Quid est rotogravure printing?

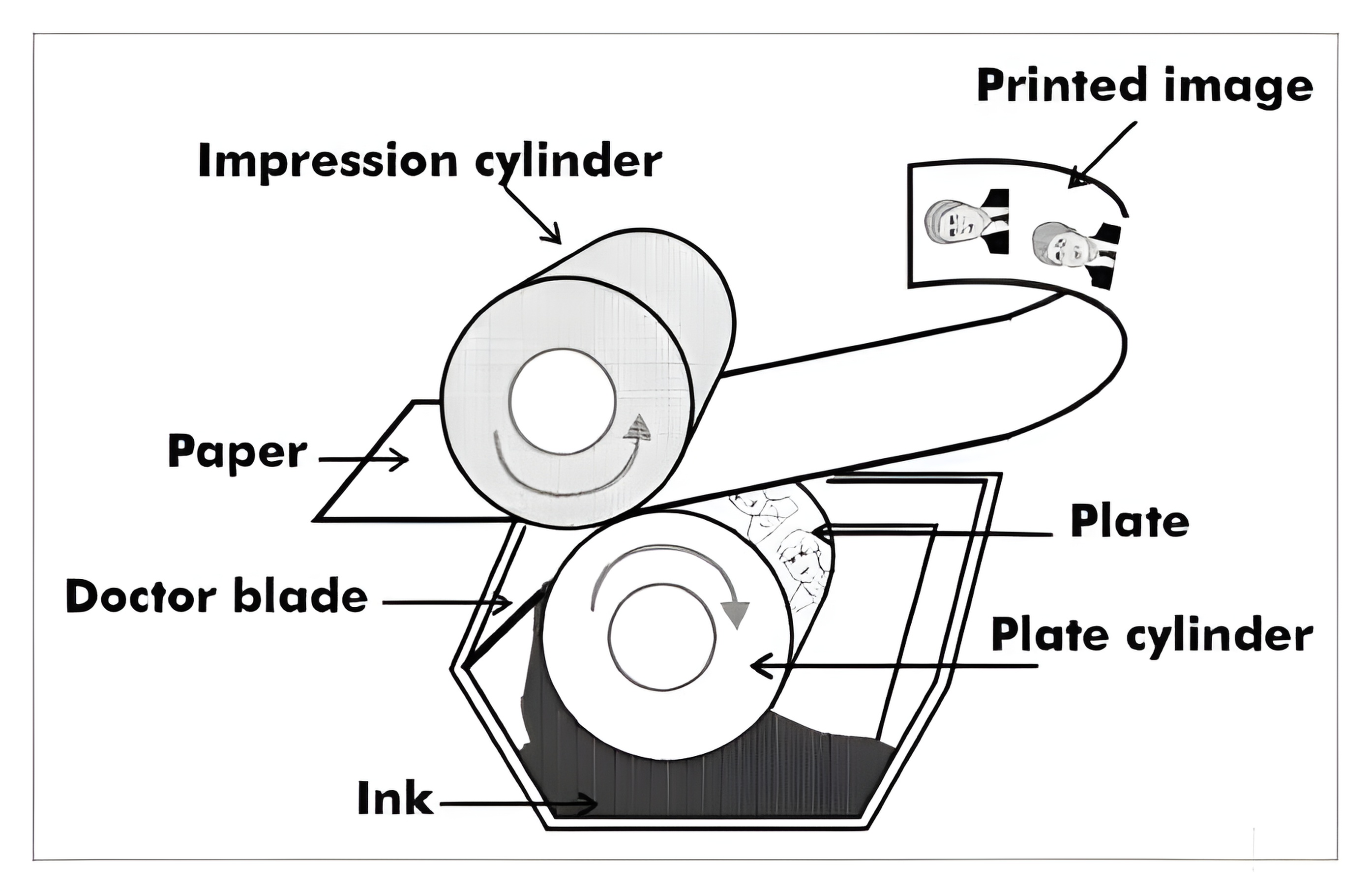

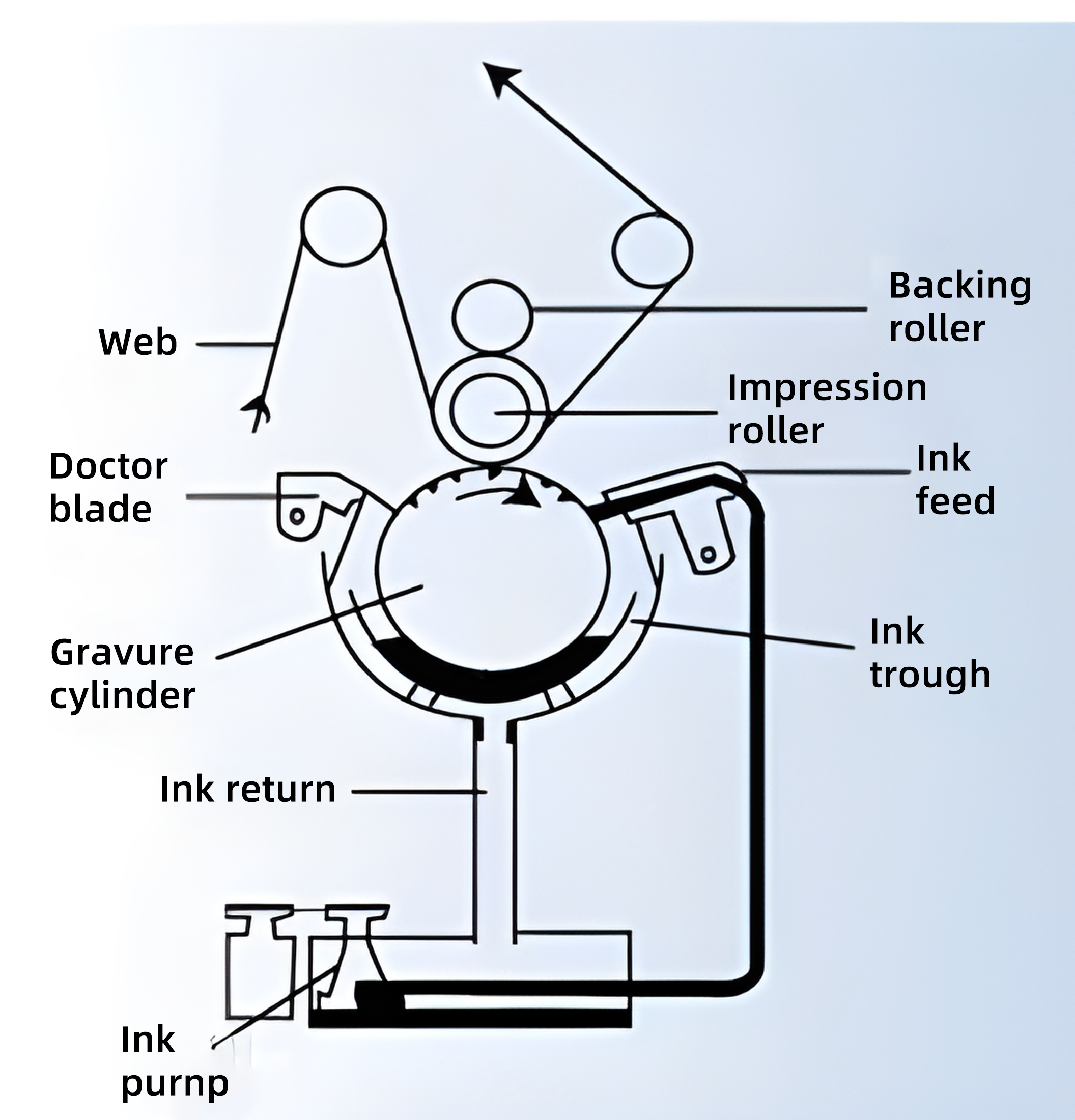

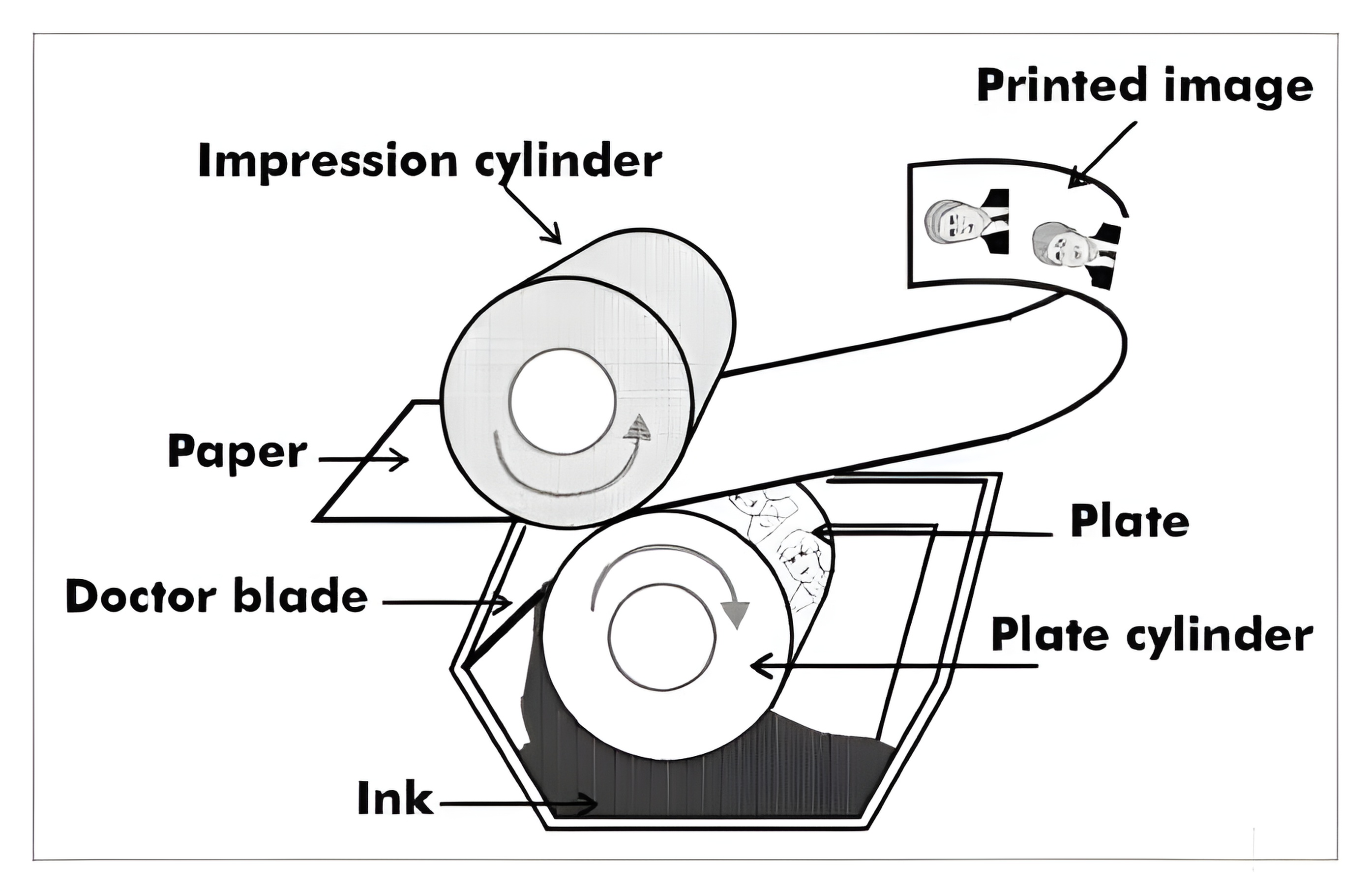

Gravure printing is to make the entire surface of the printing plate coated with ink, and then use a special scraping mechanism to remove the ink from the blank part of the ink, so that the ink is only deposited in the mesh cavities of the graphic part of the ink, and then under the action of a greater pressure, the ink will be transferred to the surface of the substrate, to obtain the printed matter. Gravure printing est recta printing. In graphic partem printing laminam concavum et gradum concavum cum gradu ad imaginem habet diversas umbras, blank parte printing laminam elevatur et in eodem cylindri planum.

