machines and ways of making bags help you create stronger and better paper bags.

Customization opportunities: Brands use paper bags to show their logos and designs. This makes each bag special.

You can see these changes everywhere in the industry. The paper bags industry keeps getting bigger as more people care about the earth. You can use these trends to plan your business and help your customers.

Tip: Keep learning about new trends in the paper bags industry. This helps you stay ahead of other companies.

Competition

There are many companies in the paper industry. Some have made big changes to become leaders. Here are some recent updates from top companies:

| Company Name | Recent Development |

| Novolex | Bought American Twisting’s assets in September 2024 to grow in the market. |

| International Paper & DS Smith | Joined together in April 2024 to become a global leader in sustainable packaging. |

| Mondi Group | Worked with Taurus Packaging in October 2021 to make reusable paper shopping bags. |

| Smurfit Kappa | Spent USD 40 million in Latin America in February 2021 to improve paper sacks operations. |

| Novolex | Bought B&H Bag company in December 2020 to make more bags. |

You will compete with big and small companies in this field. Many work hard to make great paper bags and improve how they make them. You can learn from these top companies and find your own way to be different. Watch how things change and use new ideas to help your business grow.

Business Planning

A strong business plan helps you build a successful paper bag making business. Careful planning guides your decisions and keeps your business on track. You need to set clear goals, understand your market, and plan your finances. Each step in business planning shapes your path in the paper industry.

Goals & Vision

You should start your paper bag making business with a clear vision. Decide what you want your business to achieve in the long run. Many successful companies in the paper industry focus on meeting rising demand and staying ahead of trends. You can use the table below to see what matters most for long-term success:

| Aspect | Details |

| Market Demand | Environmental awareness increases demand for paper bags in many industries. |

| Customer Willingness | Customers often pay more for products with responsible packaging. |

| Market Positioning | Good positioning and quality supply help you reach a growing market. |

| Understanding End Users | Knowing what retail stores and buyers need helps you plan production. |

| Adapting to Trends | Adapting to new materials and techniques keeps your business ahead of competitors. |

Set goals that match your vision. For example, you might want to become a top supplier for local supermarkets or create custom paper bags for retail brands. Your business plan should show how you will reach these goals. Planning for growth helps you stay focused and ready for changes in the market.

Tip: Write down your goals and review them often. This keeps your business moving in the right direction.

Market Research

Market research gives you the facts you need to make smart choices in your paper bag making business. You learn what customers want and how other companies work. Good research helps you find your target market and plan your products.

Understand Market Demands: Study trends and see which paper bag styles are popular.

Consumer Preferences: Use online tools to check what designs people like, such as eco-friendly or reusable bags.

Competitor Analysis: Make a list of other brands. Look for gaps in the market where your business can stand out.

Target Niche Identification: Divide the market into groups, like grocery stores or clothing shops. Each group has different needs.

Practical Research Methods: Talk to potential customers. Use surveys or focus groups to learn what they want from paper bags.

You can use this information to shape your business plan. When you know what customers want, you can design paper bags that sell well. You also learn how to price your products and where to sell them.

Note: Market research is not a one-time task. Keep checking trends and customer needs as your business grows.

Financial Projections

Financial planning is a key part of your business plan. You need to know how much money you need to start your paper bag making business and how much you can earn. Startup costs can change based on the size of your manufacturing unit and the type of machines you buy. The table below shows common cost ranges:

| Description | Cost Range |

| Small, semi-automated operation | $50,000 |

| Large-scale, fully automated | Over $500,000 |

| Mid-range budget for EcoWrap Bags | $150,000 to $250,000 |

| Typical startup costs | $122,000 to $308,000 |

| Overall total startup costs | $106,000 to $555,000 |

You should include all costs in your business plan. These costs include machines, raw paper, labor, rent, and marketing. Estimate how many paper bags you can sell each month. Plan for your income and expenses for at least the first year. This helps you see when your business will start making a profit.

Tip: Review your financial plan often. Adjust your numbers as you learn more about your business and the market.

Careful planning gives your paper bag making business a strong start. When you set clear goals, study the market, and plan your finances, you build a business that can grow and succeed in the paper industry.

