Oyang’s Roll Fed Paper Bag Making Machine is number one on the list for 2025. Other top machines are from Windmöller & Hölscher, Bobst Group, Zhejiang Xinlei, Profama, KIMATIC SRL, and ALLWELL. Choosing the best paper bag making machines helps your business get bigger and stay green. More companies want packaging that is good for the planet. Machines like Oyang’s help with this need. Reports say the market is growing fast:

The world Paper Bag Machines Market might reach USD 0.566 billion in 2025.

More people want eco-friendly packaging, and the market could be USD 498.29 billion by 2034.

Key Takeaways

Picking the right paper bag making machine helps you work faster and save money. New machines do many jobs by themselves, so you need fewer workers and make less waste.

Being eco-friendly is important. Machines that follow green rules bring in customers who like earth-friendly packaging. This helps your business get bigger.

Buying better machines lets companies make many kinds of bags fast. This helps you give customers what they want and makes your business stronger.

Think about what your business needs before you buy. Check how many bags you need to make, what materials you can use, and how much you can spend. This helps you pick the best machine.

Oyang is known for new ideas and helping customers. Their machines use less energy and are made to help your business do well as things change.

Why the Right Paper Bag Making Machine Matters

Production Efficiency and Cost Savings

Picking the right paper bag making machine can really help a business. Companies want machines that save money and work quickly. New machines do many jobs by themselves. Workers do not have to do as much by hand. This means businesses pay less for workers. They can also make more bags in less time. Modern machines use materials better, so there is not much waste. Buying all-in-one machines is smart for the future. These machines help companies change with the market and make more money.

| Evidence | Description |

| Investing in all-in-one bag making machine | Gives the best value over time. It helps companies keep up with what customers want and make more money. |

Buying better machines makes work faster and easier.

It helps save money and time.

To do well in this business, you need a good plan.

Good management and new machines help keep things running and costs low.

Sustainability and Eco-Friendly Packaging

The packaging world is choosing greener options. More people want things that do not hurt the planet. Paper bag making machines help companies do this. Machines that meet rules like FSC and ISO 14001 use less energy and safe materials. These labels show customers a company cares about nature.

| Certification | Description |

| FSC (Forest Stewardship Council) | Makes sure paper comes from safe forests. This is good for people who care about the planet. |

| ISO 9001 | Shows the company makes good products every time. |

| ISO 14001 | Helps companies make less waste and use less energy. |

| ISO 45001 | Makes sure workers are safe at their jobs. |

| ISO 22000 | Keeps food safe in paper bags for food. |

| ISO 50001 | Helps companies use energy better. |

| ISO 20400 | Teaches companies to buy things in a green way. |

![Bar chart showing consumer loyalty and sales statistics related to sustainable packaging]()