Rotogravure processus est recta translatio methodo ad excudendi onto lignum-pulpam fibra fundatur, synthetica, aut laminated subiecta, comprehendo:

-Films ut pet, Opp, nylon et Pe, PVC, cellophane

-Papers

-Carton Board

-Aluminum ffoyle

Rotogravure Printing Processus

Rotogravure excudendi debitum ad altum gradum automation of printing apparatus, qualis est laminam est bonum, et sic processu operationem simplicior quam lithographic printing, securus ad dominum, processus fluxus est ut sequitur:

Pre-excudendi praeparatio → in cylindrici laminam → adjust color adnotatione → formalis printing → Post-pressing processus

Processum descriptio

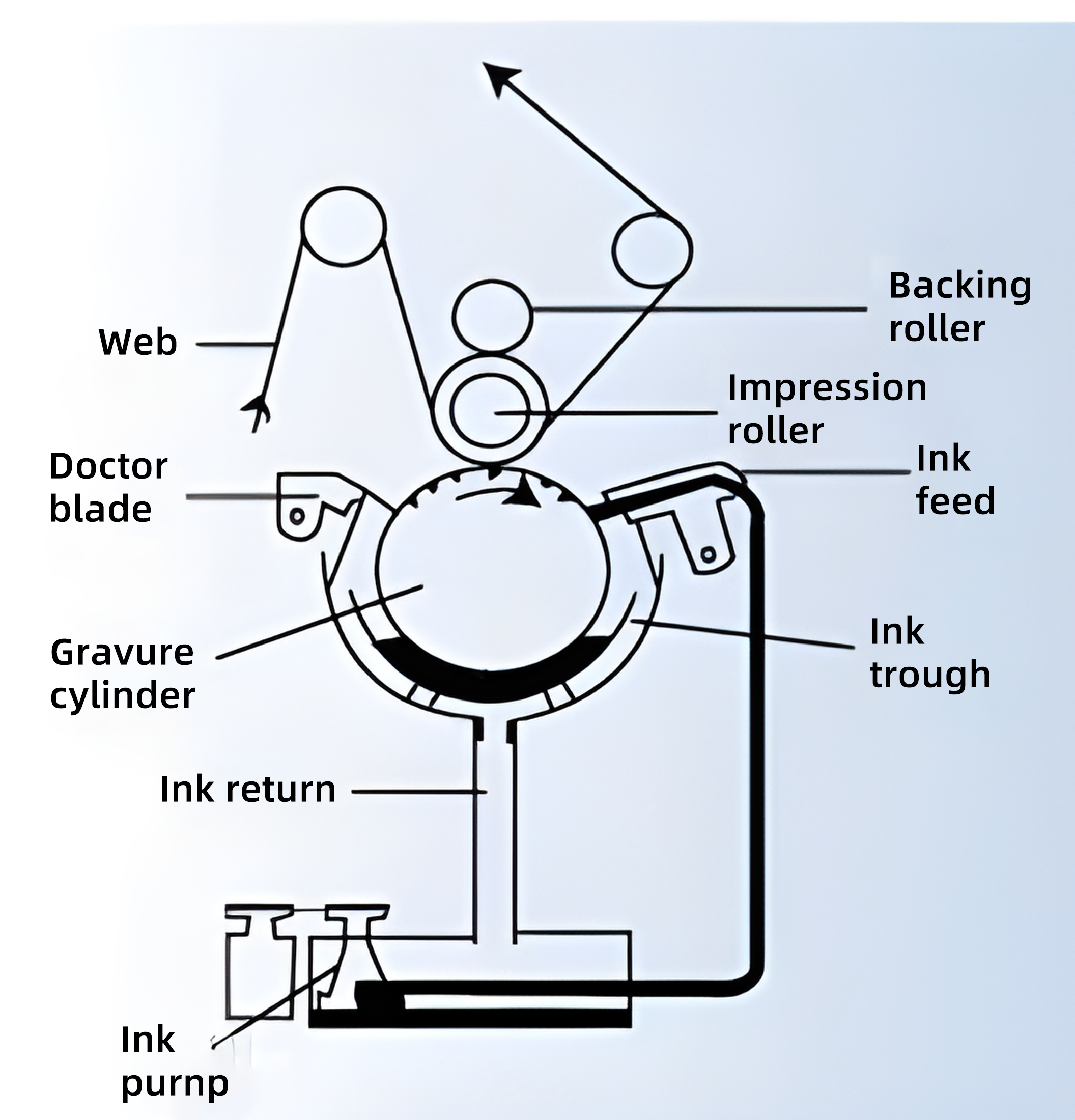

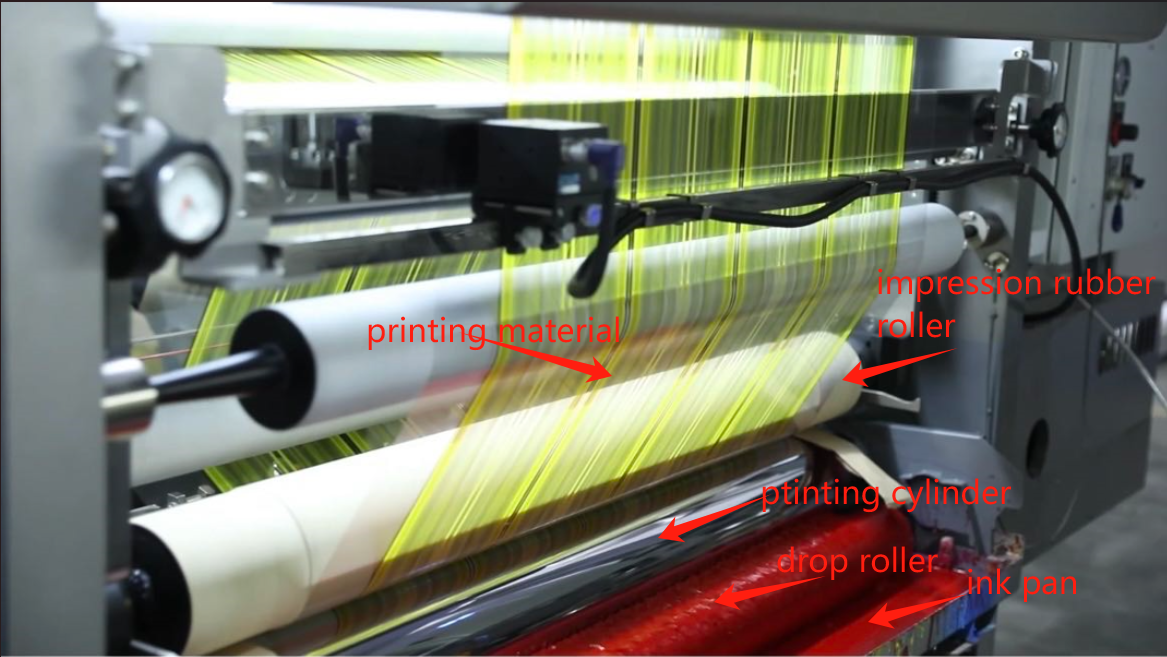

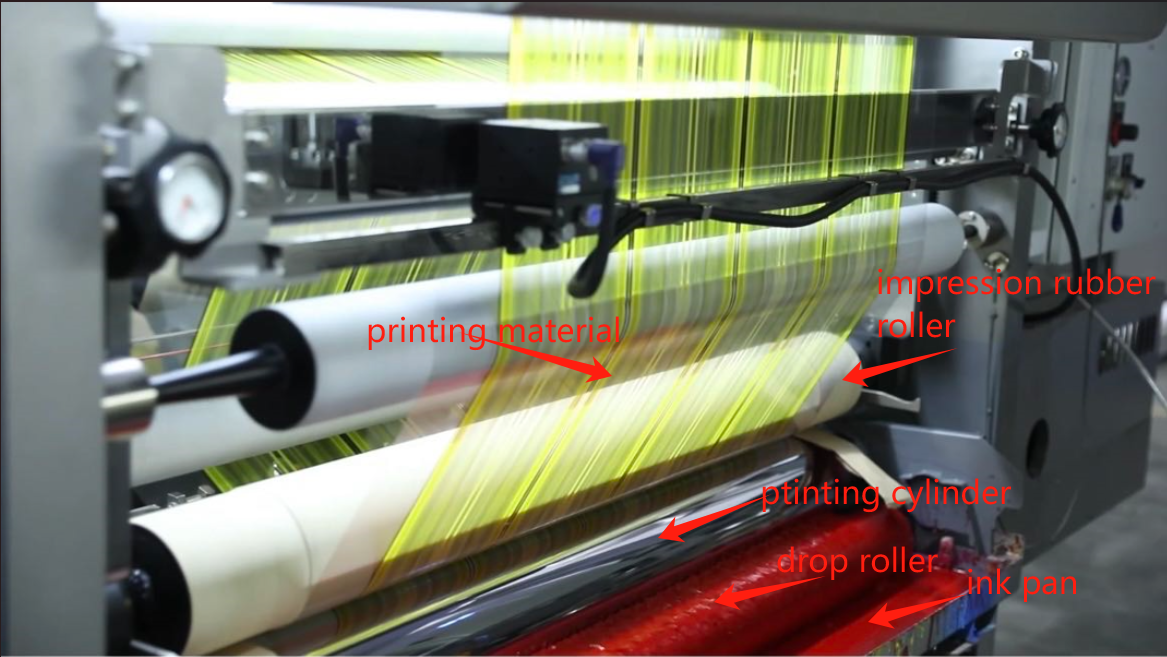

Durante gravus excudendi processus printing cylindrici conuertitur in atramento Pan ubi sculpta cellulis replete cum atramento. Sicut cylindrus conantur patet ex atramento Pan, quilibet excessus atramento remota a medico ferrum. Porro circa, cylindri in contactum cum subiecto, quae est contra eam a rubber operiebat impressionem cylindro.