Legal Requirements

When you start a paper bag manufacturing plant, you must follow the law. You need to make sure your business follows all the rules. This is important before you start making paper bags. It helps you avoid trouble and keeps your plant working well.

Registration & Licenses

You have to register your paper bag manufacturing plant with the right office. The kind of registration depends on your business size and what you want to do. Here are the main registrations and licenses you might need:

Pick a business structure. You can choose sole proprietorship, partnership, LLC, or corporation. Each one has different tax and liability rules.

Get a manufacturing license if your area asks for it. This license lets you run your paper bag manufacturing plant legally.

Apply for pollution control clearance. If your plant uses chemicals or makes emissions, you must show you can control pollution.

Get local municipal permits. These permits check that your plant follows safety codes, zoning laws, and fire rules.

Follow environmental regulations. You must handle waste and control how your plant uses water and other materials.

Tip: Always ask your local government about the latest rules. Laws can change, so you want your paper bag manufacturing plant to stay legal.

Permits & Compliance

You also need to meet safety and environmental rules in your paper bag manufacturing plant. Many countries use ISO standards to help set these rules. The table below shows two important ISO standards for paper plants:

| ISO Standard | Key Requirements |

| ISO 14001 | Make an environmental policy, find impacts, follow rules, set goals to lower harm, control operations, and check progress. |

| ISO 45001 | Make a safety policy, find hazards, follow laws, plan for emergencies, involve workers, and make safety better. |

Meeting these standards helps your paper bag manufacturing plant keep workers and the environment safe. You earn trust from customers and show you care about safety and the planet.

Sourcing Materials

Paper & Supplies

You have to pick the right materials for your paper bag business. The kind of paper you use changes how strong and nice the bag looks. It also changes how much it costs. Most businesses use kraft, recycled, or specialty paper. Each one has its own features and price.

| Paper Type | Typical Cost Level | Main Features |

| Kraft | Low to Medium | Strong, stable price, common |

| Recycled | Medium | Eco-friendly, higher process cost |

| Specialty | High | Unique look, extra processing |

You might need extra supplies too. Water-resistant coatings can add a little cost to each bag. Thin paper needs more coating, so it costs more. If you make bags for food, you must use food-safe additives. These should not be more than 0.5% of the paper’s weight. Extra coatings and labels for food safety will make your costs go up.

