Small businesses that make packages need good machines to thrive. The latest die creasing machines feature smart automation and eco-friendly components. These advancements help workers increase productivity while reducing costs. Energy-efficient machines can lower bills by 20% and consume less electricity. Machines equipped with automation significantly save on labor expenses and help minimize waste. Check out the table below for more details.

| Feature | Impact on Costs and Efficiency |

| Energy-efficient machines | Lower costs by 15-20%, use 25-35% less electricity |

| Automation features | Save up to 50% on labor costs, cut material waste |

| Quality control features | Fewer defects, better quality, more savings |

Key Takeaways

Buying new die creasing machines can help small businesses save money. They use less energy, so costs go down by 15-20%. Labor costs can drop by half with these machines.

Modern machines have automation features. These features let you change jobs fast. This helps you work quicker and waste less material.

Picking eco-friendly machines is good for the planet. It also helps you save money over time.

Small businesses need to think about what they need. They should look at how much they make and what materials they use. This helps them pick the right die creasing machine.

Good suppliers like Oyang give support and training. This makes sure your machines work well and do their job right.

Latest Die Creasing Machines Overview

Key Innovations in 2024

The world of die creasing is always changing. In 2024, the newest machines have smart features for small businesses. These features help people work faster and better. Many machines now have automation tools. These tools make it easy to switch jobs. Operators can change tasks with a few taps. This saves time and keeps things moving.

Here are some new automation features in today’s machines:

| Feature | Description |

| ABG Connect | Automated workflow for job changeovers, boosting production efficiency. |

| Semi-rotary flexo head | New head design for sleeve or cylinder use, with motorized impression settings. |

| Infinity turret | Automatic turret for different label types, with automatic changeover. |

Modern machines use servo-hydraulic systems. These systems control speed and power. The machine only uses energy when needed. This means less wasted electricity and lower oil temperatures. The machines also cut more precisely. This leads to fewer mistakes and less scrap.

Tip: New die creasing machines help save money. They use less energy and make less waste. They also follow strict environmental rules. This helps companies protect the planet.

Why Small Businesses Need the Latest Technology

Small businesses have a lot of competition. They must work fast and keep costs low. They also need to make high-quality products. The latest die creasing machines help with all of this. These machines use advanced technology to make work easier.

Modern machines save energy, so businesses pay less for power.

Automation and digital controls let workers make quick changes. This helps reduce waste.

Companies can use eco-friendly materials and still get good results.

The machines help businesses meet their sustainability goals by using less energy.

Small businesses with the latest die creasing machines can do more jobs. They finish work faster and offer better quality. This keeps customers happy. By using new technology, small companies can grow and stay ahead.

Quick Comparison of Top Models

Specifications and Features

Picking the best machine can be hard. Small businesses want machines that are fast and save energy. They also need to fit in small spaces. The Oyang Die Cutting Machine is very accurate. It can switch jobs quickly and cut many materials like cardboard and PET film. This machine uses new technology for perfect cuts. It can handle tough jobs. People say it is simple to use and fix. This means the machine does not stop working often.

Other good machines, like the HL-ML-930, work well for small shops. It can cut pieces up to 930×660 mm. It makes about 25 cuts each minute. The machine weighs 3,800 kg and has a 4 kW motor. It is strong and works well every day.

Here is a table with some details:

| Model | Max Die Cutting Size (mm) | Speed (cuts/min) | Power (kW) | Weight (kg) | Dimensions (mm) |

| Oyang Die Cutting Machine | Multiple formats | Top speed | Advanced tech | Heavy-duty | User-friendly design |

| HL-ML-930 | 930×660 | 25±2 | 4 | 3,800 | 1960×1760×1720 |

Tip: Machines that change jobs fast help small businesses do more work in less time.

Price Range and Use Cases

The cost of new die creasing machines is different for each model. Some, like the MBM AeroDieCut, cost about $74,998. Others, like the Count iCrease Pro Plus, are cheaper at $7,714.25. The MBM GoCrease 4000 is an entry-level machine and starts at $2,939. Small businesses choose a machine based on their money and what they need to make.

| Machine Name | Price |

| MBM AeroDieCut Platen Die Cutter with Creaser, Perforator, & Embosser | $74,998.00 |

| Count iCrease Pro Plus Digital Creasing & Perforating Machine | $7,714.25 |

| MBM GoCrease SEMI 17.7" Semi-Automatic Programmable Creaser & Perforating Machine | $7,349.00 |

| MBM GoCrease 4000 Creasing & Perforating Machine | $2,939.00 |

Oyang’s machine is good for fast jobs and many types of packaging. It also works for greeting cards and cartons. The HL-ML-930 is best for shops with steady work and medium-sized jobs. MBM machines are great for people who want digital controls and easy setup for small batches.

