You will see that many things change the price of a paper bag making machine in 2025. These things are raw material price, technology, how much the machine can make, market demand, and government rules. The table below shows how each thing can change cost and production:

| Factor | Impact on Price and Production |

| Raw Material Price | If paper pulp and recycled materials cost more, expenses go up. |

| Energy and Utility Costs | If energy prices go up, it costs more to run the machine. |

| Labor Costs | Skilled workers can make production cost more. |

| Regulatory Compliance | New rules for being green can add extra costs. |

| Technology | Better machines work faster but cost more at first. |

The paper bag making market is growing quickly around the world. Experts think the market will go from $2.1 billion in 2023 to $3.7 billion by 2032. This is because more people want eco-friendly choices and new rules limit plastic bags.

Knowing these things helps you make good choices about price when you buy new machines. Oyang is a top company in the field and gives strong and advanced solutions.

Key Takeaways

The price of raw materials affects machine costs a lot. Watch these prices to plan your budget well.

Machines with automation can lower labor costs. They also help make more bags faster. Think about buying automated machines to save money over time.

Keep up with market trends and supply chain problems. Knowing this helps you buy machines at the right time.

Customization lets you meet what customers want. Pick machines that can change bag designs and how bags are made.

Following environmental rules is very important. Buy machines that are eco-friendly to avoid trouble and get more customers.

Raw Material Costs & Price Impact

Paper & Component Pricing

You need to pay close attention to the price of paper and machine parts when you look at paper bag making machines. Paper is the main material for making bags. Its price can change quickly. When the price of paper goes up, the cost to make each bag also rises. Raw materials like paper, coatings, and printing supplies make up about 60–70% of the final cost of a paper bag. This means that even small changes in paper prices can have a big effect on your total production cost.

Here is a table showing the price range for different types of paper bag making machines in 2025:

| Machine Type | Price Range (RMB) |

| Entry-level semi-automatic | 50,000 - 150,000 |

| Mid-range fully automatic | 150,000 - 400,000 |

| High-end, high-speed lines | 500,000 - 2,000,000 |

You will also see that new machines can cost from 100,000 to over 500,000 RMB, depending on speed and features. Used machines usually cost between $8,000 and $12,000. The price of steel and electrical parts can also change. These changes affect the pricing of the machine itself.

The growth of e-commerce means more people want strong paper bags for shipping. This pushes up demand and can raise the price of materials. Paper bags often cost 2-3 times more than plastic bags. Some stores may choose cheaper options, but many want eco-friendly solutions. New coatings and compostable materials help make bags better for food and liquids.

Supply Chain Effects

Supply chain problems can make the price of a paper bag making machine go up. When there are delays in getting materials or parts, manufacturers face longer wait times and higher shipping costs. These extra costs often get passed on to you, the buyer. If raw material prices go up or there are shortages, production can slow down. This makes machines more expensive and harder to get.

You should know that supply chain issues can change quickly. They can affect both the cost and the timing of your purchase. When you plan to buy a machine, always check for any news about supply chain disruptions. This helps you avoid surprises in pricing or delivery.

Tip: Stay updated on market trends and supply chain news. This helps you make better decisions about when to buy and how much to budget for your paper bag making machine.

Tech Innovations in Paper Bag Making Machines

Automation & Efficiency

Technology is changing paper bag making in 2025. Automation is important for saving money and making more bags. If you pick a machine with automation, you need fewer workers. You can make more bags faster. Machines use IoT sensors and AI to watch how they work. This helps companies fix problems quickly and work better.

Here is a table that shows how automation changes cost:

| Machine Type | Description | Cost Range |

| Semi-Automatic | Needs some people to help with parts | $5,000 to $20,000 |

| Fully Automatic | Works mostly by itself; needs little help | $60,000 to $420,000 |

Automation helps use materials better. It makes less waste and saves money. Fast machines help make more bags. This helps the market grow and keeps up with new trends. You also get machines that use less energy and follow green rules.

Automation means fewer workers are needed.

You get more good paper bags made.

It uses materials better and costs less.

Oyang’s Advanced Features

Oyang is a leader in new technology for paper bag machines. Their fully automatic machines use PLC control. This cuts downtime by 25% compared to manual machines. Oyang’s machines can use paper up to 200gsm. This gives you more choices than other brands. Motors that save energy lower running costs by 15%. This helps your business be more eco-friendly.