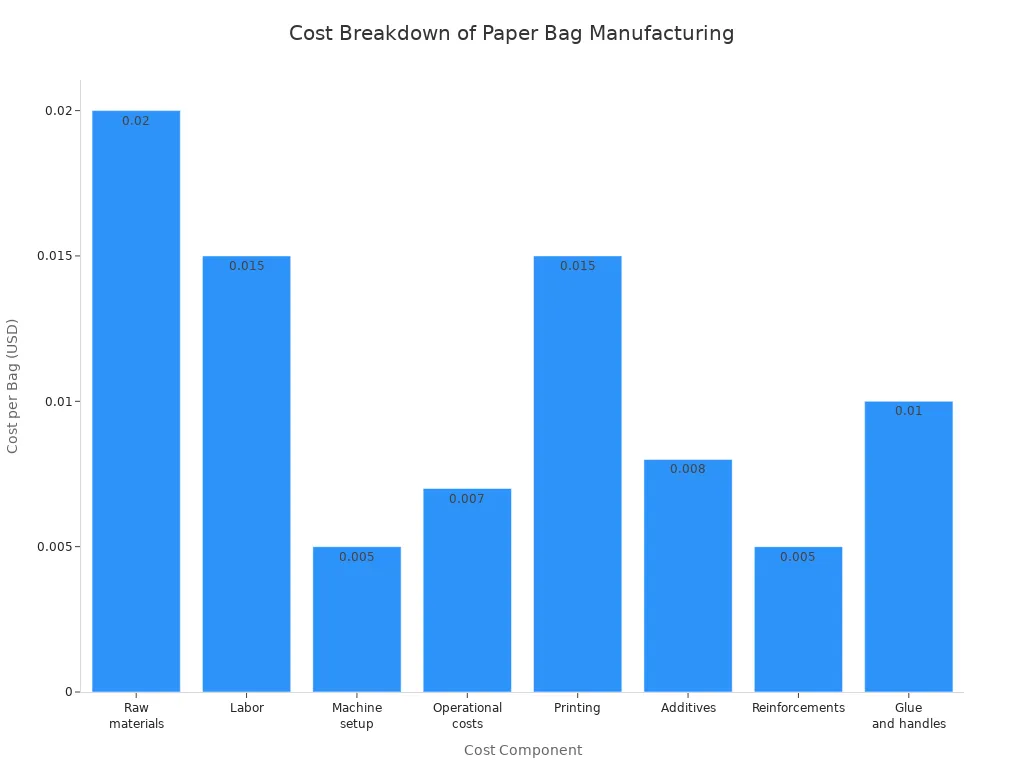

Here is a list of the main costs for each bag:

| Cost Component | Cost per Bag (USD) |

| Raw materials | $0.020 |

| Labor | $0.015 |

| Machine setup | $0.005 |

| Operational costs | $0.007 |

| Printing | $0.015 |

| Additives | $0.008 |

| Reinforcements | $0.005 |

| Glue and handles | $0.010 |

| Total | $0.085 |

![Bar chart showing cost per bag for each supply in paper bag manufacturing]()

Tip: Watch your supply costs often. This helps you keep your prices fair and your business making money.

Supplier Selection

You need to choose suppliers who help you make good paper bags. Good suppliers give you strong materials and help you reach your goals. Use these ideas to pick the best supplier:

Quality of materials

Customization options

Sustainability practices

Pricing

Customer service

Supplier reputation

Ask for samples before you buy a lot. Check if the supplier can give you special paper or coatings. Good suppliers help you keep your work smooth and your customers happy.

Note: Make strong relationships with your suppliers. Talking often helps you get better deals and a steady supply.

Machinery & Setup

Choosing Machines

You need a good machine to make paper bags. The machine you pick changes how fast you work. It also changes how nice your bags look and how much you spend. Most businesses use semi-automatic or fully automatic machines. Some choose high-speed or special machines for unique bags. Think about your budget and the kind of bags you want to make.

Here is a table that shows popular machine types and their price ranges:

| Machine Type | Price Range (USD) |

| Semi-Automatic | $20,000 - $60,000 |

| Fully Automatic | $50,000 - $500,000 |

| Mid-Range | $20,000 - $100,000 |

| High-Speed | $100,000 - $300,000 |

| Specialty Models | $80,000 - $100,000 |

| Basic Models | Starting from $80,000 |

Pick a machine that fits your needs. If you want to start small, use a semi-automatic machine. If you want to grow fast, pick a fully automatic or high-speed machine. These help you make more bags quickly. Always check what the machine can do before you buy it.

Tip: Ask to see the machine work before you buy. This helps you know if it fits your paper and your setup.

Production Layout

A smart setup helps you work faster and safer. Plan where each machine goes in your factory. Think about how materials move from one place to another. This saves time and keeps your work smooth.

Here are some best practices for designing your production layout:

| Principle | Description |

| Material handling | Move materials quickly and easily. |

| Workflow | Make sure each step goes smoothly to the next. |

| Space utilization | Use your space well so nothing gets crowded. |

| Flexibility | Make your setup easy to change if you need to. |

| Safety | Leave space between machines and use barriers for safety. |

| Employee morale | Make the work area nice so workers feel good. |

Walk through your factory and see if workers can move easily. Keep the path from raw paper to finished bags clear. Put machines in order so you do not have to go back and forth. This helps you make more bags with less work.

Note: Check your setup often. Small changes can help you make bags better.

Paper Bag Manufacturing Process

The paper bag manufacturing process turns raw materials into strong, useful bags. You need to follow each step carefully to make sure your bags meet quality standards. This process helps you create products that customers trust and want to use.

Step-by-Step Workflow

You can follow these steps to complete the paper bag manufacturing process from start to finish:

Material Selection & Procurement

Start by choosing the right raw materials. You can use kraft paper, white paper, or recycled paper. Good materials help you make strong bags.

Pulping Process

Next, you break down the raw materials. You chip, cook, and bleach them to make pulp. This step prepares the paper for the next stage.

Sheet Formation

Press and dry the pulp to form sheets of paper. Roll these sheets so you can use them in the next part of the process.

Cutting and Folding

Cut the paper sheets into the right size for your bags. Fold them into the basic bag shape. This step sets the size and style of your product.

