Choosing the right die creasing machine helps your business grow. You should match machine features to how much you make, what materials you use, and your daily work. Many small businesses want machines that work with many materials and change quickly. Today, eco-friendly and smart machines help lower costs and save energy.

Oyang’s solutions help small businesses work better and make good products.

The automatic die-cutting machine market will be worth USD 3.1 billion by 2034. It will keep growing each year.

North America will see strong growth. The market will go from USD 1.20 billion in 2024 to USD 1.85 billion by 2033.

| Feature | Impact on Costs and Efficiency |

| Energy-efficient machines | Lower costs by 15-20%. Use 25-35% less electricity. |

| Automation features | Save up to 50% on labor costs. Cut material waste. |

| Quality control features | Fewer defects. Better quality. More savings. |

Key Takeaways

Pick a die creasing machine that fits your business size. Make sure it meets your production needs. This helps you work faster and saves money.

Find machines that use less energy. They help you spend less on electricity. These machines also make less waste. You can save a lot on running costs.

Think about machines with automation features. They help you finish jobs faster. You will need fewer workers. Automated machines make fewer mistakes.

Check if the machine works with your materials. It should handle different types of packaging. This lets you change materials when needed.

Take care of your machine often. Follow a schedule for maintenance. This keeps your machine working well. You can avoid big repairs and stop losing time.

Why die creasing machines matter

Boosting production efficiency

Die creasing machines make packaging faster. You can make lots of packages without stopping much. Automation helps you set up jobs quickly. Digital controls keep things running smoothly. Smart sensors change settings as you work, so you waste less. AI-powered systems help you finish orders faster. You save money because machines do more work. This means you need fewer workers and can finish big jobs quickly.

Tip: Energy-efficient machines use less electricity. They help you save money and reach your production goals.

Here is how die creasing machines help you work better:

| Advantage | Description |

| Continuous, high-speed operation | You make more packages in less time. |

| Superior precision and repeatability | You get the same good results every time. |

| Reduced material waste | You use less material and save money. |

| Efficient processing of complex patterns | You can make detailed designs for many packaging needs. |

Enhancing product quality

You want your packages to look neat and protect your products. Die creasing machines help you make clean lines and strong folds. Many industries need better packaging, like food and medicine. These machines help you give customers high-quality boxes. Automation lets you change designs and make boxes look nice. You get fewer mistakes, so customers get better products.

More businesses want die creasing machines for better packaging.

Online stores use these machines to make cool boxes that protect items.

Energy-efficient machines help you keep quality high and save money.

Supporting sustainable packaging

You can help the planet by picking die creasing machines that use less energy. These machines waste less material. You save money and help nature. Easy controls make training simple, so your team learns fast. Strong machines break less, so you spend less fixing them. Using energy-efficient machines shows customers you care about the environment.

Automated machines lower labor costs and help you work faster.

Good controls mean you use only what you need, so you waste less.

Tough machines last longer, so you buy new ones less often.

Die creasing machines help you work faster, make better products, and protect the environment.

How to choose a die creasing machine

Assessing your business needs

First, think about how big your business is. Decide what you want to do with your machine. Small businesses and big factories have different needs. Count how many packages you make each day. Know what products you want to create. Some machines are good for small jobs. Others are better for large jobs.

Here is a table to help you pick the right die creasing machine:

| Factor | Description |

| Intended Use | Pick machines for hobbies, small businesses, or factories. |

| Budget | Plan for buying and paying for supplies later. |

| Material Compatibility | Make sure the machine works with your materials. |

| Features and Functionality | Check for software, size, and extras like embossing. |

| Support and Community | Good support helps you fix problems and learn new things. |

Tip: Write down what you need before you shop. This makes it easier to choose the best machine.

Material compatibility and flexibility

Check if the die creasing machine works with your materials. Small businesses use paper, cardboard, or corrugated boards. Some machines also work with plastic or coated paper. You need a machine that matches your material thickness and type.

Here are some machine types and what they can do:

| Machine Type | Supported Materials | Maximum Thickness |

| Die-cutting and Creasing Machine | Paper, Cardboard, Corrugated Boards | N/A |

| Vertical Creasing Machine | Plastic, Paper | 0.2-5.0mm |

| Rotary Paper Die Cutting Machine | Normal Paper, Coated Paper, Cardboard | N/A |

Die creasing machines work with paper, cardboard, and corrugated boards.

Vertical creasing machines handle sheets from 0.2 to 5.0mm thick.