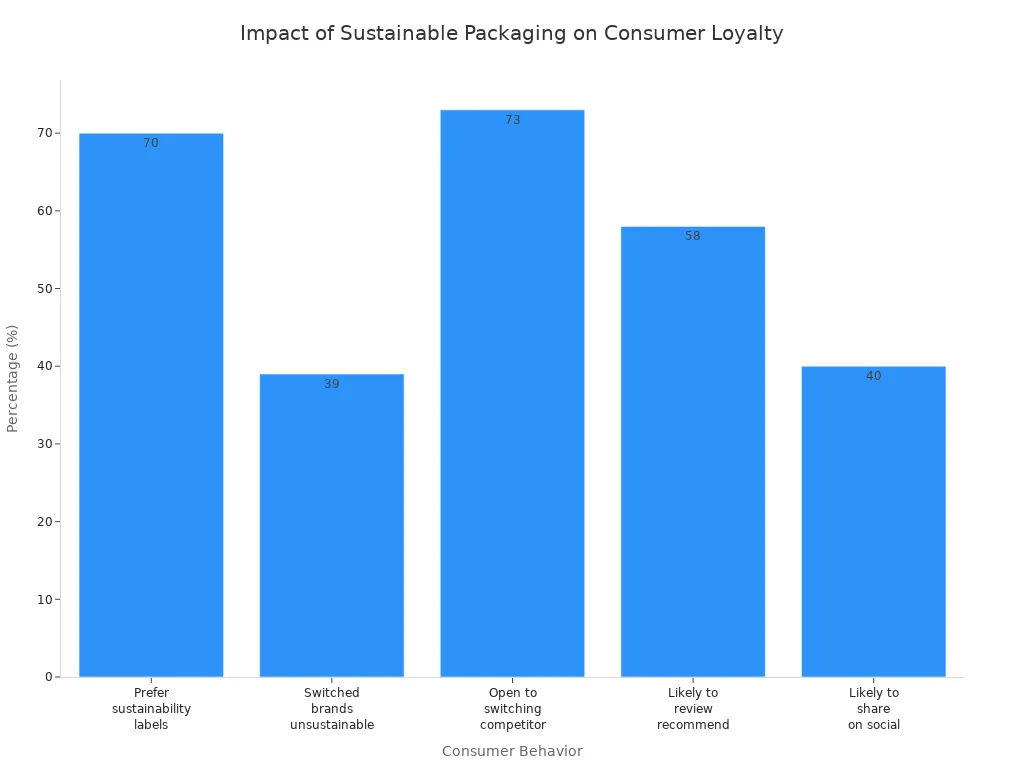

Studies show that using green packaging can make more money each week. Many people like to buy things with green labels. Some will even pick a new brand if the packaging is not good for the planet.

Impact on Business Growth

Paper bag making machines help companies get bigger. Machines that do more work mean fewer mistakes and lower costs. Companies can make more bags and change faster when needed. Buying the right machines lets companies make more products. The packaging world likes companies that use smart machines and follow new trends. Picking the best machine helps a business grow and find new customers.

Machines that do more work help companies make more bags, save money, and grow faster.

Buying the right machines helps companies make more things and need fewer workers.

Top 7 Paper Bag Making Machines for 2025

Picking the right paper bag making machines is important for any business. There are many choices, but some machines are better because they are fast and make good bags. Some machines also have smart features that help a lot. Here are the top seven machines that experts say are best for 2025. Each machine has something special to offer.

Quick Look:

The table below shows the top suppliers and what makes their machines stand out.

| Rank | Supplier Name | Key Features |

| 1 | Zhejiang Xinlei Machinery Co., Ltd. | Advanced technology, customization, energy-efficient machines |

| 2 | Windmöller & Hölscher | High-precision engineering, automation, innovative printing technology |

| 3 | Bobst Group | Sustainable design, versatile production, advanced quality control |

| 4 | Jagenberg Converting Technologies | Robust construction, flexible production, advanced gluing and sealing technology |

| 5 | Langston Corporation | Printing excellence, high-speed production, user-friendly interface |

| 6 | KOPP Maschinenbau GmbH | Innovative design concepts, modular construction, low noise operation |

| 7 | Shandong Dongtai Machinery Co., Ltd. | Wide range of machines at competitive prices |

Let’s look at each machine and see why it is a top choice.

Oyang Roll Fed Paper Bag Making Machine

Oyang’s Roll Fed Paper Bag Making Machine is the top pick for 2025. This machine is very fast and has a smart design. It can make over 200,000 paper bags each day. This helps businesses fill big orders. The machine works almost by itself, so workers do not need to do much. This saves both time and money.

Oyang uses a servo-electric control system from Japan. This system helps the machine run well and makes sure every bag looks the same. The machine can make many kinds of bags, like food bags, shopping bags, and bags with special handles or shapes. Oyang cares about the planet, so the machine uses less energy and helps companies reach green goals.