Gluing and Sealing

Apply industrial glue to the seams and edges. This keeps the bag strong and stops it from coming apart.

Printing and Customization

Print logos, designs, or other features on the bag. Custom printing helps your customers show off their brand.

Quality Control

Test each bag for strength and look for any problems. Only send out bags that pass your checks.

Tip: Always check your machines and tools before you start the process. This helps you avoid mistakes and keeps your manufacturing process smooth.

Packaging & Storage

After you finish the paper bag manufacturing process, you need to package and store your bags the right way. Good packaging and storage keep your bags in top condition until they reach your customers.

Store your bags flat and stack them neatly. This stops them from bending or tearing.

Use shelving to keep bags off the ground. Shelves protect your bags from moisture and pests.

Keep your storage area cool and dry. High humidity can weaken the paper and cause mold.

Avoid direct sunlight. Sunlight can fade the color and weaken the bag material.

Use storage containers with tight lids for extra protection. These containers keep out insects and humidity.

Organize your bags with a First In, First Out (FIFO) system. This helps you use older stock first and reduces waste.

Check your bags often for signs of damage or moisture.

Note: Regular inspections help you catch problems early. You can fix issues before they affect your customers.

Quality Control and Efficiency Tips

You need strong quality control to make sure every bag meets your standards. Start by checking all raw materials before you use them. Watch the process as you work to catch any mistakes early. Test your bags for strength using mechanical tests like tensile checks. Keep good records of your tests and inspections. This helps you track problems and find ways to improve.

Inspect raw materials before starting the process.

Monitor key steps in the manufacturing process.

Use mechanical tests to check bag strength.

Keep records for every batch of bags.

Train your team to spot and fix problems quickly.

Review your process often and look for ways to improve.

Tip: Continuous training and regular audits help your team keep quality high. Small changes in your process can make your paper bag manufacturing more efficient.

By following these steps, you can run a paper bag manufacturing process that creates strong, reliable bags. Good packaging and storage protect your finished products. Quality control at every stage helps you build a business that customers trust.

Team & Training

Building a strong team helps your paper bag manufacturing business run smoothly. You need people with the right skills and a good attitude. Training your staff makes sure everyone knows how to do their job well.

Roles Needed

You need several key roles in your factory. Each person has important tasks. The table below shows the main roles and what they do:

| Role | Responsibilities |

| Paper Bag Machine Operator | Set up and run machines. Check machine performance. Fix problems quickly. Keep work area clean. |

| Record production data. Work with others to meet goals. |

| Bag Worker | Operate machines to make bags. Inspect bags for defects. Package finished bags. |

| Clean equipment. Manage supplies. Follow safety rules. Track production. Help improve processes. |

You need people who pay attention to detail and care about quality. Machine operators should have experience with industrial machines and know how to fix small problems. Bag workers need to work well in a team and keep things organized.

Tip: Hire people who want to learn and grow. This helps your business improve over time.

Staff Training

Training helps your team work better and safer. You should teach new workers how to use machines and follow safety rules. Good training programs make your business more efficient and help you avoid mistakes.

Here are some benefits of staff training:

| Benefit | Description |

| Quality Assurance | Workers learn to follow steps that keep bags strong and safe. |

| Efficiency and Productivity | Training helps workers finish tasks faster and waste less material. |

| Employee Training | New workers learn quickly and make fewer mistakes. |

You can use hands-on lessons and simple guides. Show workers how to check for defects and keep machines clean. Teach them how to report problems and work together. Regular training keeps everyone up to date with new methods and safety rules.

Note: Review your training program often. Update it when you add new machines or change your process.

A well-trained team helps you make high-quality paper bags and keeps your business running smoothly.

Finances & Costs

Initial Investment

You must plan your money before starting your paper bag business. The first thing to do is know how much you need at the start. This first investment pays for everything to open your factory. You will need money for machines, raw paper, space, and setup. Most people spend between $160,000 and $540,000 to begin.

$160,000 is enough for a small or simple factory.

$540,000 is needed for a bigger or more advanced factory.

Pick how much to spend based on your goals and market size. If you spend more, you can buy better machines and make more bags. If you spend less, you take fewer risks. Always save some extra money for surprise costs.