Rotary machines process normal paper, coated paper, and cardboard.

If you change materials often, get a machine with quick changeover features. Oyang’s machines are flexible for many packaging types. You can use them for cartons, paper boxes, and PET film. This helps small businesses keep up with new needs.

Production volume and scalability

Pick a machine that matches how much you make. Small businesses may start with short runs. You might want to grow later. Some machines are best for small batches. Others can make thousands of packages each day.

Here is a table to help you find the right machine for your work:

| Machine Type | Max Sheet Size | Typical Material Range | Max Sheet Length | Best For |

| Desktop / Benchtop | 330mm × 480mm | 80–300gsm paper, cardstock | 480mm | Small businesses, offices, short runs |

| Mid-Format Platen | 610mm × 900mm | 80–400gsm, light board | 610mm | Brochures, catalogs, medium-volume work |

| Large-Format Static | 920mm × 1200mm | 100–500gsm, corrugated | 1000mm | Commercial printing, packaging prototypes |

| Rotary / Inline | Up to 1200mm × 1500mm | 80–600gsm, plastic, laminates | 1200mm+ | High-volume production, integrated lines |

If you want to grow, pick a machine that can grow with you. Automatic machines help you finish more work faster. Oyang’s smart machines let you do more when you get more orders. You can add new services and take bigger jobs. This saves time and helps you make fewer mistakes.

Note: Starter machines are good for small businesses. Advanced machines help you do more as your business grows.

Eco-friendly and smart machines, like Oyang’s, help you follow packaging rules. These machines use recyclable materials and work quickly. You protect the environment and help your business. Oyang’s technology lets you make packages fast and look good. You show customers you care about the planet.

When you pick a die creasing machine, think about your business size, materials, and how much you make. Look for important features like flexibility, speed, and eco-friendly choices. Oyang’s machines help small businesses work better and grow faster.

Key features of Oyang Die Cutting Machine

Precision and speed

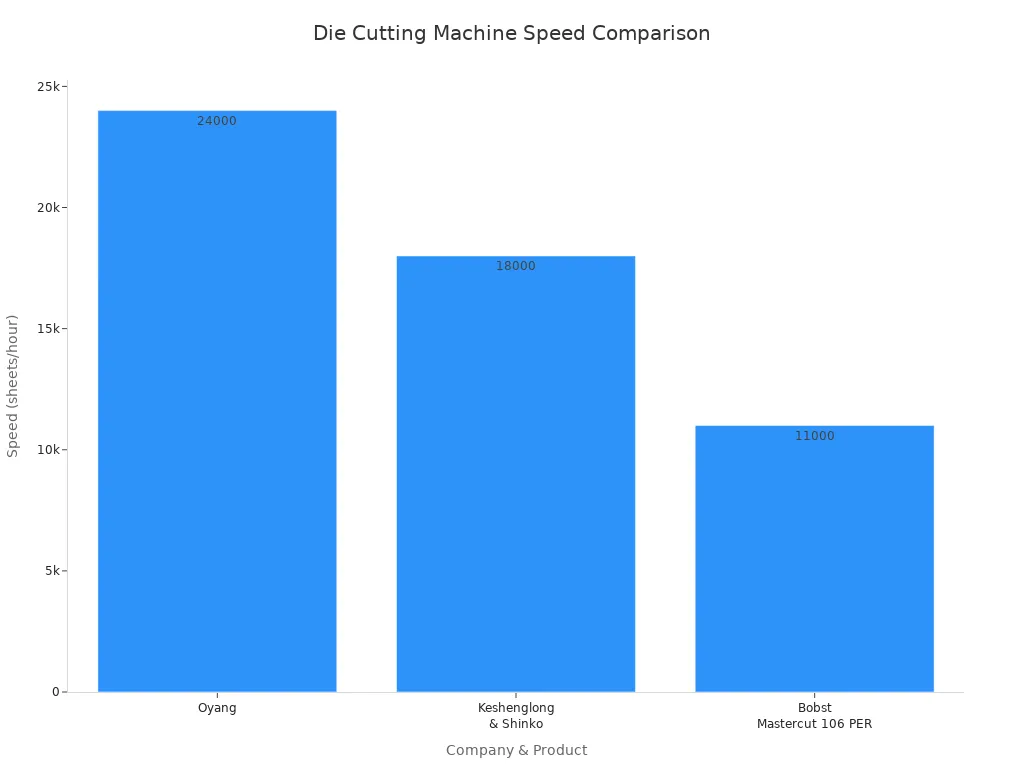

You want your packages to look neat and nice. Oyang Die Cutting Machines help you cut with great accuracy. These machines work fast, so you finish jobs quickly. The table below shows how Oyang compares to other brands:

| Company & Product | Max Sheet Size (mm) | Speed (sheets/hour) | Key Advantage | Application Area | Origin | Investment Level |

| Oyang | Customizable | Up to 24,000 | Eco-friendly, smart automation | Packaging, printing | China | Medium-High |

| Keshenglong & Shinko | 1,800 x 1,200 | 18,000 | Integrated print & die-cutting | Corrugated cartons | China/Japan | High |

| Bobst Mastercut 106 PER | 1,060 x 760 | 11,000 | Precision automation, quick change | Folding cartons | Switzerland | Very High |

![Bar chart comparing die cutting machine speeds by company]()

Oyang machines use automation to keep work moving. You get the same good results every time. You also save time on each project.

Versatility for various materials

You might need to use paper, cardboard, or PET film. Oyang Die Cutting Machines work with many materials. This helps you take new jobs and meet customer needs. You can switch materials fast without slowing down. Automation lets you set up jobs quickly, so you spend less time changing settings.

Tip: If you want your business to grow, pick a machine that works with many materials. Oyang lets you offer more services.

User-friendly design and quick changeover

You do not want controls that are hard to use. Oyang machines have easy panels. You can teach your team fast and start working soon. Quick changeover helps you switch jobs in minutes. You spend less time setting up and more time making products. Automation also helps you avoid mistakes and keeps work smooth.

Easy controls mean you train faster.

Quick changeover helps you finish more jobs.

You get good results with every package.

Advanced technology for flawless cuts

Oyang Die Cutting Machines use new technology for perfect cuts. You get high accuracy, strong stability, and smart controls. The table below shows important features:

| Feature | Description |

| High Precision | Advanced die-cutting technology for accurate cuts. |

| High Efficiency | Fast speed, good for making many packages. |

| Strong Stability | Tough build for long hours of work. |

| Intelligent Operation | Simple control panel for easy use. |

| Versatility | Can cut many materials like cardboard. |

Quality control helps you avoid mistakes and keeps products looking good. You can trust Oyang to give you quality every time. New technology helps you meet high standards and make customers happy.

Comparing die creasing machines and brands

Leading manufacturers overview

There are many brands that make die creasing machines. Some companies are very popular and have lots of choices. Here are some top brands you should know:

Friends Engineering Company

SBL

ASAHI MACHINERY LIMITED

Tangshan Kingvida Printing Machinery Co.

Dongguang County Huayu Carton Machinery Co.

Ruian Koten Machinery Co.

RUIAN AOER MACHINERY CO.

Zhejiang Wity Machinery Group Co.

Shandong Lukes Machinery CO.

Wenzhou Guangya Machinery Co.

These brands have machines for different jobs. You can pick one based on your business size and what materials you use.

Pros and cons for business types

Die creasing machines have many good points, but there are some limits. The table below helps you see the differences:

| Advantages | Disadvantages |

| Can cut big pieces of material | Slower than rotary die-cutting machines, so less work gets done |

| Can cut thin and thick materials | Not as exact as rotary die-cutting machines |

| Cuts close shapes to save material | Cannot do printing, perforation, or lamination |

| Costs less than rotary die-cutting machines | Takes more time to set up |

If you own a small business, you may like the lower price and how flexible these machines are. You can use die creasing machines for lots of different jobs. Medium and large businesses might want faster machines for bigger orders. You should pick a machine that fits your work and future plans.

Tip: Small businesses often pick machines that save money and work with many materials.

Oyang’s value proposition

Oyang is special in the die creasing machine market. You get new technology and eco-friendly choices. Oyang showed its best machines at CHINAPRINT2025, where people from all over the world saw five top machines. You can use Oyang machines for paper bags, digital printing, and other jobs. The company works with customers everywhere and keeps making its machines better.

If you want smart automation and high accuracy, Oyang gives you results you can trust. Small businesses like easy controls and quick changeover. You can grow your business and handle new jobs. Oyang is known around the world, so you get help wherever you are.

Note: Oyang helps small and big businesses do better in packaging and printing.

Maximizing efficiency with die creasing machines

Setup and training tips

You can get better results with good setup and training. Small businesses do well when they follow these steps:

Always use the manufacturer's setup instructions for die creasing machines. This keeps everyone safe and helps the machine work right.