Et pressura de cylindro, una cum capillaribus trahere subiecti, results in directe translationem atramento a cellulis in excudendi cylindri ad superficiem subiecti. Sicut printing cylindro converterit in atramento Pan, typis area subiecti procedit per dryer et onto altera printing unitas, quae est Northmanni alium colorem aut potest esse varnish vel coating.

Color ad color adnotatione fieri potest via automatic latus et longitudo mandare imperium systems.

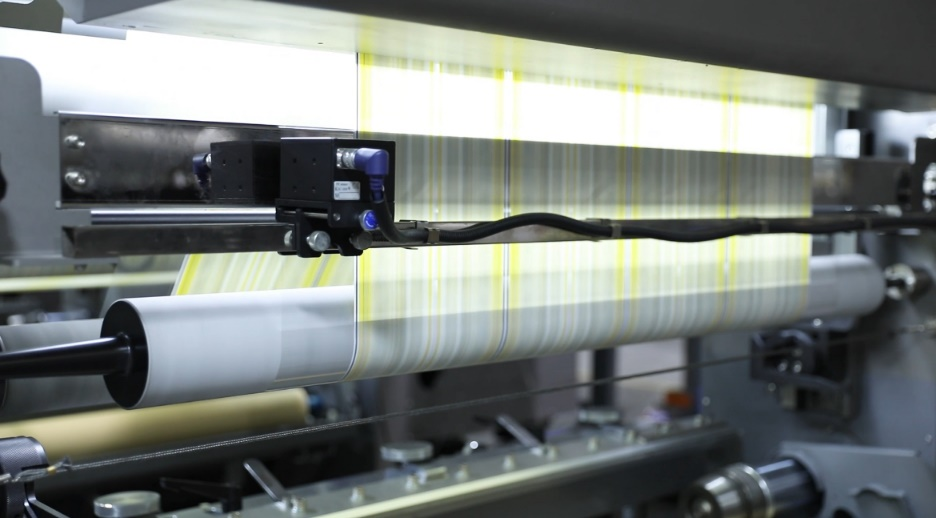

Nam a web-pascitur printing press, postquam quisque color est typis et quis coatings applicantur, in textus est 'rewound' in a perfecta volumine.

