Everyone who works on a bag-making machine knows that the two words most feared to appear on the production line are "running off-track".

Once the paper deviates, it leads to a chain reaction: the bag body becomes skewed, the patterns misaligned, and the bottom bonding misplaced. At the least, it results in a pile of defective products; at worst, it can cause paper jams, machine downtime, and even damage to the cutting blade.

When many operators encounter paper deviation, their first reaction is to frantically press the buttons on the EPC (Error Correction Controller) or increase the correction force. However, often after a long time of tinkering, as soon as the machine accelerates, the paper deviates again.

As a factory technician who has been involved in this industry for over a decade, I want to tell you: not all belt misalignments are the fault of the belt alignment system. Many times, it's because you have overlooked those seemingly unimportant "mechanical details" during machine operation.

Today, I will reveal 3 details of error correction that are most easily overlooked by 90% of operators due to their habitual thinking.

Detail 1: This is not a "correction" issue, but a "tension" issue

(Ignore index: ★★★★★)

Many operators, upon discovering paper deviation, fixate solely on the correction probe, neglecting to observe the **"Dancing Roller"** located behind.

Technical truth:

During high-speed movement, the paper must maintain a constant tension. If the magnetic powder brake (or servo motor) at the unwind position is not properly set, or if the paper roll itself is "loose on one side and tight on the other", it can cause lateral slippage of the paper during travel.

When the tension is too low, the paper becomes floppy and the alignment system cannot grasp it at all; when the tension is too high, the paper is pulled too tightly, and even a slight adjustment in the alignment action can cause the edges of the paper to wrinkle or tear.

✅ Tips from an experienced craftsman:

Don't just focus on adjusting the deviation, first check the tension system. Observe whether the floating roller (dancing roller) is slightly floating up and down in the horizontal position?

If the floating roller collides violently with the upper and lower limits, it indicates that the tension is extremely unstable. At this point, no matter how you adjust the correction, it will be useless.

Pithy formula: First stabilize the tension, then adjust the base note for deviation correction.

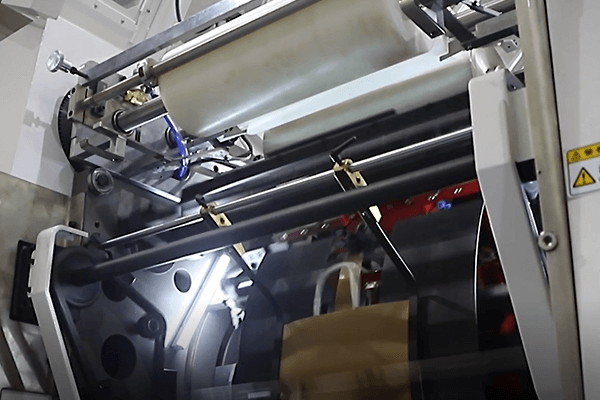

Detail 2: The "invisible killer" on the paper roller - glue residue and ink

(Ignore the rating: ★★★★☆)

![Glue Glue]()

Why does the machine, which has been running for a long time, suddenly start to deviate from the stable path it was on?

It is highly likely that the guide roller is dirty.

Technical truth:

When using a bag-making machine, especially for in-line printing or gluing processes, the surface of the aluminum roller or rubber roller is prone to accumulating a very thin layer of glue residue, paper dust, or dried ink.

These contaminants can lead to uneven friction coefficients. One side of the roller experiences high friction (grasping the paper), while the other side has low friction (the paper slips). Naturally, the paper will deviate towards the side with higher friction, or drift towards the side where it slips (depending on the driving method). At this point, relying solely on the photoelectric sensor for correction is only addressing the symptoms and not the root cause.

✅ Tips from an experienced craftsman:

Develop the habit of conducting a shutdown inspection. Use your hand to feel the surface of the paper roller at key positions to check if there are any foreign objects that feel rough or sticky?

Regularly wipe the paper rollers with alcohol or a dedicated cleaning agent. You will find that even if you just clean a few rollers, the problem of deviation often magically disappears.

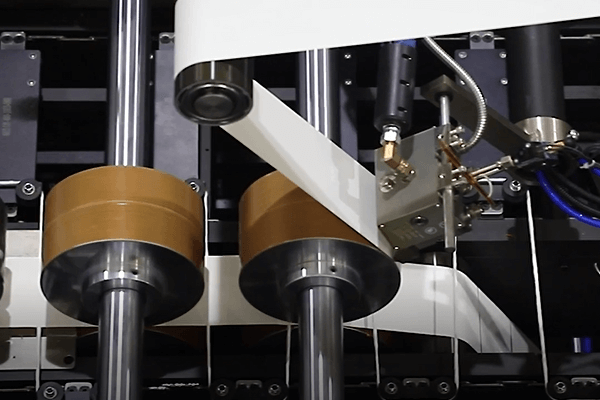

Detail 3: Asymmetrical "gap" of the molded board

(Ignore index: ★★★☆☆)

![Molding Template Molding Template]()

This is the most subtle issue in the tube forming stage. When you find that the center seam of the bag is not aligned no matter how you adjust it, or it always tilts to one side, it is most likely because the former is not installed flat.

Technical truth:

When the paper is folded by the forming plate, it needs to be pressed together by the pressure rollers. If the pressure applied by the left and right pressure rollers is not consistent, or if the gap between the forming plate and the base is larger on the left and smaller on the right, the resistance experienced by the paper will be uneven.

Paper is also "bullying the weak and fearing the strong", it always tends to move towards the side with less resistance (larger gap). This mechanical and physical deviation is difficult to correct using an electronic correction system.

✅ Tips from an experienced craftsman:

Take a feeler gauge and check whether the gaps on both sides of the forming plate are consistent when the machine is stopped. Do not rely solely on visual inspection, as a 0.5mm error can be magnified into a significant deviation under high-speed operation. Ensure that the "tightness" on both sides is consistent.

Conclusion: A good machine also needs to understand fine-tuning

We often tell our customers that purchasing a machine is the first step, and understanding it is the second.

A good bag-making machine should be equipped with a high-sensitivity servo correction system (such as the BST or Pausource correction system used in our new model), which can help operators solve 80% of the common running deviations. But for the remaining 20%, it relies on the operator's understanding of tension, friction, and pressure.

If you encounter any difficult problems in production that you cannot solve, or if you want to know how to reduce the waste caused by "human negligence" by upgrading equipment, please feel free to contact me through the back-end system.

Sometimes, solving a big problem only requires a small adjustment.