Tip: Write down every cost you can think of. This helps you stay ready and keeps your business safe.

Operating Expenses

Once your paper bag business is running, you will have regular costs. These costs affect how much money you make and how long your business lasts. You should watch each cost and try to save money where you can. Here are the main costs you will have in your paper bag business:

| Operating Expense | Description |

| Raw Materials | Money for paper and other things to make bags. |

| Utilities | Money for power, water, and other services for your factory. |

| Transportation | Money to move materials to your factory and bags to buyers. |

| Packaging | Money to pack the finished paper bags. |

| Salaries and Wages | Money paid to workers who help make and sell the bags. |

| Depreciation | The loss in value of your machines and tools over time. |

| Other Expenses | Extra money for repairs, upkeep, or small items. |

You can save money by buying paper in large amounts, using machines that use less energy, and teaching your team to work well. Check your costs every month. This helps you find problems early and keep your business healthy.

Note: Keeping your costs low helps your paper bag business make money and grow in the future.

Marketing & Sales

Branding

Branding is how people think about your business. When you put your logo on bags, people see it everywhere. Each bag acts like a small ad for your company. People notice your design when someone carries your bag. This helps more people learn about your brand and makes you different from others.

Using good, eco-friendly materials helps people trust your business. Many customers want to buy from companies that care about the earth. A strong brand also means giving people a good experience. If someone gets a strong and nice-looking bag, they remember your business. Special designs and fun details make your bags stand out. This can make people want to buy from you again.

Tip: A cool bag design can get people talking about your business. Make your packaging something customers want to share.

Here are some ways to make your brand stronger:

Pick bright colors and easy-to-read logos for your bags.

Use earth-friendly materials to show you care.

Give out reusable bags so people come back.

Team up with local artists for special bag designs.

Promotion Strategies

You need to use both online and offline marketing to find more customers. Start by talking to local stores and supermarkets. Go to these places and show them your bags. Tell them how your bags help them be more eco-friendly.

For online marketing, post pictures of your bags on social media. Put QR codes on your bags so people can scan them. This can give them discounts or let them follow your business online. This way, your online and offline marketing work together.

Offline, join local events or help with community projects. Work with local artists to make special bags for your area. These ideas make your marketing different and help you meet new customers.

This table can help you plan how to market and sell your paper bags:

| Channel | Action Item |

| Local Retailers | Show samples, meet in person |

| Social Media | Post bag photos, hold contests |

| Events | Sponsor, hand out sample bags |

| QR Codes | Give discounts or link to social |

Note: Keep marketing your business so people remember you. Try new things and see what works best for selling your bags.

Challenges & Solutions

Common Issues

Starting a paper bag business is not always easy. Many new owners face problems that slow down their business or make them lose money. Here are some common problems you might see:

More companies join the market, so you may need to lower prices to keep up.

Getting raw materials is hard, especially when paper prices change a lot.

If you do not have enough skilled workers, it is hard to keep quality high.

You must handle waste well and follow environmental rules to keep your factory clean.

Tip: Watch for these problems early. Fixing them soon helps you avoid bigger trouble later.

Overcoming Obstacles

You can fix many problems with good planning and simple steps. Here are some easy ways to help your new paper bag business:

Start small so you can test your ideas and not spend too much money.

Rent basic machines first. This saves money and lets you upgrade later.

Ask suppliers for lower prices when you buy a lot of recycled paper.

Use local materials to save on shipping and delivery costs.

Pick machines that use less energy. This can cut your energy use by about 20%.

Try lean manufacturing to use less and waste less.

Plan your delivery routes to spend less on transport.

Note: Check your costs and how you work every month. Small changes can help you make more money.

If you face problems and use these tips, your business can grow strong. Stay ready to change and keep learning as you get bigger.

