Market Backgroud

Flat rope paper bags and small batch orders stil rely on pure handmade production;

Most of the paper bag processes on the market are side edge sealing + bottombonding, and the bottom is the main stress-bearing part of the paper bag, which easilyleads to bottom degumming;

When the bag is folded flat, there is a waistline on the front and a waistline with largecharacters on the side. The bottom is multi-loyered and the lines are complicatedwhich destroys the integrity of the paper bag and the printed pattern;

There is no bonding on the inside of the bag opening, and the inside is elastic, whichaffects its use.

Highlights Of New Technology

Solve That Existing Pap Bag Process Problems

We provide a "fully automated U-shaped wrapping and center-sealing on bothsides" bag-making process, in which the flat rope threading and bag-making arecompleted automatically.

Solve The Problem OfBottom Degumming

The bottom is used as the center to form a U shape, and the two sides are sealed atthe center fold lines, and the bottom is a whole flat bottom.

Maintain Load-Bearing Capacit

20KG 以上Automatic rope threading and hot melt adhesive automatic spraying process, theload-bearing capacity reaches more than 20KG.

Solve The Problem OfBag Surface Aesthetics

The front is neat and elegant, and there is only a fold line on the side, which will not damage the printed pattern.The folding method is the bottom M bottom inner foldThe inner fold of the bag mouth is bonded into a whole, without rebound, and easy touse.

Comparison Of Finished Paper Bag Of New And Old Technology

![]()

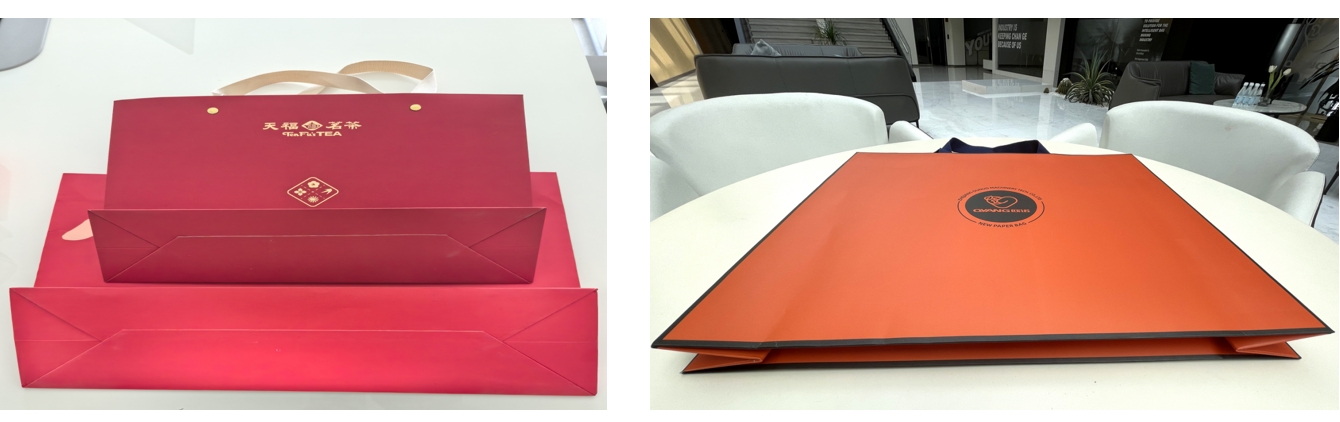

Old Technology

![]()

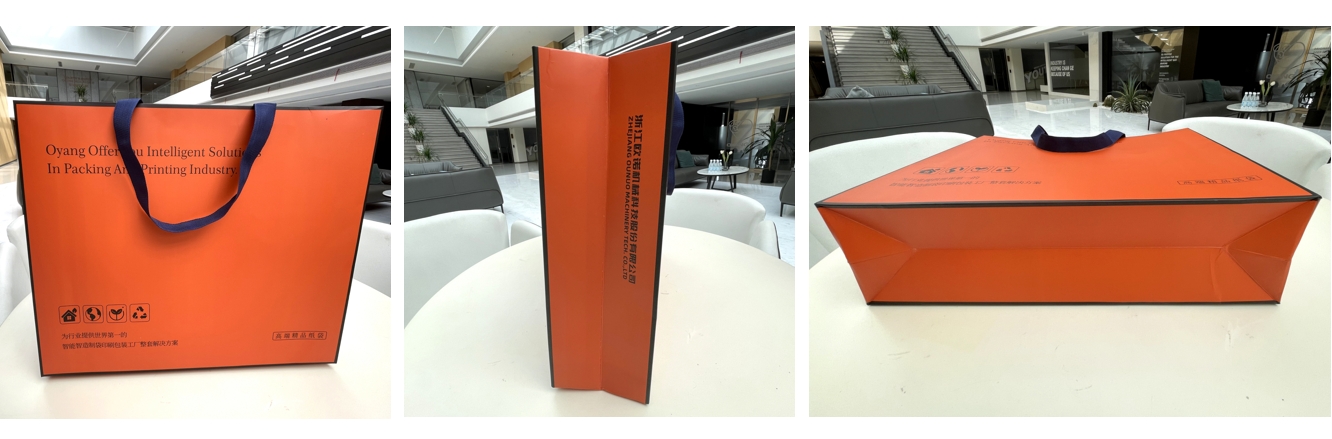

New Technology

![]()

Folded State Of Old & New Technology