Main Advantages:

Makes lots of bags every day

Works by itself with little help

Makes bags that all look the same

Can make many types of bags

Good for green packaging

| Feature/Advantage | Description |

| High Efficiency | Makes more than 200,000 bags per day |

| Automation | Runs with little help from workers |

| Precision | Uses advanced controls for accurate results |

| Versatility | Handles many bag styles and sizes |

| Environmentally Friendly | Helps companies offer green packaging |

Oyang’s machine helps businesses save money, make more bags, and meet the need for eco-friendly paper bag making machines.

Windmöller & Hölscher Paper Bag Machine

Windmöller & Hölscher is a famous name in paper bag making machines. Their machine uses high-precision engineering and smart automation. It can make block bottom SOS bags with flat handles. The machine can make bags from 105 to 320 mm wide and bottoms from 55 to 180 mm wide. It also has a jumbo roll unwind system and automatic web tension control.

Some cool things are a hydraulic reel lift and a pneumatic unwind shaft. The servo motor keeps the machine at the right speed. This machine is great for businesses that want fast, steady work and modern printing.

Bobst Group Square Bottom Paper Bag Machine

Bobst Group’s Square Bottom Paper Bag Machine is known for quality and being reliable. It can use different paper types and make many kinds of bags. The machine checks each step to make sure every bag is good. The controls are easy to use and it is simple to keep clean.

Bobst is known for great support and has help all over the world. This means help is always close if a business needs it. Companies trust Bobst because their machines last a long time and work well.

| Feature | Description |

| Versatile Functionality | Makes many types of bags from different papers |

| Quality Control | Checks each bag for defects |

| Easy to Use | Simple controls and easy maintenance |

| Trusted Brand | Known for strong support and reliable machines |

Zhejiang Xinlei Machinery Co., Ltd. Paper Bag Machine

Zhejiang Xinlei makes paper bag machines with advanced technology and lots of ways to change them. Their XL-ZD330 and XL-ZD450 models can make bags from 120 mm to 450 mm wide. The machines can run up to 220 pieces each minute. They use energy well and can work with thick or thin paper.

Customers like these machines because they are easy to use and adjust. Businesses can pick the size and speed they need. This helps companies grow and meet what customers want.

Profama SOS 030-CE Paper Bag Machine

Profama’s SOS 030-CE machine is good for making self-opening square (SOS) paper bags. It is strong and works smoothly. The machine can make bags fast and does not waste much. It can also make different bag sizes, which is good for businesses that need to change products.

Profama makes machines that are easy to use and keep working. This helps companies keep making bags without stopping for long. The machine’s design also helps save on energy.

KIMATIC SRL High-Speed Paper Bag Machine

KIMATIC SRL makes high-speed paper bag machines for busy factories. Their machines can make lots of bags quickly. They use smart automation to keep things running well. The machines also have safety features to keep workers safe.

KIMATIC’s machines are made to last. They can work for long hours and handle a lot of use. This makes them a good buy for companies that want to grow and fill big orders.

ALLWELL Flat & Handle Paper Bag Machine

ALLWELL’s Flat & Handle Paper Bag Machine is great for making many kinds of bags. It can make bags from 180 mm to 600 mm long. The machine works with many paper types and can add different handles. Businesses can also print their logos or designs on the bags.

Did you know?

ALLWELL’s machine lets companies make bags that match their brand. This helps products get noticed in stores.

Makes bags in many sizes and styles

Bag lengths can be changed for different products

Works with many paper types

Custom handle choices

Printing for company logos

ALLWELL’s machine is a good choice for companies that want to make special bags that look great.

These top paper bag making machines help businesses stay ahead in a fast-changing market. Each machine has its own strengths, like making bags fast, being good for the planet, or being easy to change. Picking the right one can help a company save money, work faster, and meet the need for green packaging.