Small businesses should pick machines that fit their work and materials. The newest die creasing machines help them save money, work faster, and make better products.

Essential Features for Small Businesses

Size and Space Requirements

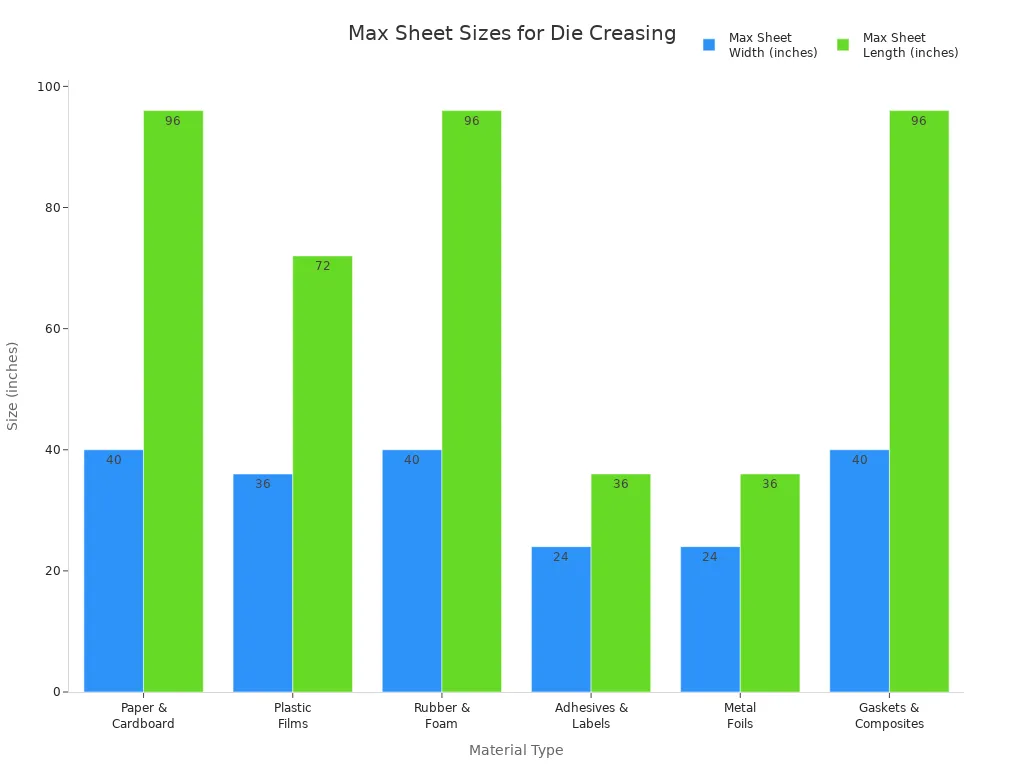

Small businesses usually have small work areas. They need machines that do not take up too much room. Die creasing machines come in different sizes. Some can handle big sheets. Others work with smaller rolls. The table below shows the biggest sizes for each material.

| Material | Max Sheet Size (Flatbed) | Max Roll Width (Rotary) | Thickness Limit (Flatbed) | Thickness Limit (Rotary) |

| Paper & Cardboard | 40″ x 96″ | 16″ | Up to 0.5″ | Up to 0.015″ |

| Plastic Films | 36″ x 72″ | 16″ | Up to 0.25″ | Up to 0.015″ |

| Rubber & Foam | 40″ x 96″ | 16″ | Up to 0.5″ | Up to 0.015″ |

| Adhesives & Labels | 24″ x 36″ | 16″ | Up to 0.125″ | Up to 0.015″ |

| Metal Foils | 24″ x 36″ | 16″ | Up to 0.1″ | Up to 0.015″ |

| Gaskets & Composites | 40″ x 96″ | N/A | Up to 0.5″ | N/A |

![Bar chart comparing maximum sheet width and length for various materials in flatbed die creasing machines]()

Speed and Automation

Speed is important for small shops. New die creasing machines can work on thousands of sheets every hour. For example, the Highcon Beam 3 can do up to 5,000 sheets in one hour. Fast machines help finish jobs quickly. This means they can take more orders. Automation helps a lot too. Machines with auto ladle, auto sprayer, and auto extractor do more work by themselves. These features make the job easier and safer.

| Automation Feature | Description | Benefits |

| Auto Ladle | Transfers molten metal into the die | Consistent pouring, fewer spills, steady temperature |

| Auto Sprayer | Applies release agent on die surfaces | Prevents sticking, speeds up cycles, boosts efficiency |

| Auto Extractor | Removes cast parts after cooling | Less manual handling, more productivity, lower damage risk |

Tip: Automation lets workers do other jobs. It helps the shop run smoother.

