Leading paper bag suppliers sell machines for sustainable packaging. KIMATIC SRL, DP Machines, Mohindra Engineering Company, and COSMO Machinery have advanced paper bag making machine models. The price depends on automation, quality, and how many bags the machine can make. New trends show people want eco-friendly and energy-saving machines. Laws banning single-use plastics make more people buy these machines and raise prices. Buyers should look at features and value to pick the best machine for what they need.

Key Takeaways

Pick suppliers known for good quality and help. Well-known brands usually give better machines and service.

Think about how much the machine does by itself. Machines that work automatically save time and need fewer workers. These machines cost more money.

Check how many bags the machine can make. Machines that make more bags save time and money later.

Find out if there is help after you buy and if there is a warranty. Good help keeps the machine working well and stops long breaks.

Look at prices and features from many suppliers. This helps you get the most for your money.

Leading Paper Bag Suppliers

KETE Group Limited

KETE Group Limited is a top paper bag supplier. They focus on automatic machines and green packaging. The company sells flat and satchel paper bag making machines. These machines have CE and RoHS certificates. KETE’s main model is the Fully Automatic Paper Shopping Bag Making Machine. This machine makes square bottom paper bags with flat handles. It uses good parts from brands like SCHEIDER and LENZE. KETE has good prices, but the cost changes by machine type. Buyers like the company’s quality and trust their packaging.

Tip: KETE machines are great for businesses that want automatic and certified packaging.

NEWLONG

NEWLONG is a top paper bag supplier with strong technical skills. They give automatic paper bag making machines. NEWLONG helps before you buy and after you buy. They give a one-year warranty for all machines. Their machines come with training and help at your place. The price shows their good support and quality. Many buyers pick NEWLONG for good packaging and fast service.

| Unique Selling Points | Warranty Terms |

| Pre-sales Technical Consulting | One-year warranty for machines ordered. |

| Technical Guidance & Support | Lifetime after-sales service. |

| Machine Upgrading |

|

| Machines Demo & Operators Training |

|

| Services On Worn And Spare Parts |

|

| After-sales Service System |

|

| At-site Installation |

|

| 24-hour Response |

|

Holweg Weber

Holweg Weber has been a top paper bag supplier for many years. They make automatic machines for fast packaging. Their main models are the 800/800W Series and RS 1500. The 800/800W Series is for fast food and makes many bags quickly. The RS 1500 is the fastest flat bottom bag making machine. It can make up to 3,000 bags each minute. Holweg Weber machines are easy to fix and safe to use. The price matches the speed and quality. Big companies like these machines for large packaging jobs.

| Model | Description | Key Features |

| 800/800W Series | Made for fast food, high output for packaging. | Best for fast food, strong, makes bags fast. |

| RS 1500 | Fastest flat bottom bag making machine, makes 3000 bags per minute. | Easy to fix, safe, easy to use screen. |

Dreampac Machines

Dreampac Machines helps small businesses with packaging. They sell automatic paper bag making machines with motors that save energy. Their machines make 40-60 bags every hour. They use a 3.7 kW motor to work well. Dreampac Machines are easy to use and fix. They help with setup and fixing problems. The price is low, so small companies like them.

| Feature/Support Option | Description |

| Production Rate | 40-60 bags per hour |

| Motor Efficiency | Uses 3.7 kW energy-saving motor |

| Target Audience | Good for small businesses |

| After-Sales Support | Simple controls for easy use and fixing |

MTD Pack

MTD Pack is known as a top paper bag supplier. They make automatic machines and new packaging ideas. Their machines work fast and can be changed for different needs. MTD Pack machines make many types of bags, like flat bottom and square bottom. The price depends on how fast and automatic the machine is. Buyers like the quality and choices MTD Pack gives.