Nunc focus in printing processus potest directe afficit printing qualis est maxime momenti links - color adnotatione

Nowadays, in ingens major gravure printing machinas mos utor automatic color adnotatione ratio pro exemplar registration, quod magna amplio in adnotatione efficientiam et printing qualitas.

In textus gravus excudendi apparatus, ibi est automatic overprinting fabrica installed. In fabrica consistit ex scanning caput, pulsus generator, electronic moderatoris, an adjusting motricium, an overprint adjusting cylinder et sic.

When the overprint mark on the printed sheet through the scanning head, the pulse signal will be transmitted to the electronic controller, if the second color of the overprint mark wrong before or after the first color of the mark, the occurrence of the pulse time will be uneven, so the electronic controller to start regulating the motor, so that the first color and the second color of the overprint between the regulating rollers have a small amount of movement, to Eliminate overprinting errores.

Praeterea, ibi sunt etiam in his factoribus, qui potest afficere qualitatem et efficientiam de excudendi, sed non erit convenientem solutions

a) T et atramento est inaequale in color

Et Penomenon periodica atramento color mutationes in typis materiae. Ratio eliminanda includit: corrigere rotunditatis de printing laminam cylindrici, adjusting angulus et pressura de Sprondee aut repositoque ad Spruegee cum nova unum.

b) Fuzzy et Linty Prints

Printed imaginem campester et campester, crustulum, in phaenomenon burrers in ore imaginis. Eliminanda modi includit: removere static electricity ex superficie subiecti, addendo soluts solvents ad atramento, appropriately augendae printing pressura, et adjusting in situ et printing et in.

c) Clausus version

Ink siccatio in printing laminam mesh, aut printing laminam reticulum foraminis repleta est charta capillus, chartam pulveris phaenomenon, vocavit clausus. Eliminanda modi sunt: augmentum contentus de solvents in atramento, reducere celeritate atramento siccatio, in usum excelsum superficiem viribus paper printing.

d) atramento

Phaenomenon maculae adventum in agro parte print. Eliminanda modi includit: addendo difficile atramento miscent oleum, amplio viscositas atramento. Adjust angulus ex Sprondee, crescere printing celeritate et reponere altum-cavum excudendi laminam cum vadum cavum excudendi laminam.

E) Scratch

Sunt vestigia de Springe in print. Eliminanda modi sunt: uti clean atramento sine aliena materia mixta in printing. Adjust viscositas, siccitas et adhaesionem atramento. Uti altus-qualitas Squeegee, adjust angulus inter Springee et printing laminam.

Oyang scriptor consilio engineers resolvitur et optimized apparatus structuram secundum seriem problems in printing processus, et disposito in honorem Sereis Els Rotog Ragur Excudendi Machina de industria solvendis in dolor punctorum et in industria solvendo dolor punctorum et in industria solvendis in points of the users et industria solvendo dolor punctorum de users et industria solvendo dolor punctorum et in industria solvendis.

Rotogravure processum commoda et applications

Processus praebet facultatem translationis atram convenienter, trans lateque densitatum, et ad altum celeritatibus, faciens idoneam applications quod requirere princeps imaginem qualis, ut palaestra, packaging, pittacia, securitatem print, et exornantur printing.

Dura naturae printing cylindris usus facit gravus printing est specimen processus pro providente excelsum qualis print in ipso longa vel regularly repetit decurrit, tradens sumptus commoda super aliis processibus.

Oyang scientia et scientia

A formidolible innovator, focused in partum valorem pro suo clients, products ex Oyang rotographure press faciens, in tantum tres annos et bonum nomen in Sina in Sinis, et non sunt in terris et regiones in orbem terrarum, et non sunt in printing printing et run in stably.

Aequipa Graece innovator, Oyang habet novum signa in Web-film gravure printing in postulans areas ut flexibilia packaging cum suis Honor® series rotogravure premit . Achieving egregius print results in summus finem laminated flexibilia packaging opposuit novum provocationes ad gravam printing processus, sed technicae progressionis, otium of usu, ieiunium Turnaround tempus et reducitur vasto in Sina et circa mundi electiones pro customers in Sina et circum orbem.