Ease of Use and Maintenance

Owners want machines that are simple to use. Easy controls help workers learn fast. No special training is needed to use the machine. Cleaning, checking, and lining up the machine keeps it working well. The table below lists what needs to be done for upkeep.

| Maintenance Requirement | Description |

| Cleaning | Remove fibers and debris for smooth operation |

| Inspection | Check moving parts for wear and tear |

| Alignment and Recalibration | Test die alignment for accurate cuts |

Cleaning: Take out dirt and dust often.

Inspection: Check for broken or worn parts.

Alignment and Calibration: Make sure dies are lined up right.

The machine has easy controls so anyone can use it. You do not need special training to run the machine.

Eco-Friendly and Sustainable Options

Eco-friendly machines help save money and protect nature. Some models use AI to cut waste by 25%. Others work with recycled materials and last longer. The table below shows how these features help.

| Machine Model | Eco-Friendly Feature | Description |

| Pro Model | AI-optimized waste reduction | Cuts scrap by 25%, boosts sustainability |

| Base Model | Handles recycled materials | Processes recycled cardboard without jams |

| Pro Model | Durability with eco-materials | Runs smoothly with eco-friendly materials, needs less maintenance |

| Aspect | Description |

| Enhanced Precision | Modern machines provide exceptional cutting accuracy, ensuring consistent product quality. |

| Increased Production Efficiency | High-speed operation and quick job changeovers minimize downtime, boosting overall throughput. |

| Material Waste Reduction | Automated waste matrix stripping and precise registration systems significantly cut material waste. |

| Automation | Reduces labor costs and increases output per shift, improving profitability. |

Small businesses that pick green machines can save money and help the planet. The newest die creasing machines have smart features for better work and a cleaner world.

Oyang Die Cutting Machine Review

Performance and Precision

The Oyang Die Cutting Machine is known for working really well and making sharp cuts. It uses new technology to make every cut neat and right. People who use it see that it works quickly, even on hard jobs. The smart controls help keep each job going smoothly. Oyang’s machine makes fewer mistakes, so there is less waste. This helps businesses save money and get better results. The machine is strong and can run for many hours without stopping. Many people say they trust it for big jobs and when time is short.

Tip: Oyang’s machine can make things over 30% faster than older machines.

Versatility and Material Compatibility

Oyang’s machine can work with many different materials. It does a good job with paper, cardboard, plastics, rubbers, foams, electrical films, and fabrics. This is helpful for shops that need to do many kinds of work. The table below shows how Oyang matches up with other top machines:

| Material Type | Oyang Die Cutting Machine | Other Leading Machines |

| Plastics | Yes | Yes |

| Rubbers | Yes | Yes |

| Foams | Yes | Yes |

| Electrical films | Yes | Yes |

| Cardboard | Yes | Yes |

| Fabrics | Yes | Yes |

| Paper | Yes | Yes |

Oyang’s machine can handle all the main materials that small businesses use. Shops can do more jobs without buying more machines.

User Experience and Support

Oyang makes its machines easy for anyone to use. The controls are simple, so workers learn fast. Quick change features help teams switch jobs quickly, so work does not slow down. It is also easy to keep the machine clean and check the parts. Oyang gives good customer support. Their team helps with setup, training, and answers questions. Many customers say they feel safe knowing help is always there.

Note: Oyang’s support and fast technical help make it better than many other brands.

The Oyang Die Cutting Machine gives small businesses the power and choices they need. It has the best features of new die creasing machines and adds easy use and strong support.

Cost and ROI Insights

Investment and Budgeting Tips

Small businesses often wonder how much to spend on a die creasing machine. The price can range from a few thousand dollars to over $200,000. Owners should look at their budget and think about what features matter most. Machines with automation and energy-saving options may cost more upfront, but they help save money over time.

Here are some tips for smart investing:

Make a list of must-have features. Focus on what helps the business grow.

Compare prices and check what is included. Some machines come with training or support.

Ask about maintenance costs. Reliable machines need less repair and last longer.