Zhejiang Ounuo Machinery

Zhejiang Ounuo Machinery sells automatic paper bag making machines for many uses. Their machines have smart features like remote checks and AI quality control. Zhejiang Ounuo machines make flat bottom, SOS, and square bottom bags. The price goes from basic to fancy machines. Customers pick Zhejiang Ounuo for their smart tech and good packaging.

| Machine Model | Production Speed | Bag Types | Key Features |

| EcoBasic 100 | 60-100 bags/min | Flat bottom | Saves energy, small size |

| ProPack 200 | 100-200 bags/min | Flat bottom, SOS | Quick to change, makes many sizes |

| UltraFlex 300 | 200-300 bags/min | Flat bottom, SOS, Square bottom | AI checks quality, remote help |

| CustomCraft X | Varies | All types, even gusseted | Can be changed, works with Industry 4.0 |

Feather Touch Tissues (FTC)

Feather Touch Tissues (FTC) is a top paper bag supplier with cheap automatic machines. FTC has models that work fast and use little power. Their machines are good for businesses that want to save money. FTC gives warranties and helps after you buy. The price is low, so many buyers trust FTC for good machines.

Sahil Graphics

Sahil Graphics is a top paper bag supplier with fully automatic machines. They check quality very carefully. The company has good prices and a skilled team trained in India and China. Sahil Graphics helps customers from start to finish. Their machines use good materials and are trusted by many businesses.

| Feature/Advantage | Sahil Graphics Machines | Other Suppliers |

| Type of Machines | Fully automatic paper bag making machines | Varies |

| Focus on Quality | Checks quality and materials | Varies |

| Pricing | Good prices | Often higher |

| Technical Expertise | Skilled team from India and China | Varies |

| Customer Service | Helps from start to finish | Varies |

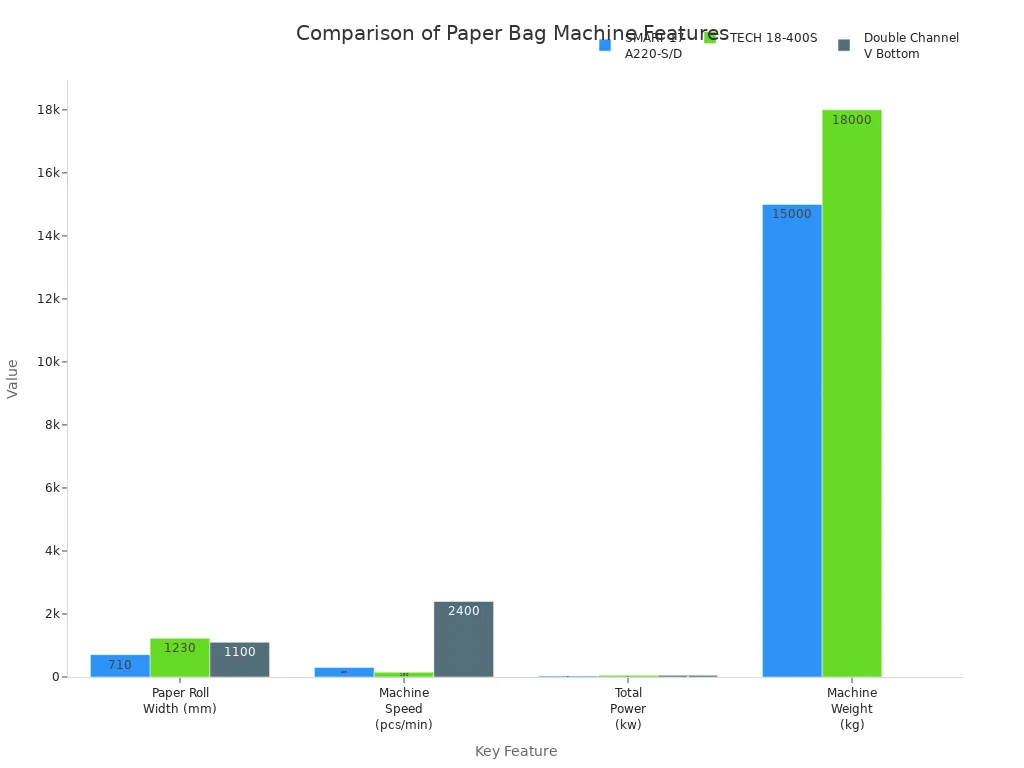

![Bar chart comparing paper bag machine speed, power, weight, and roll width for three suppliers]()

Note: Top paper bag suppliers have many automatic machines for packaging. Buyers should check price, quality, and help before picking the best machine.