Train your operators before they use the machine. This stops mistakes and keeps packaging smooth.

Clean the machine every day. Take away dust and dirt so you do not have problems.

Check the blades every week. Sharp blades make nice cuts and help the machine last longer.

Plan your jobs before you begin. Good planning means fewer errors and saves time.

Use quality control checks while you work. This helps you find problems early and keeps products looking good.

Tip: Small businesses that train their teams have fewer breakdowns and get better results from die creasing machines.

Maintenance best practices

Regular care keeps die creasing machines working well. Use this table to help you remember what to do:

| Maintenance Frequency | Task Description |

| Daily | Look at the blades for dullness or wear. Clean off dust and scraps. |

| Weekly | Check vacuum bed suction. Clean air channels. Update and set CNC software. |

| Monthly | Look at blade holder and cutting parts for alignment and tightness. |

| Quarterly | Check how the whole machine works. Fix or change parts if needed. |

Small businesses that do these things avoid expensive repairs and keep making products.

Workflow integration

You can make packaging faster by using die creasing machines in your work. These machines cut and crease by themselves, so you do not need as much manual work. You get the same results every time, even for big orders. Die creasing machines let you switch jobs quickly, which helps small businesses with different needs. Many machines connect to digital job systems, so you can plan and track work easily. This setup means less waiting and helps you finish orders on time.

Note: Small businesses that use die creasing machines in their work finish jobs faster and keep customers happy.

Buyer’s checklist for die creasing machines

Essential decision points

When you pick a die creasing machine, you need to think about a few important things. Small businesses start by checking how much they want to make each week or month. You should get a machine that matches your work amount. This way, you do not waste money or slow down your jobs. Next, look at how many sheets the machine can handle every hour. If your shop is busy, you need a machine that works fast and keeps up.

Material compatibility is important for small businesses. Some machines work best with cardstock. Others can handle synthetic materials. You should see if the machine can change creasing depth. This helps you work with different thicknesses and get neat lines. Automation level is another thing to think about. You can choose manual, semi-automatic, or fully automatic machines. Automation helps you save time and make fewer mistakes.

Here is a checklist to help you choose:

Check how much you want to make.

Look at how many sheets the machine can handle.

Make sure it works with your materials.

See if you can change creasing depth.

Pick the right automation level.

Tip: Small businesses that pick machines with the right features get better results and save money.

Final considerations

Before you buy, look at things like the biggest sheet size, die thickness, and tonnage. Make sure the machine is safe and follows rules for your industry. Check how fast the machine works and how long setup takes. Think about the price, but also about how much it costs to keep the machine running. You want a machine that helps you save money over time.

Quality assurance is important. Check if the company is trusted and if the machine works well every time. If you use other machines, see if this one can work with them. Good after-sales support helps you fix problems fast. Look for a good warranty and easy ways to get spare parts.

Check technical specs and safety rules.

Think about how well it works and costs.

Look into quality and how it fits with other machines.

Make sure you get good support after buying.

️ A smart checklist helps small businesses choose well and grow strong.

You should pick a die creasing machine that fits your business plans. Find machines with fast cutting, good accuracy, automation, and flexibility. These things help you make more products and keep them looking nice. Smart and eco-friendly machines like Oyang work better than old ones. Use the checklist to help you choose. Ask experts or companies for advice that matches your needs. Check out Oyang’s machines to make your packaging and printing better.

| Feature/Advantage | Description |

| High Cutting Speed | Makes products faster for busy shops |

| Precision Cutting | Gives better quality and less waste |

| Automation | Makes work easier and saves on labor |

| Versatility | Works with many materials and sizes |

FAQ

What materials can you use with a die creasing machine?

You can use paper, cardboard, and corrugated board. Cartons also work with these machines. Some machines can use PET film and coated paper too. Always look at your machine’s manual to see what it supports.

How often should you maintain your die creasing machine?

Clean the machine every day to keep it nice. Check the blades once a week for sharpness. Each month, look at the moving parts for problems. Every three months, check the whole machine. Taking care of your machine helps it work well.

Can you use Oyang Die Cutting Machines for small businesses?

Yes, Oyang machines are good for small businesses. They have easy controls and quick job changes. You can use many materials with them. Start with small jobs and grow your work over time.

How long does delivery take for Oyang machines?

Oyang usually sends machines in one or two months after you pay. You can ask their team for updates or special help if you need it.