Plan for future growth. A machine that handles more jobs can help the business expand.

Tip: Owners who choose machines with quick changeover and automation often see faster payback. These features help reduce labor costs and boost output.

A simple table can help compare costs:

| Machine Type | Upfront Cost | Yearly Savings | Maintenance Cost | Payback Time |

| Entry-Level Manual | $3,000 | $2,000 | Low | 1.5 years |

| Mid-Range Automatic | $25,000 | $10,000 | Medium | 2.5 years |

| Advanced Automated | $200,000 | $150,000 | Low | 1.3 years |

Calculating Return on Investment

Business owners want to know if a new machine will pay off. They can use simple formulas to figure out the return.

To find the internal rate of return (IRR), use:

IRR = (Savings – Machine Cost) / Machine Cost x 100

For example, if a machine costs $40,000 and saves $25,000 each year, the IRR is 15% over 10 years.

Automation can cut labor costs by up to 50%. Owners should compare labor costs before and after buying the machine.

The formula for ROI is:

(Net Gain or Loss from Equipment / Total Cost of Equipment) x 100

If a machine brings $150,000 in net benefit each year and costs $200,000, the ROI is 75%.

Note: Machines that save time and reduce waste often give the highest returns. Owners who track savings and costs can see how quickly their investment pays off.

Calculating ROI helps small businesses make smart choices. They can see how much money they save and how fast the machine pays for itself.

Choosing the Right Die Creasing Machine

Assessing Business Needs

Small businesses should think about what they need before buying a die creasing machine. They need to check what jobs they do most. They should look at the materials they use every day. It is important to know how much space is in the shop. The table below lists key things to think about:

| Factor | Description |

| PLC Control System | User-friendly interface that allows job presets, speed, pressure, and feeding cycle adjustments. |

| Feeder Mechanism | Supports smooth operation for different materials with registration sensors for alignment. |

| Changeover Time | Fast die changes and minimal calibration for operations with multiple product lines. |

| Die Compatibility | Must accommodate various tools like steel rule dies, rotary dies, or digital knives. |

| Cutting Pressure | Adequate force and precision for thick, layered, or specialty materials to maintain output standards. |

Advanced technology and automation can cost more money. But these features make work easier and more accurate. Good materials help the machine last longer and cost less to fix. A trusted brand may be more expensive, but it breaks down less.

Matching Features to Production Volume

How much a shop makes each day is important. Owners should know how many things they need to make. Machines that work faster help busy shops finish more orders. Adjustable creasing depth is needed for different paper types. Micro adjustment settings help make every item look neat and waste less.

Check how much you need to make each day to pick the right machine.

Think about the materials you use, since adjustable creasing depth helps with different paper.

Find machines with micro adjustment settings for better quality and less waste.

Supplier Evaluation and Support

Picking a good supplier is very important. Oyang is a good choice because they answer questions fast. They make it easy to get spare parts when needed. Their team helps set up the machine and keeps it working well. Ongoing help means fewer problems and less time when the machine is not working.

Fast answers from suppliers help stop work delays.

Easy spare parts mean repairs are quick.

Ongoing help keeps machines working their best.

Tip: Small businesses that choose good suppliers like Oyang get more from their die creasing machines and have better results for a long time.

Choosing the latest die creasing machines helps small businesses save money, work faster, and protect the environment. Oyang’s Die Cutting Machine stands out with its smart features and strong support. Every business has different needs. Readers should think about what matters most for their shop. For expert advice or a demo, they can visit Oyang’s website or contact the team.

Ready to upgrade? Reach out to Oyang for the right solution!

FAQ

What materials can a die creasing machine handle?

Die creasing machines can work with paper and cardboard. They also handle corrugated board, cartons, and some plastics. Many small businesses use them for packaging and greeting cards. They are also used for making labels. Oyang’s machine works with many materials. This makes it a good and flexible choice.

How often should someone maintain a die creasing machine?

Cleaning and checking the machine often keeps it working well. Most shops look at their machines every week. Simple jobs like dusting and checking parts help stop problems. Oyang’s machines are simple to take care of.

How long does delivery take for a new machine?

It usually takes 1 to 2 months to get a new machine. This is after you order and pay the deposit. Oyang gives updates during this time. Buyers always know what is happening with their machine.

Does Oyang offer training or support after purchase?

Yes! Oyang helps set up the machine and gives training. They also give support after you buy it. Their team answers questions fast and helps with any problems. Many customers say this support really helps them.