Paper Bag Making Machine Price Comparison

Manual vs. Automatic Machines

People can pick manual, semi-automatic, or fully automatic machines. Manual machines need people to do most of the work. Semi-automatic machines use some automation but still need help from people. Fully automatic machines work almost by themselves and are much faster. Manual and semi-automatic machines cost less, so they are good for small businesses with less money. Fully automatic machines cost more, but they save time and need fewer workers.

| Type of Machine | Description | Cost Range |

| Semi-automatic | Needs manual work | $5,000 - $20,000 |

| Fully automatic | Runs with minimal human help | $20,000 - $150,000 |

Semi-automatic machines help companies start for less money. Fully automatic machines are better for big companies that want to make bags quickly and with better quality. The price difference shows that more automation makes machines cost more.

Tip: Buyers should think about their money and packaging needs before picking a machine.

Square Bottom vs. V-Bottom Machines

Square bottom machines and V-bottom machines make different kinds of bags. Square bottom machines make bags that stand up and look tidy. V-bottom machines make bags with a pointed bottom, which is good for fast packing.

| Feature | Square Bottom Machines | V Bottom Machines |

| Price | Generally more expensive | Generally cheaper |

| Production Speed | Slower due to complex processes | Faster, suitable for high volume |

| Material Usage | Requires more paper, higher cost | Uses less paper, more economical |

Square bottom machine: About Rs 80,00,000 each

V-bottom machine: About Rs 10,50,000 each

Square bottom machine: Makes 80-100 bags per hour

V-bottom machine: Makes over 1000 bags per hour

Square bottom machines cost more because they use more paper and work slower. V-bottom machines are cheaper and make bags faster, so they are good for making lots of bags. Buyers should look at both price and speed before choosing.

Price Range Overview

The price of paper bag making machines changes by model, speed, and how automatic they are. Entry-level fully automatic machines are cheaper but work slower. Mid-range machines are faster and have more features. High-end fully automatic machines cost the most and work the fastest.

| Model Type | Production Speed (bags/min) | Price Range (RMB) |

| Entry-level fully automatic | 30-50 | 100,000 - 200,000 |

| Mid-range fully automatic | 50-100 | 200,000 - 500,000 |

| High-end fully automatic | >100 | Over 500,000 (up to 1,000,000) |

The cheapest machines start at $5,000 for semi-automatic models. The most expensive automatic machines can cost $120,000 or more. Buyers should compare prices and how fast the machines work to find the best one for their needs.

Value for Money

Getting good value means looking at price, quality, automation, and support after buying. Buyers should check the warranty and service when picking a supplier. Some suppliers give longer warranties and better help, which is worth more.

| Supplier | After-Sales Support | Warranty |

| Wenzhou Rokin Machinery | 2-year warranty, remote diagnostics | 2 years |

| Wenzhou Tianyue Machinery | Training included | 1.5 years |

| Ruian Lilin Machinery | Manual English guides | 1 year |

A longer warranty and good support help buyers save money later. High-quality machines with strong support are a better deal, even if they cost more. Buyers should look at price, automation, and support before choosing.

Note: Buyers who want good packaging should compare price, cost, and quality from different suppliers. Picking the right machine for your money and needs gives the best value.

Factors Affecting Paper Bag Making Machine Cost

Machine Type and Features

The kind of machine changes how much it costs. Basic models like semi-automatic machines cost less and have fewer features. Fully automatic machines have things like touch screens and remote checks. They make bags faster and use better parts. These machines are more reliable and last longer. Sahil Graphics sells fast machines that help the environment. These cost more but are better for eco-friendly packaging. FTC has cheaper automatic machines for small businesses. Buyers should look at features, quality, and how green the machine is before picking one.

