Product Description

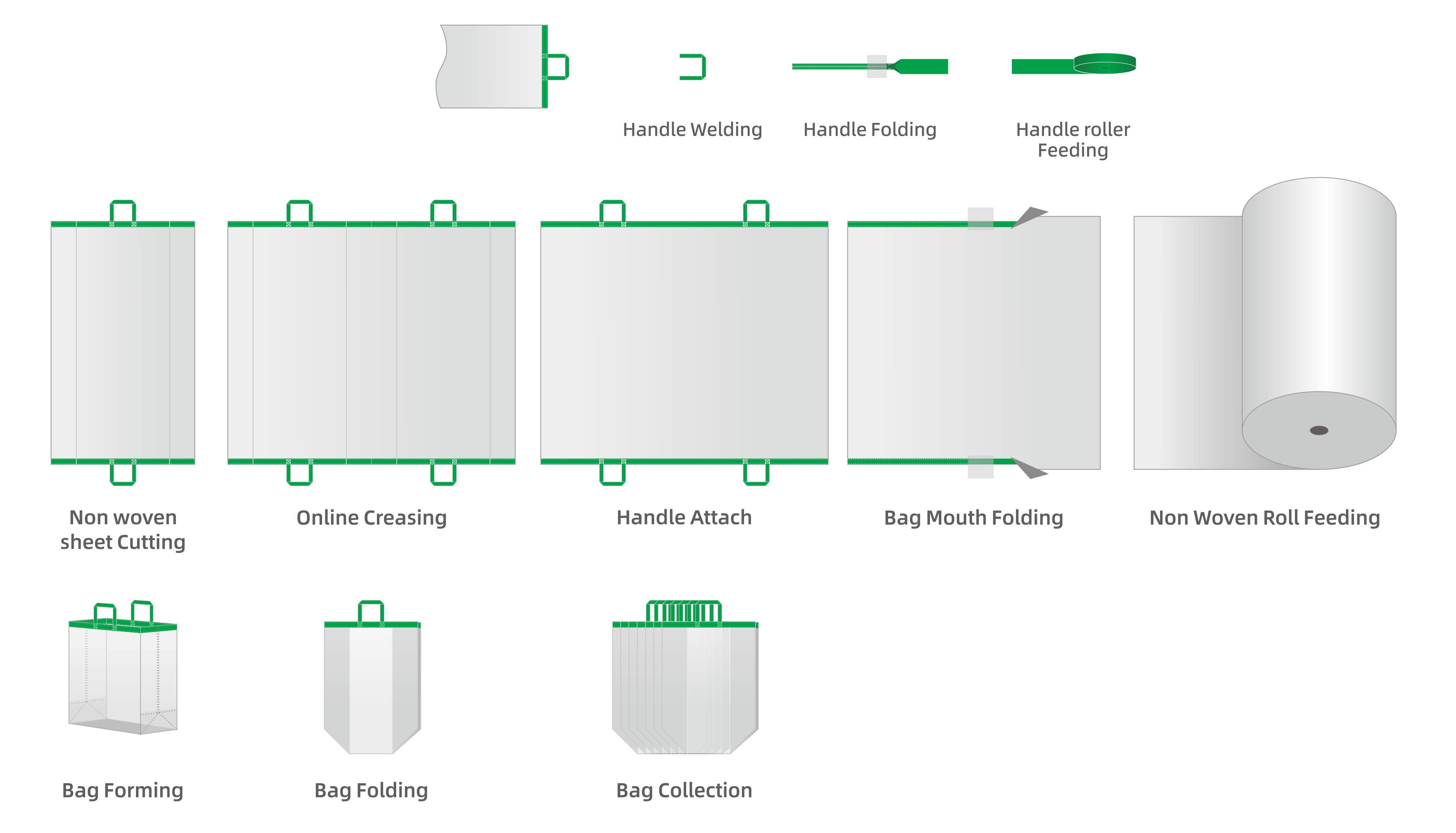

Leader Non Woven Box Bag Machine is a world first set 3D one time forming machine, which start to developed since

2009 and successfully coming at October 2013 year, Youtube and Facebook have all records!

Till now, it has obtained 12 invention patents and more than 30+ new-use patents. More than 1000+ customers have been using our equipment in China domestic market, and exported to more than 120+ countries, accounting for more than 90% of the market sales share of this equipment.

This machine is designed for peritoneal non-woven fabric and pure non-woven fabric molding, can replace the traditional sewing more than 200 people, rapid mold change 20 minutes, the equipment operation is efficient, stable, mass used intakeaway food, tea, wine, beverage, clothing footwear, gift advertising packaging!