Sustainability & Trends

Eco-Friendly Practices

You can help your paper bag business stand out by using green methods. Many companies now care about the environment to meet what customers want. Try to use less waste and save resources. The table below shows some top eco-friendly practices in paper bag manufacturing:

| Eco-Friendly Practice | Benefits |

| Use of recycled materials | Cuts down on plastic waste and gives people what they want—green products |

| Development of biodegradable alternatives | Breaks down naturally and helps the earth stay clean |

| Adoption of plant-based polymers | Uses plants instead of plastics, which is better for nature |

| Implementation of water-soluble packaging | Melts in water, so there is less trash left behind |

| Consumer education strategies | Teaches people why green choices are good and gets them to care |

You can pick recycled paper or plant-based stuff to make your bags. Biodegradable bags break down fast and help keep nature safe. Water-soluble packaging is a new way to cut down on trash. Teaching your customers about green packaging builds trust and shows you care about the planet.

Tip: When you pick green materials, you help nature and get more customers who like eco-friendly products.

Industry Innovations

The paper bag industry keeps changing as new ideas come out. You can use these trends to make your business greener and work better. Here are some new things shaping paper bag manufacturing:

New machines can make up to 2,000 bags every hour. You get better bag sizes and use glue smarter.

Smart factories use IoT and special checks to spot problems early. This keeps your machines working well.

Green materials now use fibers from farm waste and bioplastics. These choices make your bags better for the earth.

Factories now try to make less pollution and almost no waste.

You can stay ahead by using these new ideas. When you try new tech and materials, you show customers you care about the planet. This helps your business grow and keeps you ready for what comes next.

Complete Guide: Next Steps

Action Plan

You now know the main steps to start your paper bag business. Next, you need a simple plan to help you move forward. Try these steps to get your business going in the right way:

Get all the permits and licenses you need. This keeps your business safe and legal.

Use eco-friendly ways to make your bags. Green methods bring in more customers who care about the earth.

Make your brand special. A strong brand helps people notice your bags.

Sell your paper bags in many places. Try local shops, online stores, and at community events.

Give great customer service. Listen to what people say and fix problems fast. Happy customers will come back and tell their friends.

Tip: Check how your business is doing every month. Change your plan if you find better ways to work.

Resources

There are many places that can help your paper bag business grow. Groups and government programs give support, training, and good information. The table below shows some things you can use:

| Benefit/Service | Description |

| Advocacy | Helps the US paper bag and sack industry. |

| Economic Efficiency | Shows ways to save money by working together. |

| Education | Teaches about the good things for the earth and your business. |

| Technology Trends | Shares new ideas for making paper bags. |

| Supplier Access | Helps you find suppliers for your materials. |

| Safety Reports | Gives tips to keep your business safe. |

| Statistical Information | Shares facts and numbers to help you plan. |

| Information Exchange | Lets you talk with others in the industry. |

| Industry Orientation | Offers low-cost training like Bag Boot Camp. |

| Legislative Support | Helps you learn and follow the rules. |

| Financial Transparency | Makes sure costs are clear and fair. |

You can also get help from the Paper and Packaging Board. This group works to make the paper packaging market bigger. It helps businesses like yours and shares news about kraft paper and other products. Many programs come from groups and government grants, so look for local help in your area.

Note: Joining industry groups gives you training, supplier contacts, and news about trends. This support can help your business grow and do well.

You can start your paper bag manufacturing business by following these steps:

Study the market and check your competition.

Make a strong business plan.

Get all needed licenses and register your business.

Invest in the right machines.

Hire skilled workers and pick a good location.

Buy quality raw materials.

Build your brand and use smart marketing.

Starting now helps you enjoy many rewards:

You help the environment with biodegradable bags.

You offer safer packaging for food.

You give customers sturdy, reliable bags.

Take your first step today and shape a greener future!

FAQ

What is the minimum investment needed to start a paper bag business?

You can start a small paper bag business with about $160,000. This covers machines, materials, and setup. Costs may change based on your location and the size of your factory.

How long does it take to set up a paper bag manufacturing unit?

You can set up your unit in 2 to 4 months. This time includes buying machines, getting permits, and training your team. Planning ahead helps you finish faster.

Do I need special skills to run a paper bag factory?

You do not need special skills to start. You can learn most tasks on the job. Training your team helps everyone work safely and make quality bags.

Can I use recycled paper to make bags?

Yes, you can use recycled paper. Many customers prefer eco-friendly bags. Using recycled paper helps the environment and can lower your costs.

Who are the main buyers for paper bags?

You can sell paper bags to supermarkets, retail stores, food outlets, and online sellers. Many businesses want eco-friendly packaging for their products.