The Ultimate Guide to Flexible Packaging Pouch Types: Smart Packaging Starts with the Right Structure

1. Industry Overview — Flexible Packaging Is Booming, and Pouch Style Shapes Brand Identity

From 2024 to 2025, the global flexible packaging market continues to grow rapidly. According to Fortune Business Insights, the global market value of flexible plastic packaging reached USD 157.74 billion in 2024, is expected to grow to USD 166.53 billion in 2025, and will surpass USD 250.3 billion by 2032, with a compound annual growth rate of approximately 6%.

At the same time, technologies such as biodegradable materials, smart labels, and high-barrier coatings are maturing rapidly. Consumers are demanding more sustainable and efficient packaging, driving the flexible packaging industry into a new phase of innovation and structure upgrading.

In this context, understanding the features and applications of various pouch styles helps brands and manufacturers select the right pouch, upgrade their packaging, and enhance their market competitiveness.

2. Six Core Pouch Types — Structure, Function & Application at a Glance

(1) Three-side Seal Pouch

Structure: Sealed on three sides, with one open edge for filling. Compact and efficient.

Applications: Candy, seasoning powder, sample sachets, granules, etc.

Popular Variants:

Spout pouch: With a reclosable nozzle, ideal for liquids like detergents and beverages

(Hang hole pouch: With a hole at the top for display hooks

Easy-tear pouch: For one-time use, common in pharmaceuticals and snacks

(2)Stand-up Pouch

Structure: With bottom gussets allowing the pouch to stand upright after filling. Great for shelf display.

Applications: Nuts, dried fruit, sauces, pet snacks, detergent pods, etc.

Popular Variants:

Zipper pouch: Reclosable and user-friendly

Spouted pouch: With a top spout, commonly used for juices, baby food

Hang tab pouch: With a hanging hole for retail display

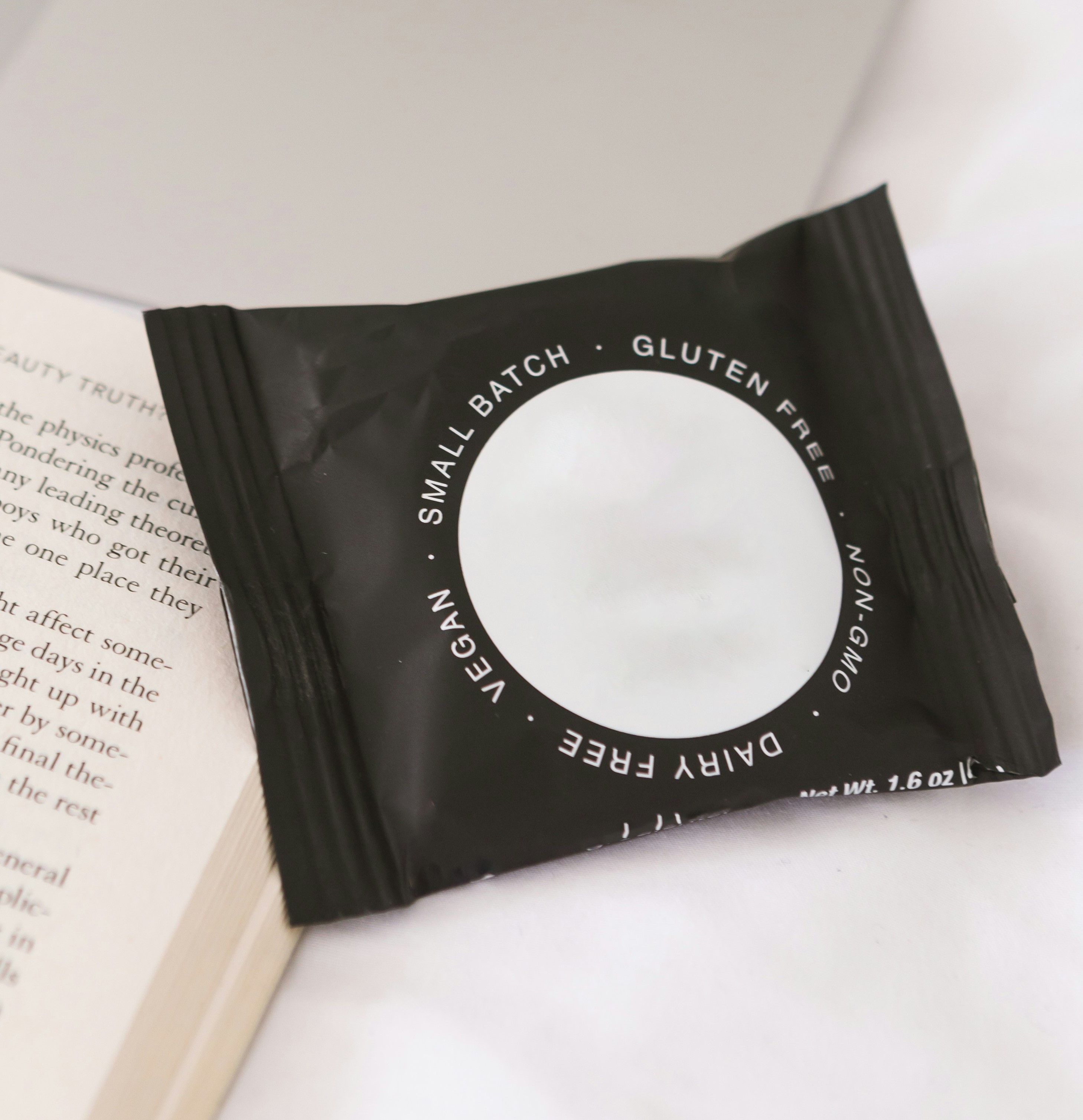

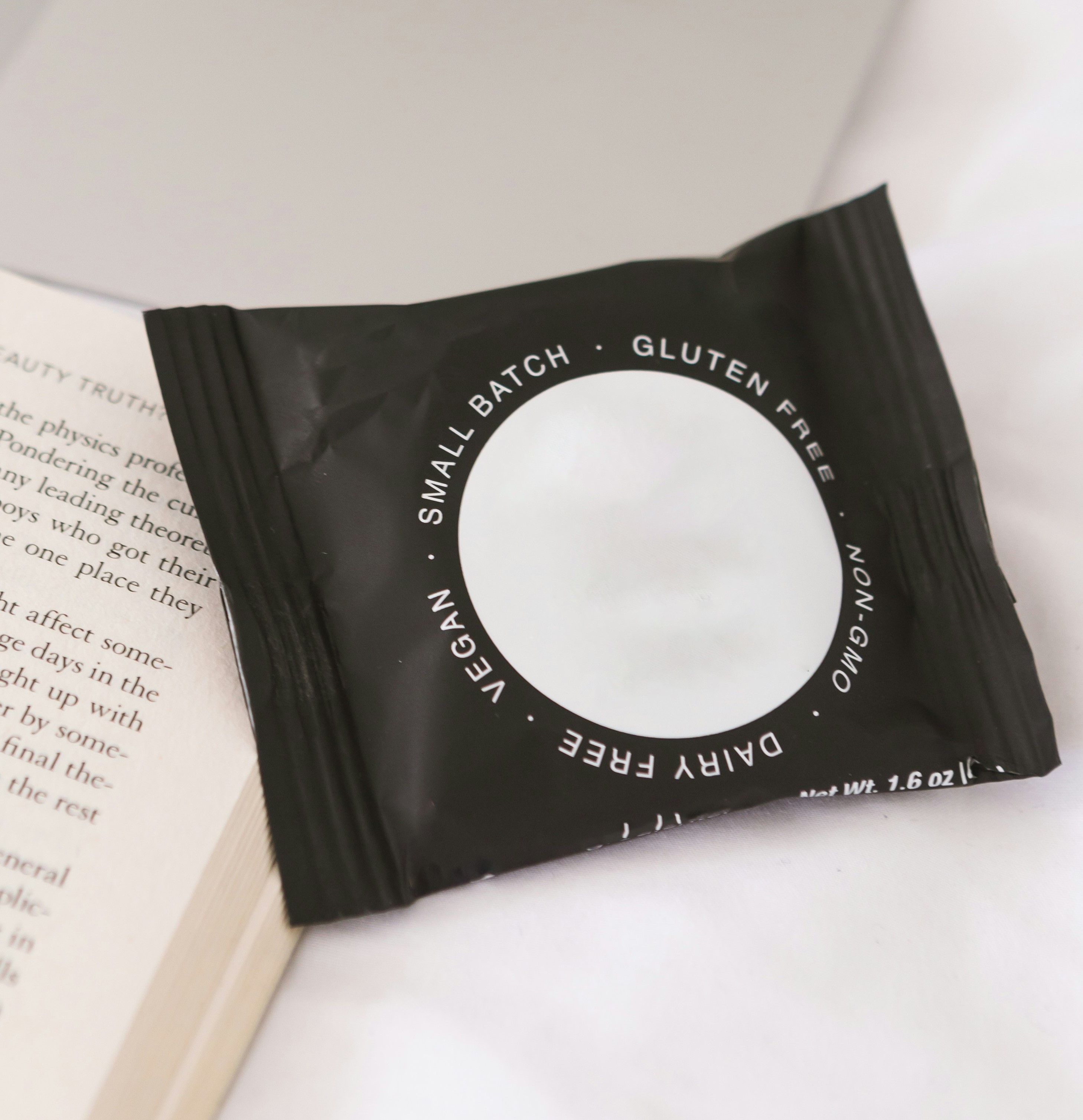

(3) Four-side Seal Pouch

Structure: Sealed on all four sides, flat and neatly shaped, ideal for flat content.

Applications: Pharmaceuticals, face masks, supplement powder, cosmetics.

Popular Variants:

Twin-chamber pouch: Two compartments for mixing before use

Aluminum foil pouch: High barrier, great for oxygen-sensitive products like tea and desiccants

(4)Center Seal Pouch

Structure: Sealed vertically along the back, with top and bottom horizontal seals. Compatible with roll film and continuous packaging.

Applications: Candy, dry foods, pet food, sauce sachets.

Popular Variants:

Chain pouch: Connected small pouches, tear-off design

Easy-tear pouch: Added notch for easier opening

(5)Center Seal Gusseted Pouch

Structure: Adds side gussets to the center seal pouch, increasing internal volume.

Applications: Flour, coffee beans, large pet food, grains.

Popular Variants:

Double gusset pouch: Enhanced stability and capacity

Handle pouch: With handles for easy carrying of larger sizes (e.g., 5kg bags)

(6)Flat Bottom Pouch

Structure: Eight sealed edges (4 bottom + 2 on each side), with a self-standing base. A premium, structured look.