Key Features of Paper Bag Making Machines

Production Speed and Capacity

How fast a machine works is very important. Companies want machines that make bags quickly. This helps them finish big orders on time. Most paper bag making machines can make 300 to 9,000 bags every hour. Some machines can make up to 400 bags each minute. Oyang’s Roll Fed Paper Bag Making Machine makes over 200,000 bags in one day. Fast machines help businesses grow and keep customers happy.

| Capacity Range | Production Speed |

| 300 - 9,000 pcs/hr | Varies by model |

| 100 - 400 bags/min | Shopping Bag Machines |

| 200,000 bags/day | Oyang Roll Fed Machine |

Automation and Control Systems

Automation makes bag making easier for companies. Automated machines use digital controls and sensors to work well. These systems cut and fold paper with great care. They find mistakes fast and fix them right away. Oyang’s machine uses a servo-electric control system from Japan. This helps the machine stay fast and accurate. Automation saves energy and lowers costs. Companies can make more bags without hiring more workers.

High-speed machines make more bags.

Quality control finds problems quickly.

Energy-saving cycles use less power.

Machines can handle bigger orders easily.

Bag Size and Type Flexibility

Modern machines can make many types of bags. Some machines make square-bottom bags for stores. Others make pointed or flat-bottom bags for special uses. There are different handle styles like twisted, flat, or ribbon. Oyang’s machine lets users change settings for different bag sizes and shapes. This helps companies meet customer needs and try new ideas.

Square-bottom bags are good for shops.

Pointed and flat-bottom bags look nice.

Different handles add style and comfort.

Energy Efficiency and Maintenance

Using less energy and easy care saves money. Machines with smart cycles use less electricity. Oyang’s machine is built to use less energy and run smoothly. Cleaning and checking the machine often keeps it working well. Less downtime means more bags get made. Companies spend less on repairs and power.

Energy-saving machines lower bills.

Easy care keeps machines working.

Less waste is better for the planet.

Printing and Customization Options

Printing and custom choices make bags special. New technology lets machines print bright colors and logos. Oyang’s machine can do digital printing for small orders. Companies can choose bag sizes, handle types, and how the bag looks. Machines use green paper and cut special shapes with care.

| Feature | Description |

| Multi-color printing | Bright, clear designs |

| Custom bag sizes | Fits many products |

| Handle choices | Twisted, flat, ribbon |

| Eco-friendly options | Uses green materials |

| Precision die-cutting | Makes special shapes |

Paper bag making machines with these features help businesses do well. They work fast, save energy, and let companies make bags in many ways.

How to Choose the Best Paper Bag Making Machine

Assessing Your Business Needs

Every business needs something different. Some companies make lots of bags each day. Others want bags in special shapes or sizes. Before buying, they should think about how many bags they need. They should also think about what kinds of bags they want. Companies check if the machine works with their paper. They want a machine that fits their work and helps them grow.

Tip: Write down your most important needs before shopping.

Key factors to consider:

Production capacity

Material compatibility

Cost of the machine

Impact on efficiency

| Factor | Description |

| Production Capacity | How many bags the machine can make in a set time |

| Bag Size and Variety | What sizes and styles the machine can produce |

| Machine Durability | How long the machine lasts and how often it needs care |

| Energy Efficiency | How much power the machine uses |

| Environmental Impact | How green the machine and its products are |

Budget and Investment Considerations

Money is important when buying paper bag making machines. Prices change if the machine has more features or is bigger. Some machines cost $20,000. Some cost up to $500,000. Companies look at their budget and think about how fast the machine will pay for itself. Many companies use payment plans or leases to help with costs.

| Type of Machine | Cost Range |

| Fully Automatic | $20,000 - $150,000 |

| Sheet Fed | $10,000 - $500,000 |

| Premium Machines | $50,000 - $500,000 |

Note: Some companies use bank loans, equipment financing, or government grants to help pay.

Manufacturer Reputation and Support

A good company makes strong machines and helps customers. Trusted brands give better support and good parts. They help keep machines working longer. Oyang is known for helping customers and giving reliable service. Working with a trusted supplier means less downtime and fewer problems.