Here is a table with Oyang’s special features:

| Feature | Specification | Application Scenario |

| Automation Level | Fully automatic with PLC control | Good for making lots of bags |

| Material Compatibility | Paper (80-200gsm), recyclable materials | Custom bags for stores and online shops |

| Production Speed | 80-120 bags/min | Great for big orders |

| Safety Features | Emergency stop, guardrails, sensors | Keeps workers safe in busy places |

Oyang’s machines let you change bag size and printing designs. You can also set how materials go into the machine. This helps you make bags for stores, restaurants, or online shopping. These features help you meet different needs and follow market changes. Oyang’s focus on new ideas and being green makes their machines a smart buy for companies that want to make more bags and spend less.

Tip: Buying advanced paper bag machines helps your business grow and keeps you ahead of new trends.

Manufacturing & Labor Pricing Factors

Global Labor Trends

Labor costs are different in each country. These costs change the price of paper bag making machines. In some places, workers get paid more each year. Companies must spend more to hire skilled workers. Machines that need lots of workers are cheaper to buy. But you pay more for labor as time goes on. Fully automatic machines cost more at first. You save money later because you need fewer workers. Look at the table below to see how labor needs and prices compare for each machine type:

| Machine Type | Price Range | Labor Requirement |

| Entry-Level | Less than $20,000 | More labor needed |

| Mid-Range | $20,000 - $100,000 | Fewer workers for fully automatic |

| Fully Automatic | Higher cost | Requires less labor |

| Semi-Automatic | Cheaper | Moderate labor needed |

Think about labor costs when you pick a paper bag making machine. If you want to make more bags, choose machines that use less labor. This helps you save money and grow your business.

Tip: Keep an eye on labor costs in your country. This helps you plan your spending and pick the best machine for your needs.

Production Overheads

Production overheads also change how much paper bag making machines cost. You need to think about more than just labor. These costs include how automatic the machine is, how fast it works, and how flexible it is. You pay for the materials and how the machine is built. The brand and where the technology comes from can make the price higher. You also pay for help after you buy the machine. You need to pay for your factory and other buildings. Molds and extra parts cost money too. You must pay for setting up and training. Running and fixing the machine costs money every year.

Here is a list of main production overheads you should think about:

Equipment automation level

Production speed and efficiency

Equipment functionality and flexibility

Equipment materials and manufacturing process

Brand and technology source

After-sales service and technical support

Plant and infrastructure requirements

Mold and accessories costs

Installation, commissioning and training costs

Operation and maintenance costs

Each overhead changes your total cost and how many bags you can make. If you want to keep up with new ideas and market changes, plan for these costs. Companies that buy better machines often grow faster and make more bags.

Note: Always check all overhead costs before you buy a paper bag making machine. This helps you avoid problems and control your spending.

Market Dynamics & Pricing Trends

Demand Shifts

There are big changes in how many paper bag making machines people want. Many businesses use more paper bags now. People care about the environment and want eco-friendly packaging. Food, retail, and online shopping use 25% more paper bags than before. New rules make companies switch from plastic to paper bags. This causes a 22% increase in using paper bags. Because of this, companies buy better machines and make more bags. When more people want machines, prices go up. Materials also cost more. Good paper costs 18% more because of supply chain issues. Making bags now costs 12% more. You should watch these changes. This helps you plan your money and pick the best machine.