Production Capacity

How many bags a machine can make affects its price. Machines that make more bags save time. Suppliers with big factories and advanced machines charge more. This is because their machines work better and break less. The table below shows how making more bags changes the price:

| Supplier Characteristics | Impact on Pricing |

| Higher production capacity | Lower prices because making more bags saves money |

| Larger factory areas | Higher prices for better machines |

| Advanced automatic machinery | Less downtime, works faster |

Automation Level

Machines can be semi-automatic or fully automatic. Fully automatic machines cost more than semi-automatic ones. Automatic machines need fewer workers and make bags faster. Fully automatic machines can cost 30%-50% more. Big companies buy these for better quality and speed. Semi-automatic machines are cheaper but need more people to run them. Automatic machines help companies make eco-friendly bags.

Customization Options

Changing machine features can make them cost more. Suppliers talk to buyers to learn what they need. They check what the buyer wants and design special machines. They test the machines to make sure they work well. Buyers get training and help after buying. Custom machines cost more but fit the buyer’s needs. Good automatic machines with custom features help make eco-friendly bags.

Supplier Reputation

A supplier’s reputation changes the price and quality. Well-known brands charge more but give better machines and help. Buyers trust brands that care about quality and the environment. Companies that focus on green packaging get more customers. Good reputation and quality help buyers pick the best machine for their money and the planet.

Tip: Buyers should look at machine type, automation, how many bags it makes, custom features, and supplier reputation before buying a paper bag making machine.

Tips for Choosing Paper Bag Making Machines

Evaluating Supplier Credentials

Buyers need to check if the supplier is trusted. They should pick suppliers with a good history in packaging. Watching machine demos helps buyers see how fast and automatic the machines are. Buyers should also look at what help they get after buying. A supplier with a good name often gives better deals.

Pick suppliers with lots of experience.

Watch demos of automatic and fast machines.

Check what help you get after buying.

Tip: Choose suppliers who show their machines and give good help. Ask at least three suppliers for prices and compare what they offer.

Assessing Machine Quality

Good machines help make better packaging and help businesses do well. Buyers want automatic machines that work well every time. They check if the machine can use different kinds of paper. Fast machines should be accurate and steady. The table below shows what to look for in a good machine:

| Criteria | Description |

| Machine Adaptability | Can use many paper types and eco-friendly paper. |

| Accuracy and Stability | Keeps colors, shapes, and glue neat for bags. |

| Scrap Rate | Makes less waste when making bags. |

| Key Functional Modules | Has strong parts for feeding paper, glue, shaping, and handles. |

| Maintainability | Easy to clean and fix for good use. |

| User-Friendliness | Simple controls and easy for workers to use. |

Note: Buyers should watch machine demos and check details before picking a machine.

Negotiating Price

Talking about price helps buyers not spend too much. Buying lots of paper rolls at once can save 10-15%. Talking with suppliers often can help get better deals. Buyers should look at prices from different suppliers to find the best one. Small budgets can use semi-automatic machines, while big companies can buy fully automatic ones.

Buying in bulk saves money and helps profits.

Talking with suppliers can get better prices.

Comparing prices helps buyers not spend too much.

Considering After-Sales Service

Good service after buying helps keep machines working well. Buyers should check if the company has skilled workers and lots of experience. They need to see how fast the company can help and where help is offered. It is important to know if spare parts are easy to get and not too costly. Good service after buying means less waiting and happier buyers. Training, easy help, and clear warranty rules help buyers use their machines well.

Make sure the supplier gives full training.

Check if help is easy to get.

Ask about the warranty and spare parts.

A supplier with good service and a strong name helps buyers make packaging that works well and lasts.