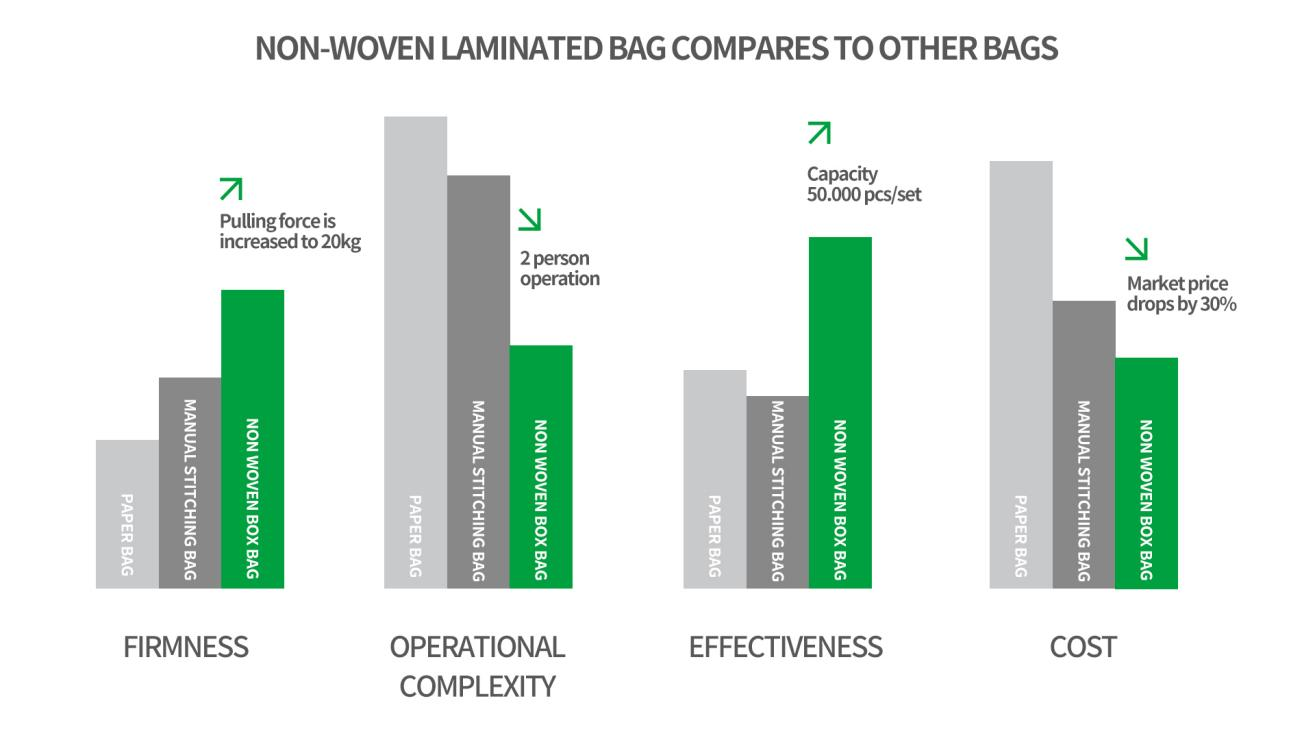

Advantage

The machine is dedicated to the production of non-woven box bags withlamination and non-laminationn, one-time forming of box bags, automaticbag taking, automatic bundling, reguiringfewer workers, high efficiency,and low production cost. lt is the most competitive equipment in the marketfor producing non-woven box bags.

Featuring the following five major advantages:

High-Speed & Stable Operation: Achieves 80-90 bags per minute, with a daily output capacity of up to 100,000 bags, significantly boosting production efficiency.

Fully Automated Handling & Strapping: Equipped with an automatic robotic arm for bag pickup and integrated strapping function. Saves 2 sorting workers per day, reducing direct labor costs by approximately $26,000 annually.

Vision-Based Automatic Inspection: Detects defects including missing or broken handles, inadequate side seam strength, and improper adhesive tape application. Automatically rejects defective bags to ensure high yield rates.

Precision Automatic Alignment: Ensures handles are automatically centered, bag openings are aligned, and handle spacing or length are automatically adjusted.

Indirect Adhesive Application: Saves $0.001 per bag on adhesive costs, reducing your annual expenses by $11,500 - $14,300.

PP non woven lamination material requirement

PP non woven (pp melt index 20 ,the calendar temperature 170-180)

Lamination material

PP:PE =4:1 Opp thickness should be 0.015mm-0.018mm

PP melt thickness 10-15gsm

Opp should be shining opp,both side with corona

![laminated bag laminated bag]()

Remark: Leader can perform good with few labour, higher efficient & lower cost, it’s the most competitive machine in non woven bag making.

Bag Type

Shopping Bag, Clothing Bag, Food Bag, Gift Bag, Take Away Bag