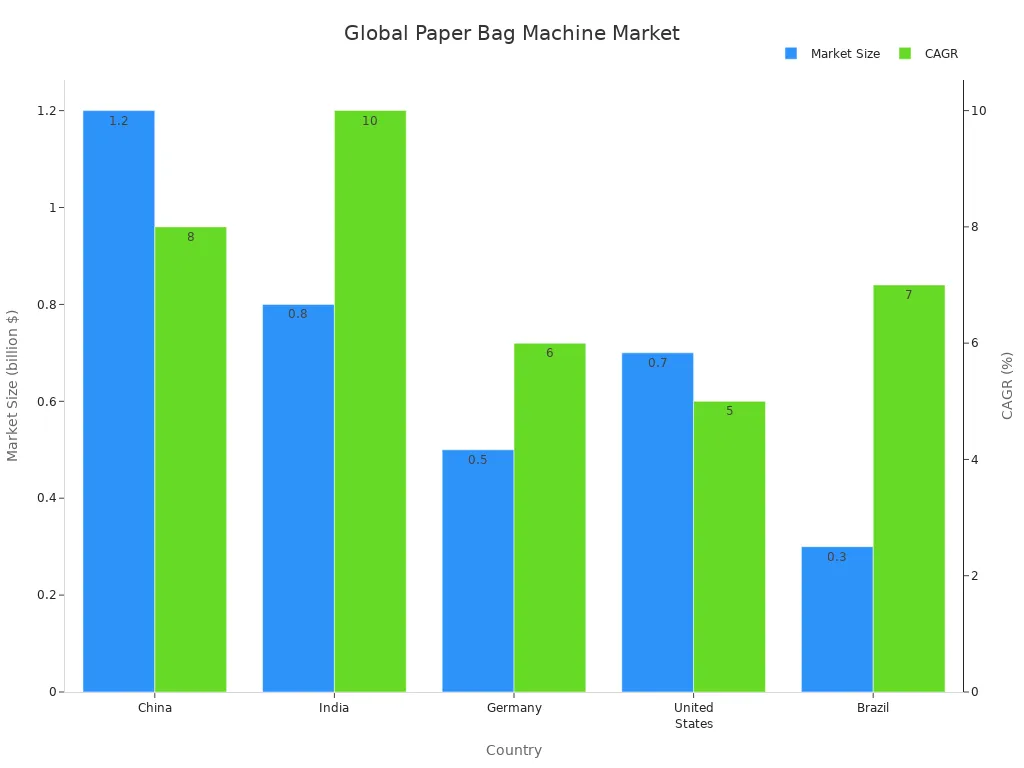

Here is a table that shows market size and growth rates for paper bag making machines in different countries:

| Country | Market Size (in billion $) | CAGR (%) |

| China | 1.2 | 8 |

| India | 0.8 | 10 |

| Germany | 0.5 | 6 |

| United States | 0.7 | 5 |

| Brazil | 0.3 | 7 |

![Bar chart showing market size and CAGR for paper bag making machines by country]()

Competitive Landscape

You have lots of choices when picking a paper bag making machine. Many companies compete in the market. European and American brands make high-quality machines. Chinese companies work to improve their technology and offer cheaper options. This means prices are different for each brand. European brands sell expensive machines with special features. Chinese brands sell machines that cost less and work fast. The market grows by 6.9% every year from 2025 to 2031. New rules and new ideas help the market grow.

Oyang is a top company in this busy market. Their machines use smart automation and work very fast. Oyang’s machines can use different kinds of paper and designs. You do not need much training because the controls are easy to use. The machines always make good bags. This helps you trust the product and your customers trust you. Here is a table that compares Oyang’s machines with other brands:

| Feature | Oyang’s Machines | Competitors’ Machines |

| Automation | Makes production easier and fewer mistakes | Some are less automated |

| User-Friendly Interface | Easy to use, little training needed | Harder to use, needs more training |

| Precision Engineering | Uses less material, high quality | Quality and material use can change |

| Production Speed | Makes bags quickly for big orders | Usually slower |

| Flexibility | Works with many paper types and designs | Not as flexible |

| Consistency | Bags are always the same quality | Quality can change |

Oyang’s focus on new ideas and strong machines helps you keep up with changes in the market and what customers want.

Customization & Production Capacity

Machine Output & Size

When you pick a paper bag making machine, check how many bags it can make and how big it is. Machines that make more bags do the job faster. This helps you keep up with what people want. Bigger machines cost more because they can make more bags and have better features. The table below shows how fast each machine works and how size changes the price:

| Machine Type | Production Speed (pieces/min) | Size Impact on Price |

| Square Bottom Paper Bag Machine | 30-180 | Costs more because it makes more bags |

| V Sharp Bottom Paper Bag Machine | 50-320 | Costs more because it makes more bags |

| Simple V-shaped Bottom Machine | 400 | Costs more because it makes more bags |

| Fully Automatic Machine | 3000-6000 | Costs much more because it has special features |

If you want to make lots of bags, pick a machine that can handle big orders. This helps you stay ahead of other companies.