Applications: Premium pet food, functional snacks, coffee, supplements.

Popular Variants:

Zipper pouch: Resealable with elegant shape

Degassing valve pouch: Allows gas release, ideal for freshly roasted coffee beans

Window pouch: Transparent section to showcase product contents

3. Functional & Custom Pouch Types — Special Structures, Specific Needs

(1)Shaped Pouch

Custom die-cut shapes aligned with brand identity or target audience appeal.

→ Common in beverages, kids' snacks, personal care samples

(2)Bone Pouch

Enhanced sealing strength for medical, frozen, or electronic packaging

(3)Matt & Glossy Pouch

Mixed surface textures for a premium contrast effect

(4)Vacuum Pouch

Ideal for oxygen-sensitive products like cured meat, cooked foods, dried goods

(5)Stand-up Handle Pouch

Includes reinforced handles for large-format, refill, or gift packaging

4. Final Thoughts — The Right Pouch Creates a Powerful Brand Experience

Choosing the right pouch type not only enhances product value but also optimizes production efficiency. At Oyang Machinery, we specialize in flexible packaging equipment and offer customized solutions for a wide range of pouch structures — from standard to shaped and multifunctional pouches.

Looking for pouch samples, tailored suggestions, or a complete packaging line setup?

Contact us today to start your custom flexible packaging journey.