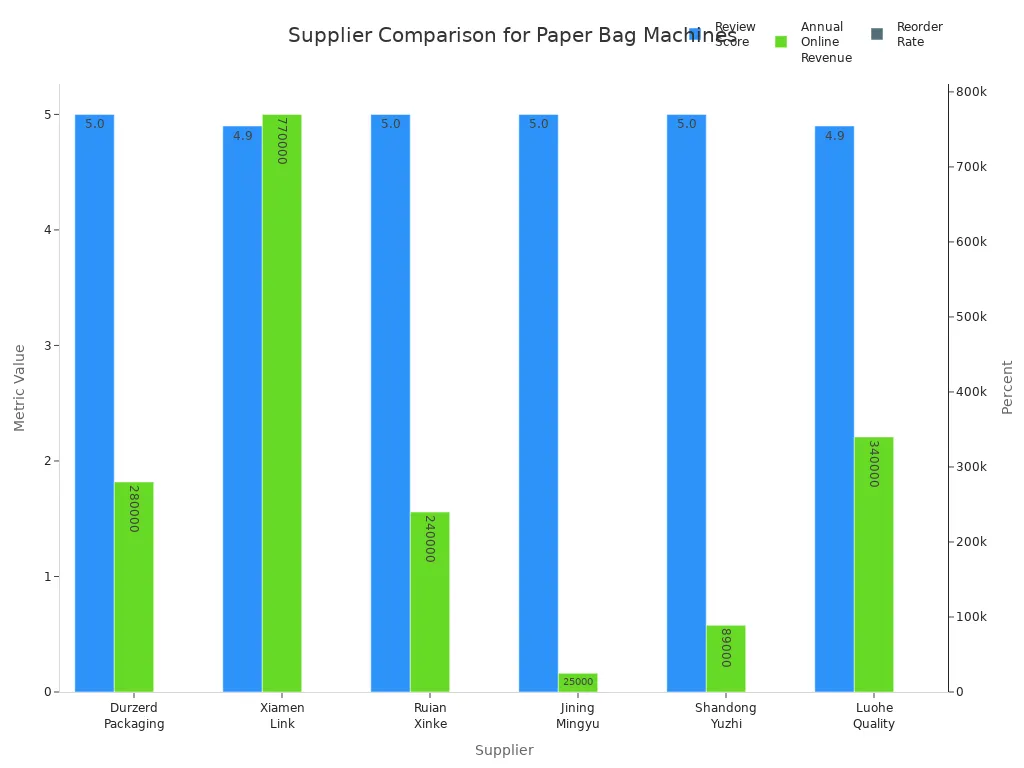

Top suppliers sell fast machines at different prices. Buyers notice if machines are eco-friendly and if the company is trusted. Fast machines are good for big jobs. Smaller machines work well for new companies. To pick the right supplier, buyers should do these things:

Look at how long the supplier has worked and how many bags they can make.

Check if the machine is eco-friendly and if it works fast.

Ask for prices and see what the warranty covers.

| Company Name | Years Active | Review Score | Reorder Rate |

| Durzerd Packaging Machinery Co., Ltd. | 4 | 5.0 | 33% |

| Xiamen Link Machinery Technology Co., Ltd. | 5 | 4.9 | 40% |

| Ruian Xinke Machinery Co., Ltd. | 15 | 5.0 | 33% |

![Bar charts comparing review scores, annual online revenue, and reorder rates for paper bag machine suppliers]()

Buyers who compare suppliers and follow these steps pick the best machines for their packaging needs.

FAQ

What factors affect the price of a paper bag making machine?

Many things can change the price. The type of machine matters a lot. How fast the machine works is important too. Machines with more automation cost more money. Suppliers who give better help and longer warranties charge higher prices. Buyers should look at all features before they choose.

How much does it cost to maintain a paper bag making machine?

Cleaning the machine often helps it work well. Checking parts keeps the machine running smoothly. Most suppliers give help and sell spare parts. The cost to keep the machine working depends on its size. How much you use the machine also changes the cost.

Which machine is best for small businesses?

Small businesses usually pick semi-automatic machines. These machines do not need much money to buy. Fewer workers are needed to run them. They are good for making fewer bags. New companies can start packaging quickly with these machines.

Do suppliers offer training for new buyers?

Many suppliers teach buyers how to use new machines. Training helps workers learn to use and fix the machine. Good training makes work safer and faster for everyone.

Can machines make different types of paper bags?

Most new machines can make many kinds of bags. Buyers should check if the machine can change bag sizes and shapes. Some machines work with eco-friendly paper for green packaging.