Oyang’s Custom Solutions

There are many ways to change paper bag making machines to fit your needs. You can pick options that help your business. Some choices are:

Adding things like handle units, printing modules, or smart monitoring systems costs more at first. But these upgrades help you make better bags and work faster. The table below shows how these changes affect the price:

| Customization Option | Impact on Pricing |

| Handle attachment units | Costs more but makes better bags |

| Multi-color printing modules | Costs more but makes better bags |

| IoT-enabled monitoring systems | Costs more but helps you work faster |

Oyang gives you custom machines for many needs. You can pick machines that match the size, shape, and look you want for your bags. For example, the Oyang B220 model makes 120–156 bags every minute. Some Oyang machines can make over 200,000 bags in one day. The Pro Model makes strong grocery bags that hold up to 5kg, which is twice as much as most bags. Oyang’s machines use automation, like automatic collecting and packing, to help you work faster and use fewer workers. These new ideas help you keep up with what customers want and help your business grow.

Tip: Changing your paper bag making machine helps you be different from other companies and meet special customer needs.

Regulatory & Environmental Pricing Drivers

Compliance Costs

It is important to know how rules change machine prices. Governments make strict rules for food safety and packaging. These rules help keep bags safe for food. You must follow health guidelines. The table below lists some main rules you need to follow:

| Compliance Requirement | Description |

| Food Additive Usage | Food additives must be less than 0.5% of the paper’s weight. |

| Coating Requirement | The food-contact side needs a coating at least 1/3-mil thick. |

| Functional Barrier | Treated paper must be separated from food by a special layer. |

| Labeling Requirement | Clear directions must be included for proper use. |

Machines that meet these rules cost more money. Following these rules can make the starting price go up by 10% to 20%. You also pay for safety features and better electrical parts. Upgrades help machines work better and safer. These costs help you avoid fines and keep your business safe. Buying machines that follow the rules protects your company from legal problems.

Tip: Always check new rules before buying machines. This helps you plan for extra costs and keeps your production safe.

Eco-Friendly Solutions

Many countries want companies to use eco-friendly packaging. Single-use plastics are banned in lots of places. The European Union and other regions want reusable paper bags. These rules make more companies buy green machines and try new ideas.

Manufacturers use new ways to lower costs and make more bags. The table below shows how these changes help your business:

| Cost Reduction Strategy | Impact on Production |

| Process optimization | Makes production costs 15% lower. |

| Economies of scale | Makes material costs 20% lower. |

| Advanced technology integration | Makes production 10% more efficient. |

You get machines that use kraft paper, recycled fibers, and biodegradable materials. These machines add coatings that keep bags dry and seams that are strong. Using green materials helps the planet and makes your business work better. Customers want strong bags that are good for the environment, so demand goes up.

Use kraft paper and recycled fibers for your bags.

Make bags with biodegradable materials.

Add coatings and strong seams for better bags.

Environmental rules make you pick machines that help the planet. You meet customer needs and help nature. Following these trends keeps your business strong and ready for the future.

Many things can change how much a paper bag making machine costs. The kind of machine you pick matters a lot. If the machine has automation, it works faster and saves money. Energy-saving machines help you spend less on power. Customization lets you make bags that fit special needs. The table below lists the main things to think about:

| Factor | Impact on Your Decision |

| Machine type | Changes price and output |

| Automation | Improves efficiency, lowers cost |

| Customization | Meets special production needs |

| Market trends | Guides your investment |

You should look at Oyang’s new and green machines. Think about what you need to make, what is popular, and the rules before you buy a paper bag making machine.

FAQ

What affects the price of a paper bag making machine most?

Raw material costs matter a lot. Automation level also changes the price. Machines that make more bags cost more. Extra features can make machines more expensive.

Can you customize a paper bag making machine for special bag sizes?

Yes, you can pick machines with adjustable settings. You can use different molds for bag shapes. Oyang has models for many bag sizes and shapes.

How much maintenance does a paper bag making machine need?

You should clean the machine often. Check the transmission parts for problems. Add oil to keep things moving well. Regular care helps the machine work better and last longer.

Are paper bag making machines eco-friendly?

Most new machines use biodegradable and recyclable materials. Oyang’s machines help you make bags that are good for the environment.

How fast can a paper bag making machine produce bags?

Production speed depends on the model you choose. Some Oyang machines make over 200,000 bags each day. Pick a machine that fits your business needs.