High-quality machines last longer.

Good support means fast help and easy repairs.

Trusted suppliers offer strong replacement parts.

After-Sales Service and Warranty

After buying, companies want help if something breaks. Most paper bag making machines come with a warranty. This covers parts and labor for a set time. Some brands offer 24/7 support and remote help. Companies should check what the warranty covers and how to get help.

| Warranty Coverage | Exclusions | Support Options |

| Covers parts and labor | Normal wear, misuse, changes | 24/7 tech support, remote assistance |

Tip: Always ask about service and warranty before picking the best machine.

Why Choose Oyang for Paper Bag Making Machines

Oyang’s Innovation and Sustainability

Oyang is different because it always tries new ideas. The company cares about the planet and uses green designs. Oyang’s machines can make many kinds of bags. These include snack bags, bread bags, and eco-friendly bags for big brands like KFC and McDonald’s. The machines work quickly and do not use much power. This means less waste and lower energy bills. Here are some things that make Oyang’s machines special:

| Feature | Description |

| Bag Variety | Snack, food, bread, dry fruit, and eco-friendly bags |

| Efficiency | High efficiency and stable operation |

| Paper Thickness | Handles 30-100 GSM |

| Speed | 150-500 pieces per minute |

| Power | 16KW, energy-saving |

| Double Channel | Double capacity, low power use |

| Best For | Food bags like bread, KFC, and McDonald’s bags |

Oyang helps companies use green packaging. This is important because more people want eco-friendly bags.

Advanced Technology and User-Oriented Service

Oyang uses new technology to make sure its machines work well. The machines have smart controls that are easy to use. Users can change settings fast to make different bags. Oyang’s team listens to customers and helps them at every step. If a business wants to try something new, Oyang helps them find the best way. The company always gives support when needed.

Tip: Oyang’s machines are simple to use, even for beginners.

Global Achievements and Customer Support

Oyang is a top company for paper bag making machines. It has more than 85% of the world market. Oyang works with almost 10,000 customers in over 170 countries. Many people say Oyang’s service is helpful and the machines are strong. Oyang’s non-woven bag making machines are used by most companies around the world. This shows that many businesses trust Oyang.

Oyang helps customers in over 120 countries.

The company puts customers first and keeps them happy.

Oyang’s machines help businesses grow and do well.

Oyang is a smart pick for any business that wants a good paper bag machine. It uses new ideas, strong technology, and gives great support.

Picking the best paper bag making machines helps your business grow. Oyang makes machines that save energy and help the planet. Every company should pick machines that fit their needs. This helps them do well for a long time. Here are some easy tips:

Make good bags for many stores.

Give cheap packaging for people who want to save money.

Know your costs and plan when you will make a profit.

Buy more than one machine if you want to sell overseas.

Learn about rules for trading with other countries.

Make strong teams with your sellers.

Need help from experts? Go to Oyang’s website or talk to their team for advice.

FAQ

How many paper bags can a machine make in one day?

Most machines make thousands of bags daily. Oyang’s Roll Fed Paper Bag Making Machine can produce over 200,000 bags every day. That helps businesses fill big orders fast.

Can these machines make bags in different sizes and shapes?

Yes! Many machines, including Oyang’s, let users adjust settings for special sizes and shapes. Companies can create bags for food, shopping, or gifts.

What kind of paper works best for these machines?

Most machines use kraft paper, coated paper, or recycled paper. Oyang’s machine handles paper from 30 to 100 GSM. That gives companies lots of choices for eco-friendly bags.

Tip: Always check the paper type before starting a new batch.

Is it hard to keep a paper bag making machine running well?

Not really. Regular cleaning and checking moving parts help a lot. Oyang’s machines need simple care, like adding oil and checking belts. That keeps production smooth.

| Maintenance Task | How Often? |

| Clean machine | Weekly |

| Check belts | Monthly |

| Add lubricating oil | As needed |